Automobile oil pipe joint machining device and machining method thereof

A technology for oil pipe joints and processing devices, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of unstable clamping, vibration noise, low transmission efficiency, low failure rate, etc., and achieve fast and stable conversion. The effect of improving transmission efficiency and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

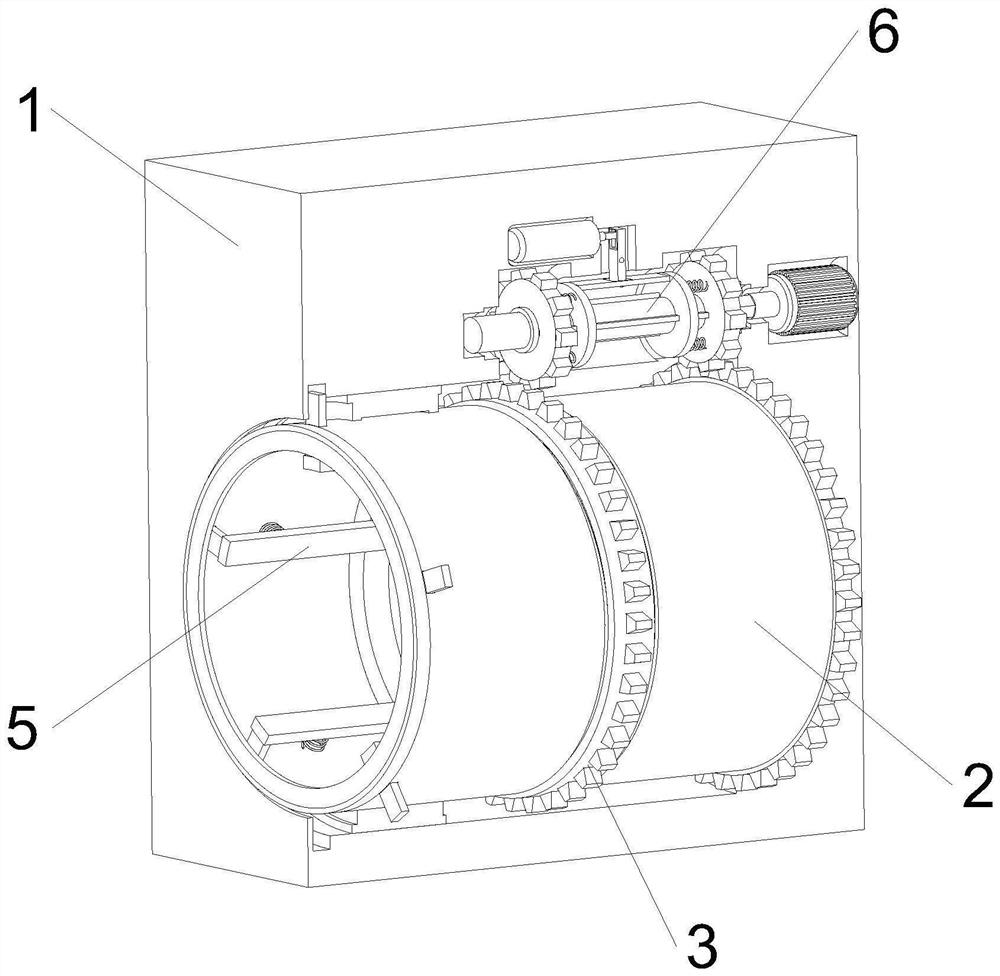

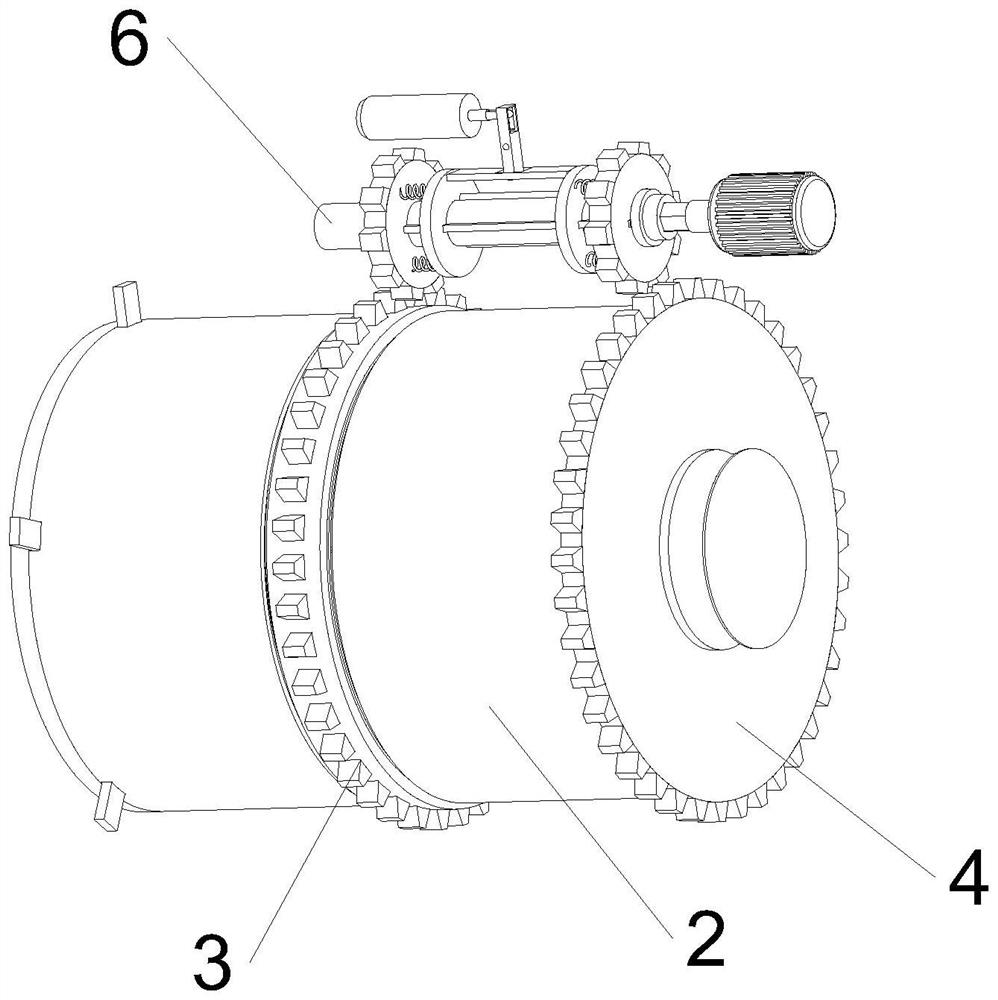

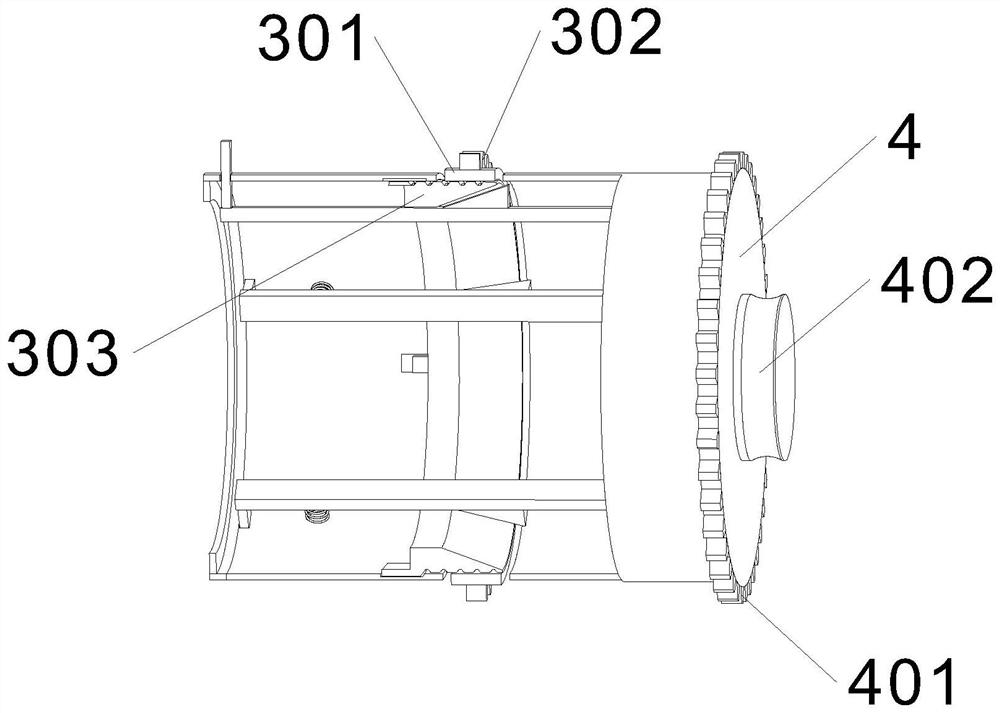

[0038] see Figure 1-Figure 5 As shown, the outer frame 1 is an integral part of the equipment, and other equipment is externally connected to the outside, and the rotating cylinder 2, the driving mechanism 6, the driving cylinder 13, the connecting rod 12 and the push plate 11 connected to the driving cylinder 13 are connected in rotation. , the drum 2 is divided into two parts by the locking mechanism 3, wherein the front part of the drum 2 is provided with an opening, which can be put into the workpiece to be processed, and the rear part of the drum 2 is fixedly installed with a drive plate 4, and the outside of the drive plate 4 is fixedly