Vacuum module of pulsation vacuum sterilizer

A technology of pulsating vacuum and sterilizer, which is applied in sanitary equipment for toilets, water supply devices, heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

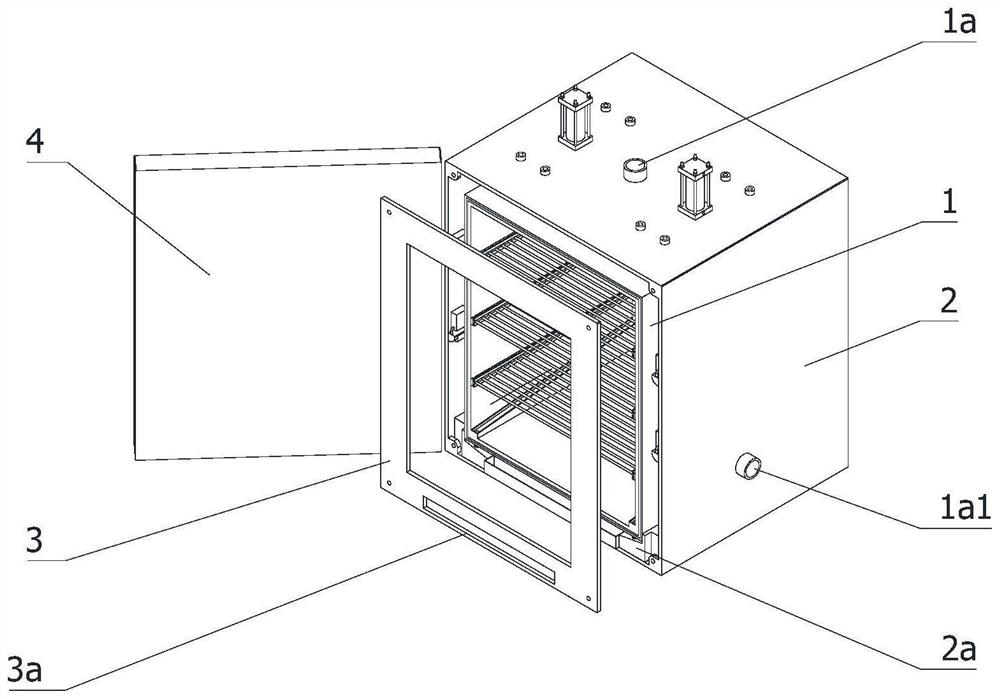

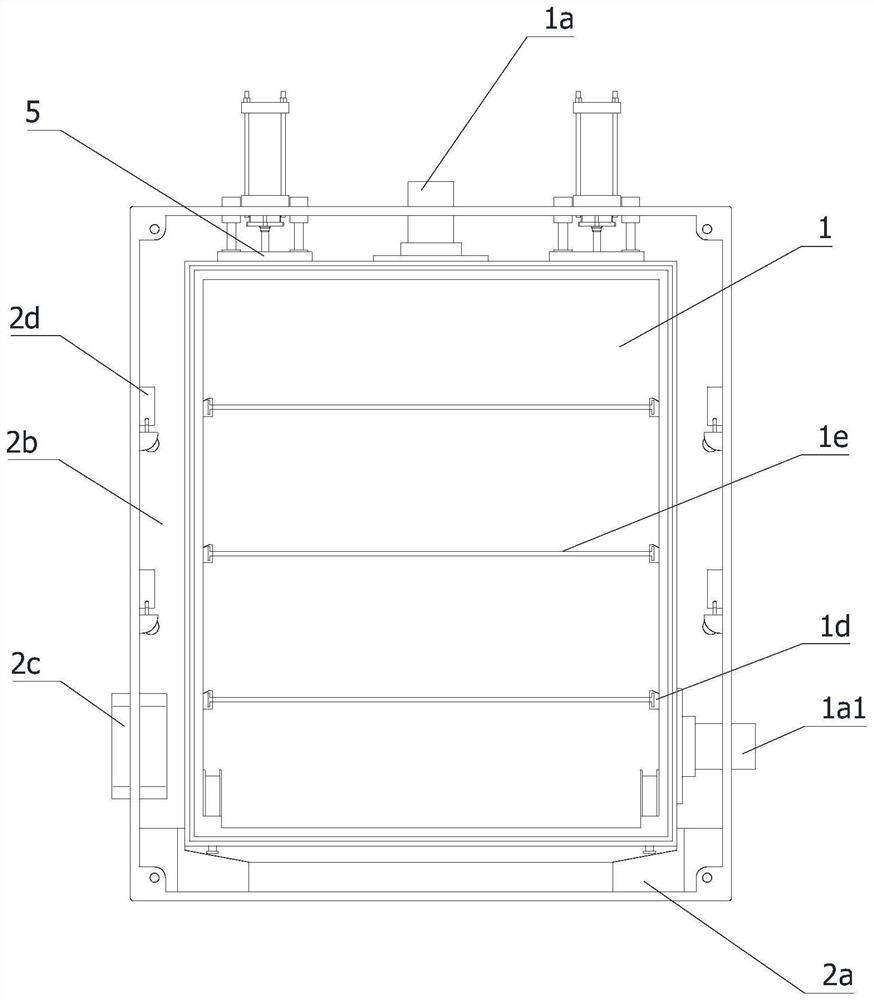

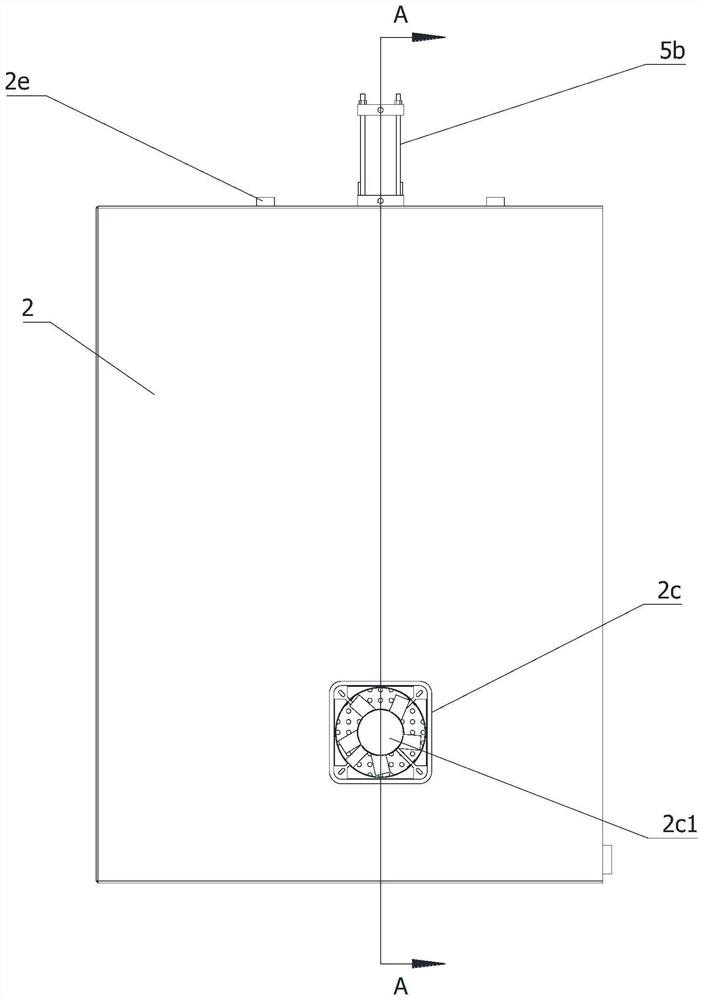

[0040] Such as Figure 1 to Figure 10 As shown, this application provides:

[0041] A vacuum module of a pulsating vacuum sterilizer, comprising a vacuum sterilizing box connected to a water ring vacuum pump and a steam generating device. The vacuum sterilizing box is composed of an inner vacuum box 1 and an outer packaging shell 2 with openings facing the same side. The vacuum box 1 is installed on the limit seat 2a at the bottom of the outer packaging shell 2, and the opening between the inner vacuum box 1 and the outer packaging shell 2 is closed by the closing panel 3, and the closing panel 3 makes the gap between the inner vacuum box 1 and the outer packaging shell 2 There is a sealed cavity 2b b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com