Method for preparing high-quality polyisobutene

A polyisobutylene, high-quality technology, applied in the field of preparing high molecular polymers, can solve the problems of long purification time, low production efficiency and high energy consumption, and achieve the effects of shortening purification time, ideal purification effect and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

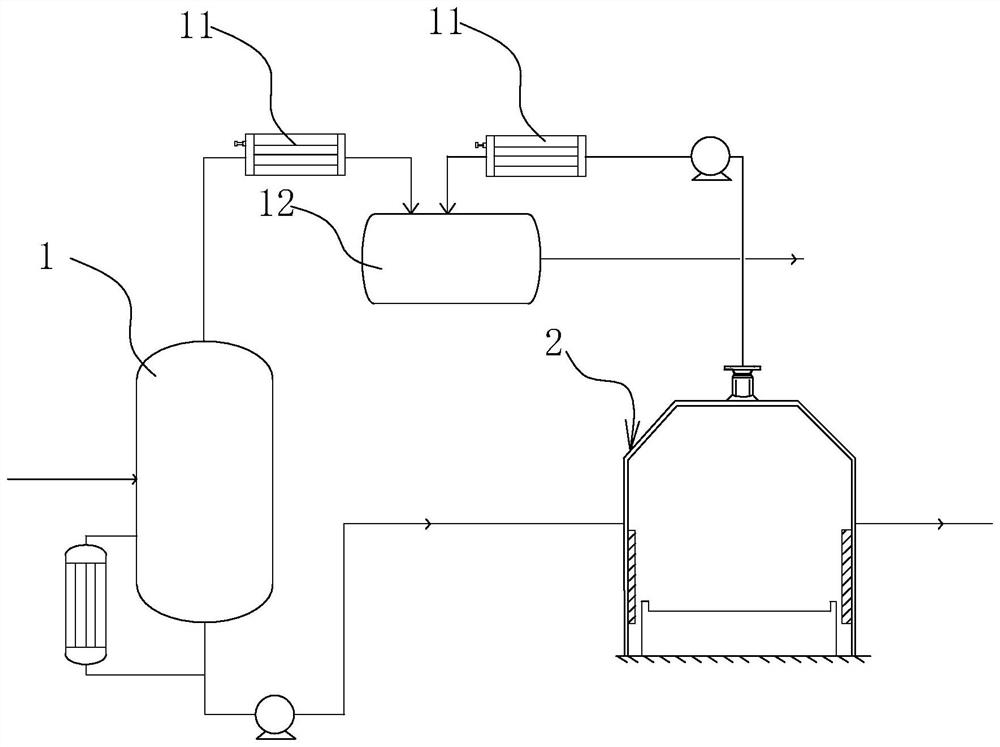

[0033] Such as Figure 1-4 Shown, a kind of method for preparing high-quality polyisobutylene comprises the following steps:

[0034] 1) Add water to the polyisobutene to be treated, wherein the amount of water added per 1 kg of polyisobutene is 0.1 g; the polyisobutene to be treated is polyisobutene generated by polymerization.

[0035] 2) The polyisobutene added with water is passed into the degassing kettle 1, and after the volatile phase is removed, the state of the polyisobutene becomes viscous liquid;

