Start control system and method of X-ray machine

A technology of X-ray machine and soft start, which is applied in the control of radiological diagnostic equipment, instruments used for radiological diagnosis, radiological diagnostic testing/calibration, etc. It can solve problems such as stability and filament current false protection, so as to simplify the production and debugging steps, reduce labor and time costs, and reduce current overshoot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

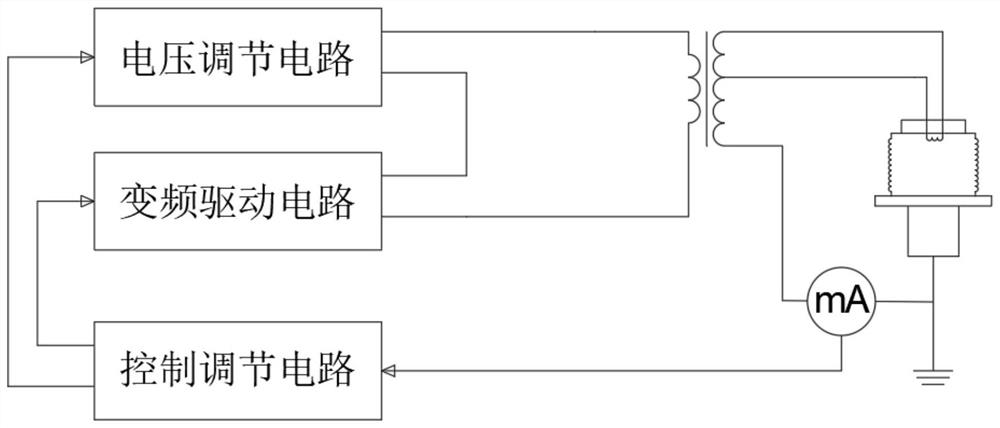

[0035] Such as figure 1 As shown, the start-up control system of the X-ray machine of the present invention includes a voltage regulation circuit, a variable frequency drive circuit, and a control regulation circuit. The control regulation circuit is respectively connected with the voltage regulation circuit and the variable frequency drive circuit, the control regulation circuit detects the mA current of the X-ray machine, controls the variable frequency drive circuit to adjust the operating frequency, and controls the voltage regulation circuit to adjust the working voltage.

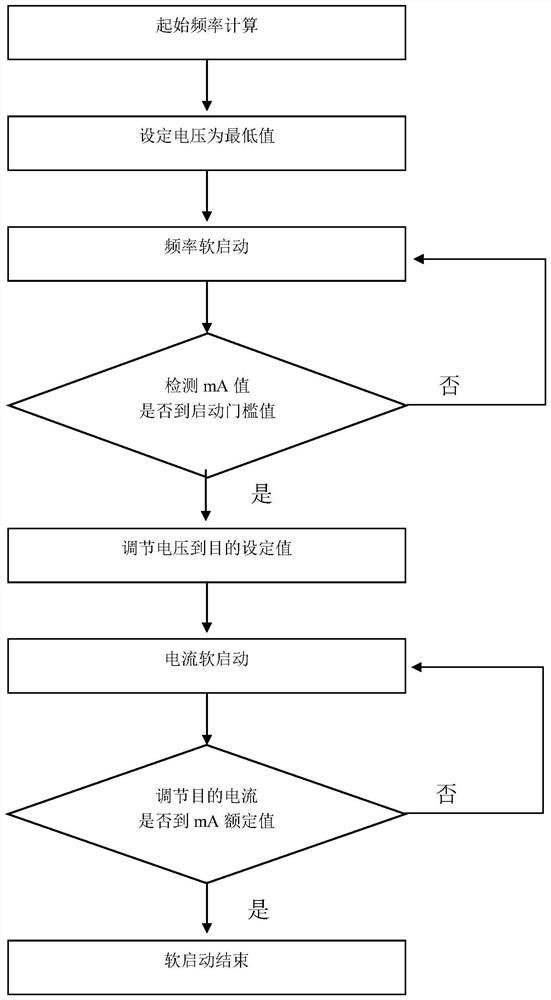

[0036] Such as figure 2 As shown, the start-up control method of the X-ray machine of the present invention includes the following steps,

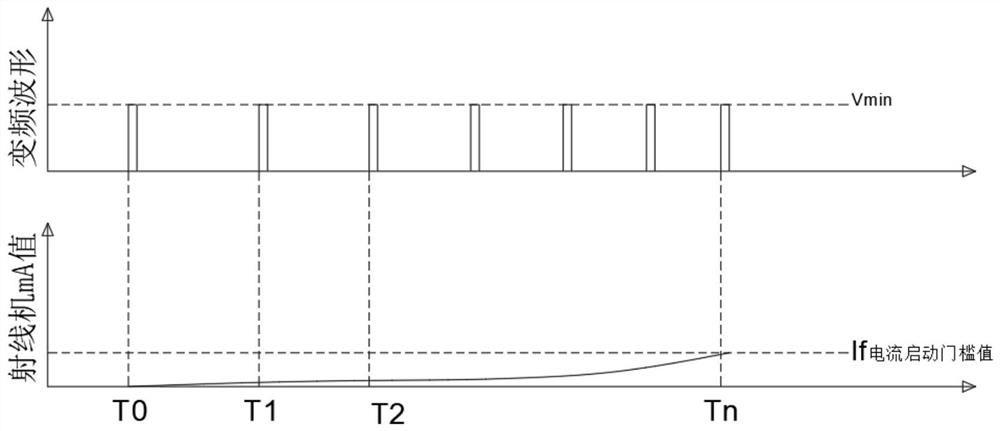

[0037] Step S1 frequency soft start:

[0038] Calculate the starting frequency of variable frequency start, according to the following formula:

[0039] f s = K 2 / H

[0040] In the formula, H is the high pulse width of the set rated frequency; K 2 is the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com