Low-temperature vacuum radiation temperature parameter calibration system and calibration method

A technology of radiation temperature and low-temperature vacuum, applied in the field of low-temperature vacuum low-temperature vacuum radiation temperature parameter calibration system, can solve problems such as hidden dangers, difficult calibration of on-orbit space radiation temperature parameters, and inability to evaluate the accuracy of test data, so as to maintain consistency, Improving the calibration accuracy and designing a reasonable and ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

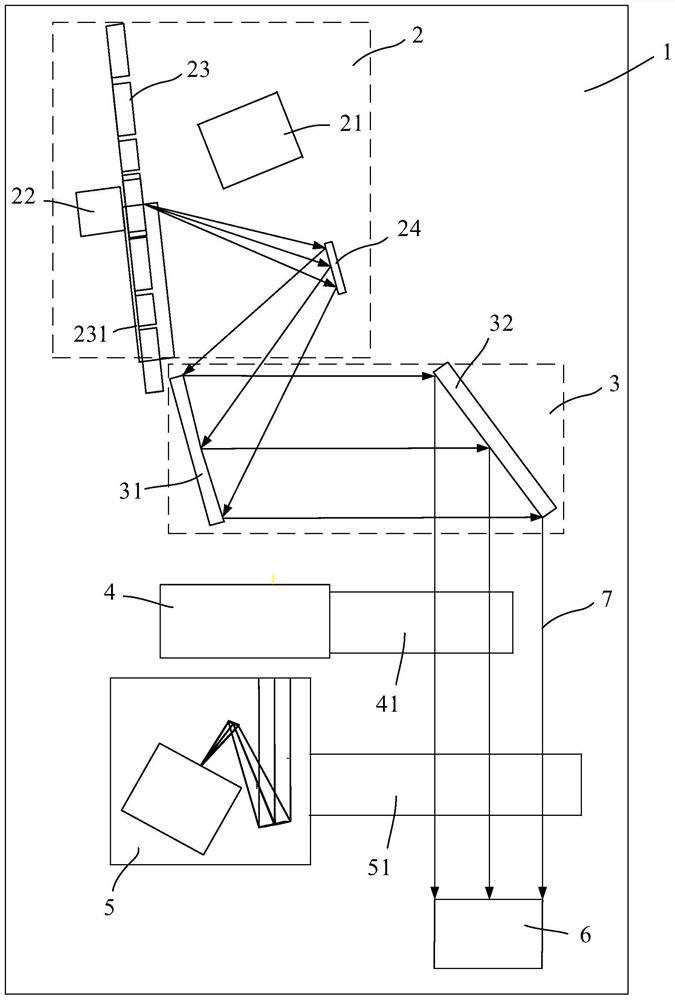

[0050] Example 1, see figure 1 , Figure 7 to Figure 10 According to an aspect of the present invention, an embodiment of the present invention provides a low-temperature vacuum radiation temperature parameter calibration system, including: a vacuum cooling chamber 1 for simulating a low-temperature vacuum environment;

[0051] An infrared temperature difference radiation emitting device 2, which is arranged in the vacuum cooling chamber 1, and is used to emit the first infrared radiation with a set temperature difference;