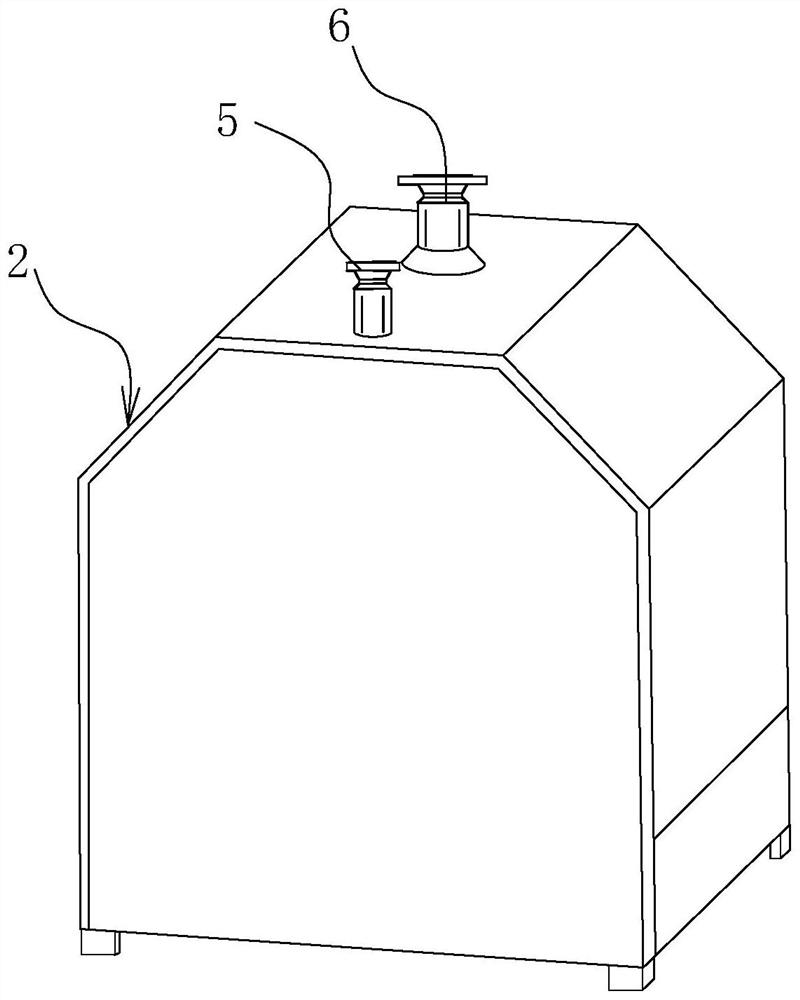

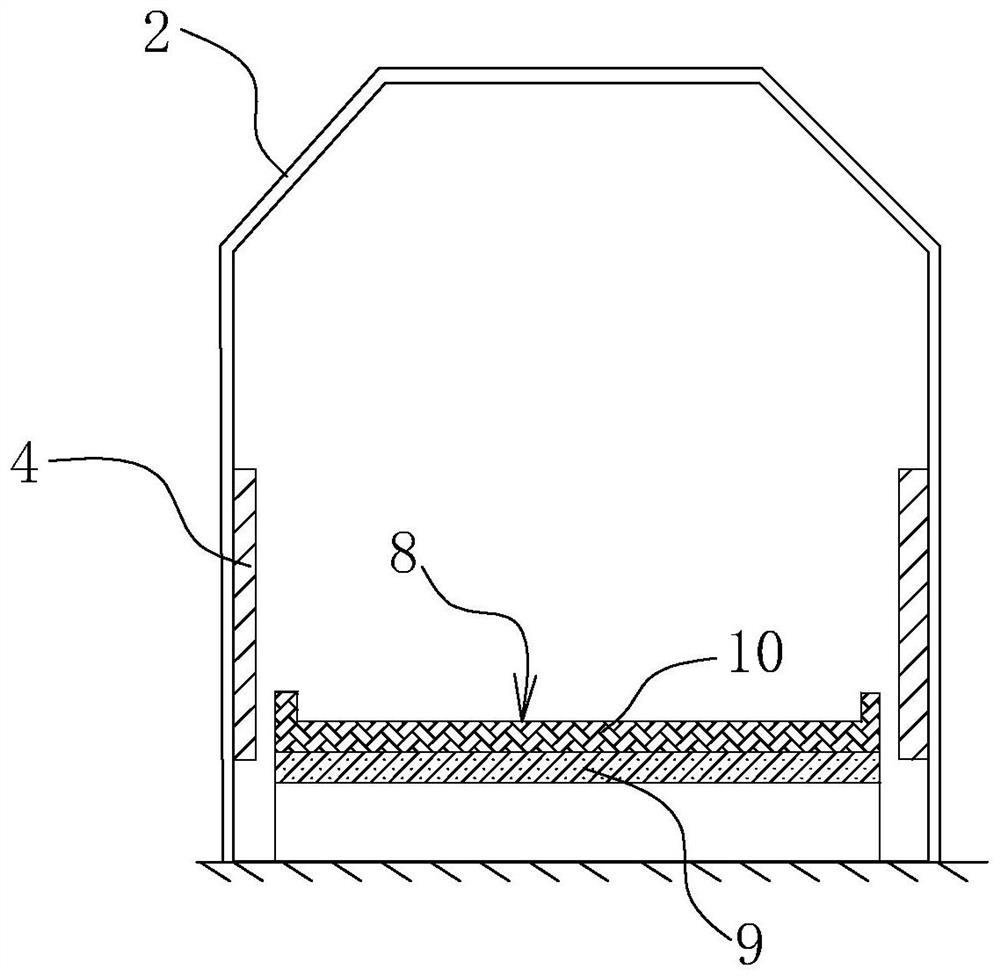

[0036] 3) Pass the polyisobutene into the microwave heating chamber 2, scrape the polyisobutene into flakes by the scraper 3, start the microwave heater 4, and obtain the purified polyisobutene after removing the volatile phase.

[0037] In step 3), the polyisobutylene is fed into the microwave heating chamber 2 through the feed pipe 5 of the microwave heating chamber 2, and the polyisobutylene is scraped into flakes by the scraper 3. After starting the microwave heater ...

Embodiment 2

[0043] Such as Figure 1-4 Shown, a kind of method for preparing high-quality polyisobutylene comprises the following steps:

[0044] 1) Add water to the polyisobutene to be treated, wherein the amount of water added per 1 kg of polyisobutene is 2 grams;

[0045] 2) The polyisobutene added with water is passed into the degassing kettle 1, and after the volatile phase is removed, the state of the polyisobutene becomes viscous liquid;

[0046] 3) Pass the polyisobutene into the microwave heating chamber 2, scrape the polyisobutene into flakes by the scraper 3, start the microwave heater 4, and obtain the purified polyisobutene after removing the volatile phase.

[0047] In step 3), the polyisobutylene is fed into the microwave heating chamber 2 through the feed pipe 5 of the microwave heating chamber 2, and the polyisobutylene is scraped into flakes by the scraper 3. After starting the microwave heater 4, the microwave heating chamber is The polyisobutene scraped into flakes i...

Embodiment 3

[0053] Such as Figure 1-4 Shown, a kind of method for preparing high-quality polyisobutylene comprises the following steps:

[0054] 1) Add water to the polyisobutene to be treated, wherein the amount of water added per 1 kg of polyisobutene is 5 grams;

[0055] 2) The polyisobutene added with water is passed into the degassing kettle 1, and after the volatile phase is removed, the state of the polyisobutene becomes viscous liquid;

[0056] 3) Pass the polyisobutene into the microwave heating chamber 2, scrape the polyisobutene into flakes by the scraper 3, start the microwave heater 4, and obtain the purified polyisobutene after removing the volatile phase.

[0057] In step 3), the polyisobutylene is fed into the microwave heating chamber 2 through the feed pipe 5 of the microwave heating chamber 2, and the polyisobutylene is scraped into flakes by the scraper 3. After starting the microwave heater 4, the microwave heating chamber is The polyisobutene scraped into flakes i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com