Air turbine starter turbine rotor elastic support design optimization method

An elastic support and air turbine technology, which is applied in design optimization/simulation, multi-objective optimization, computational theoretical chemistry, etc., can solve the problem of not being able to actually exert the effect of the squeeze oil film damper, the structure of the lubricating oil pump, and the structure of the air turbine starter that cannot be installed Compact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

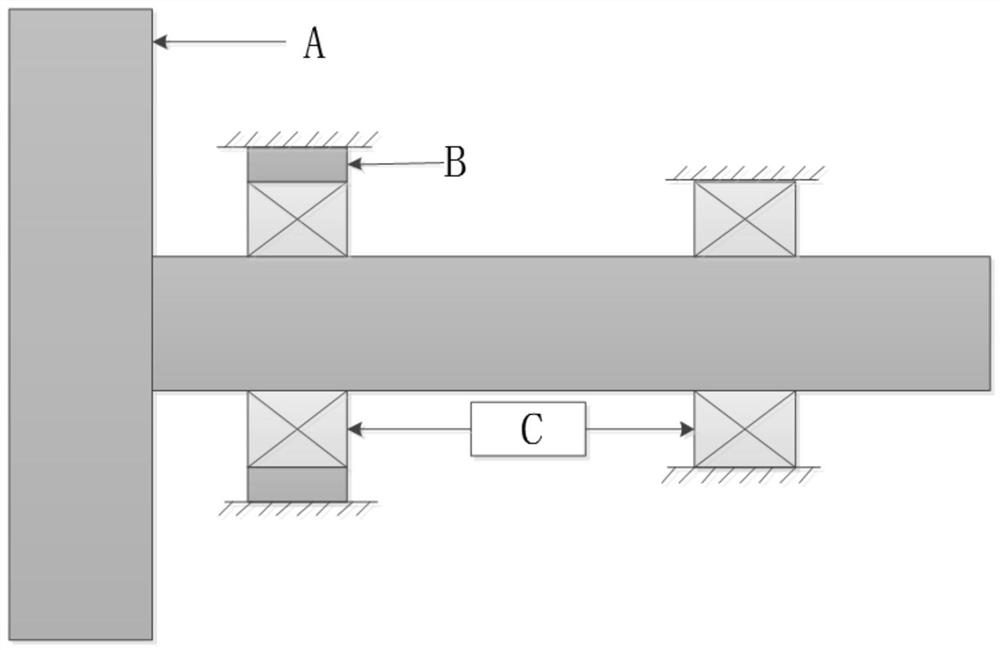

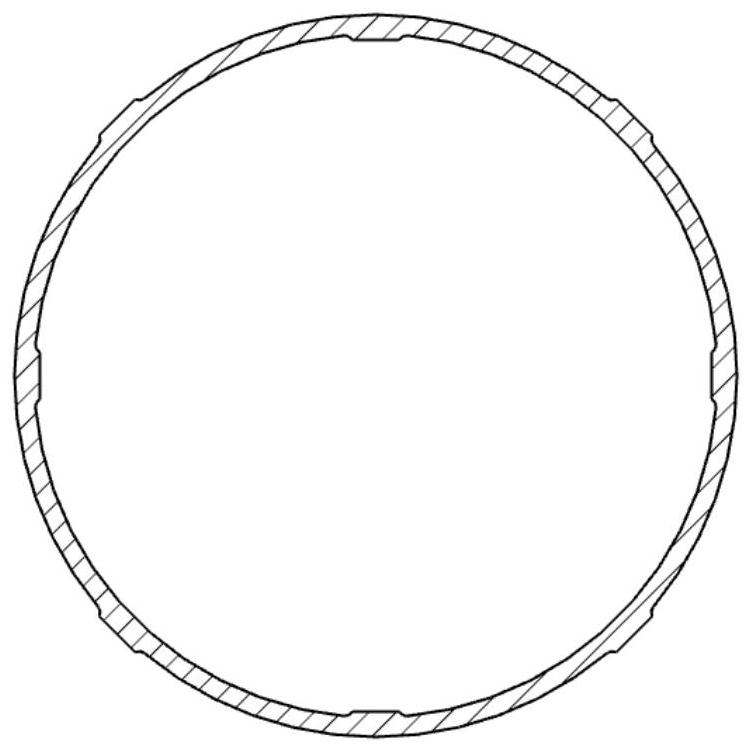

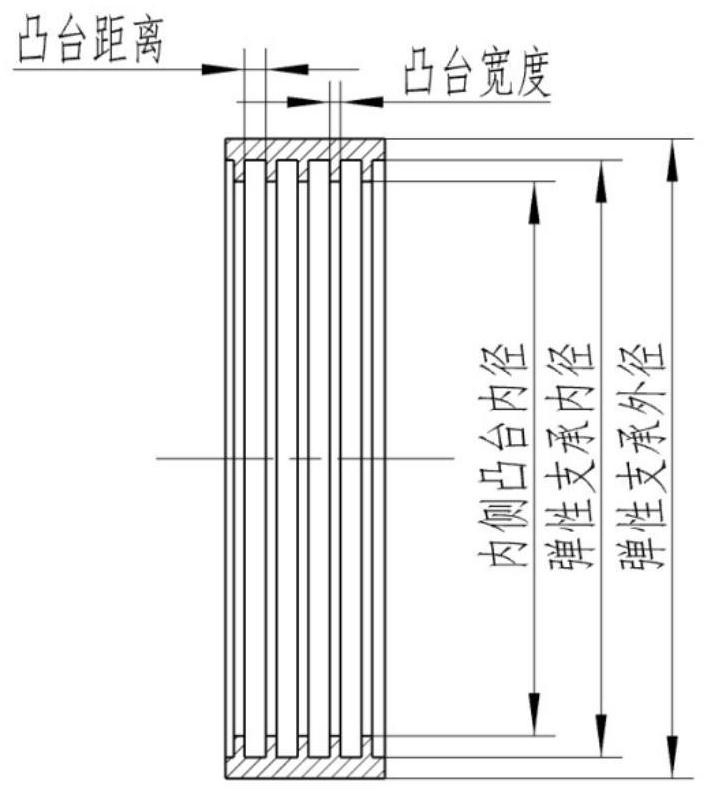

[0039] Below in conjunction with the cantilevered supporting rotor of a certain type of air turbine starter, the present invention will be further described through a design optimization process and accompanying drawings of an elastic supporting structure matched with its supporting bearing to meet the requirements of the rotor dynamic characteristics, but the present invention Not limited to the design and optimization of elastic bearings for turbine rotors of air turbine starters.

[0040]The invention discloses an elastic support design method that is based on finite element software, considers strength, life, assembly requirements and meets rotor vibration characteristic adjustment requirements, can automatically iteratively calculate, reduces time cost, and is closer to engineering practice. The designer only needs to consider the structural form of the elastic support and the safety margin requirements according to the disclosed process of the present invention, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com