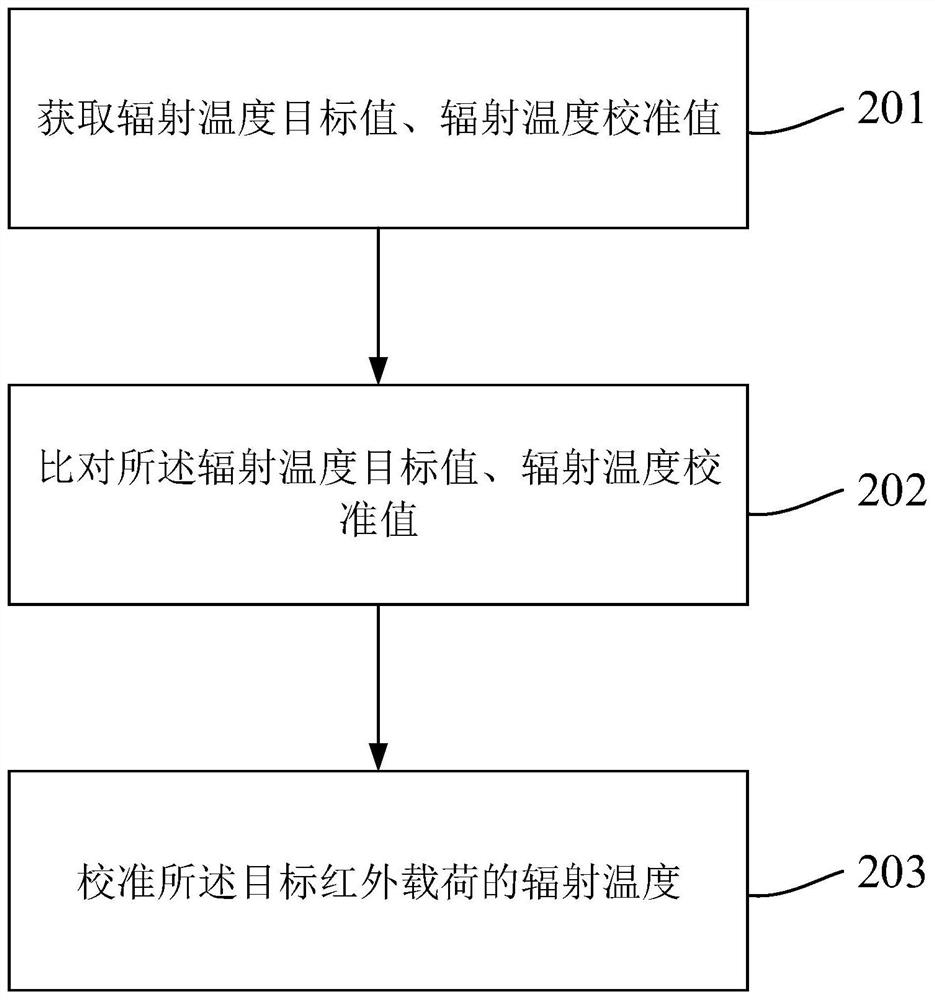

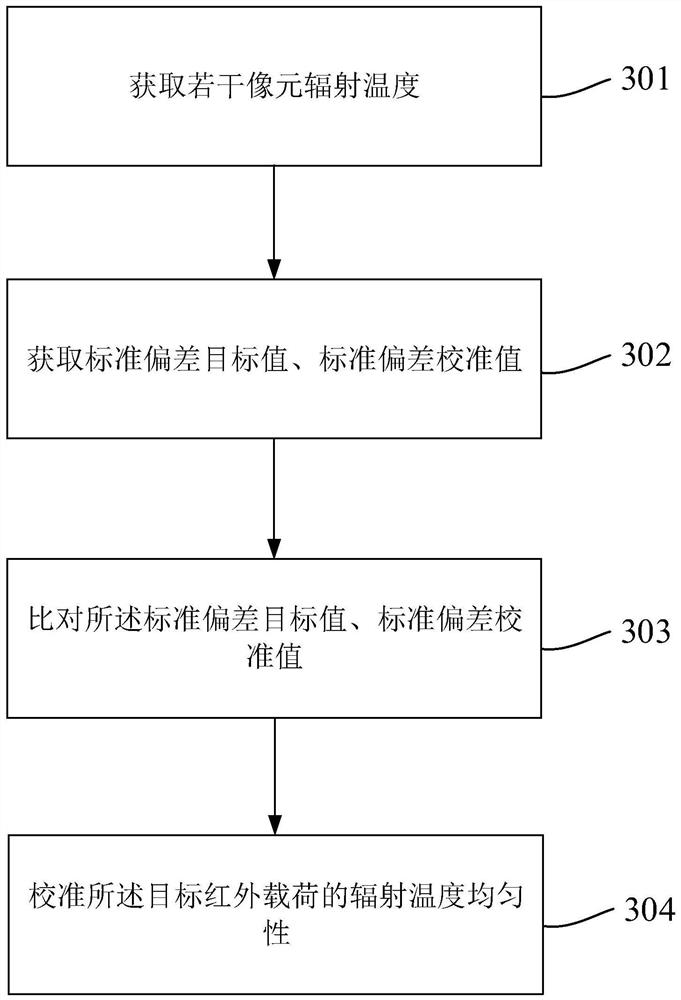

[0052] A collimating optical device 3, which is arranged in the vacuum cooling chamber 1 corresponding to the infrared temperature difference radiation emitting device 2, is used to receive the first infrared radiation and transmit the first infrared radiation to the target after collimation and processing The infrared load 6 is used for the target infrared load 6 to perform noise equivalent temperature difference calibration and / or minimum resolvable tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com