connected with a bearing Bearing 402, the rotation of the drum 2 in the outer frame 1 is supported by bearings, the outer wall of the front part of the drum 2 and the outer wall of the bearing bearing 402 are all provided with bearings, and the rotation of the drum 2 in the bearing reduces the time when the drum 2 rotates. The resistance...

Embodiment 2

[0040] see Figure 6-Figure 7 As shown, the driving mechanism 6 is also arranged inside the outer frame 1, and the driving mechanism 6 is located above the drum 2. The driving mechanism 6 includes a main driving shaft 601, a hexagonal output shaft 602, a servo motor 603 and a side locking plate 604. The main driving shaft One end of 601 is slidably connected inside the outer frame 1, and the main drive shaft 601 can rotate and translate in the axial direction inside the outer frame 1. The other end of the main drive shaft 601 is provided with a hexagonal interface, and the main drive shaft 601 slides through this structure Connected to the outer wall of the hexagonal output shaft 602, through this structure, the hexagonal output shaft 602 can drive the main drive shaft 601 to rotate without slipping, and at the same time, the main drive shaft 601 can slide freely in the axial direction on the hexagonal output shaft 602, ensuring The freedom of movement of the main drive shaft ...

Embodiment 3

[0042] see Figure 6-Figure 8 As shown, the outer wall of the main drive shaft 601 is also fixedly connected with two sets of support plates 8, the two sets of support plates 8 are located between the two sets of transmission gears 7, the support plates 8 are fixedly connected with the main drive shaft 601, so that the support plates 8 can Drive main drive shaft 601 to move, be provided with push plate 11 between two groups of support plates 8, the length of push plate 11 is less than the distance between two groups of support plates 8, make push plate 11 and support plate 8 when not working Keep slack to reduce the wear and tear of the contact between the support plate 8 and the push plate 11. The middle part of the push plate 11 is rotatably connected with a connecting rod 12, and the middle part of the connecting rod 12 is connected to the inside of the outer frame 1 through a rotating shaft, so that the connecting rod 12 can rotate around the middle rotating shaft. The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com