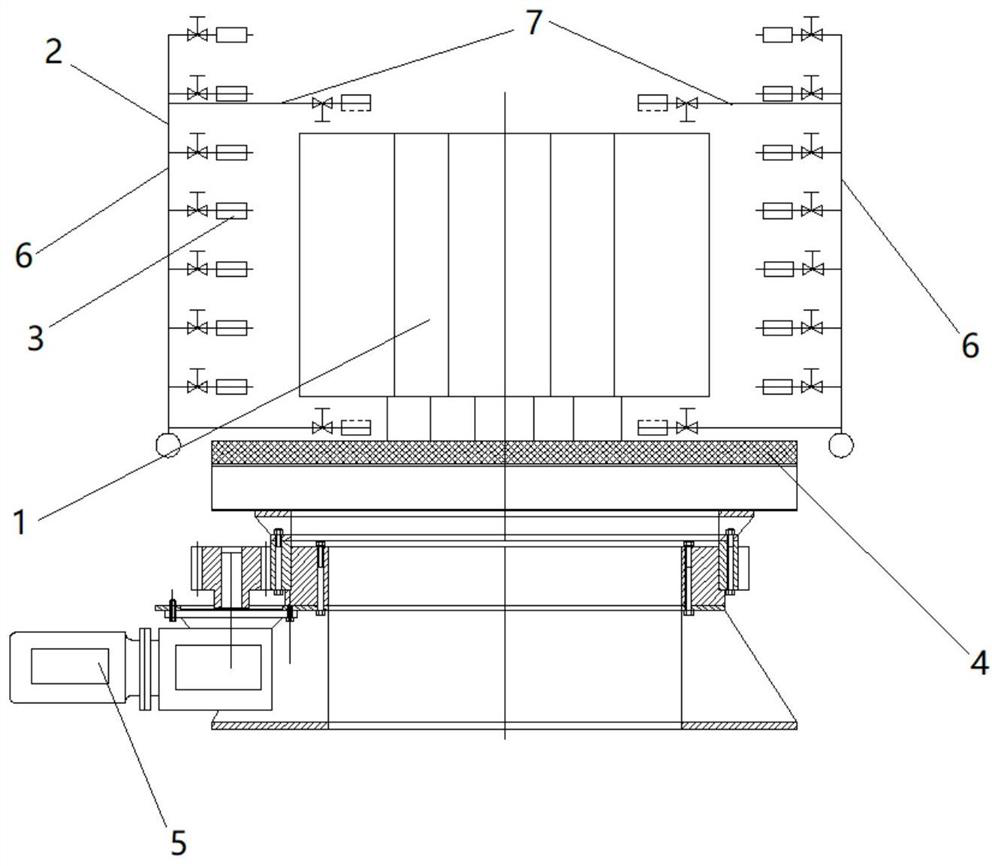

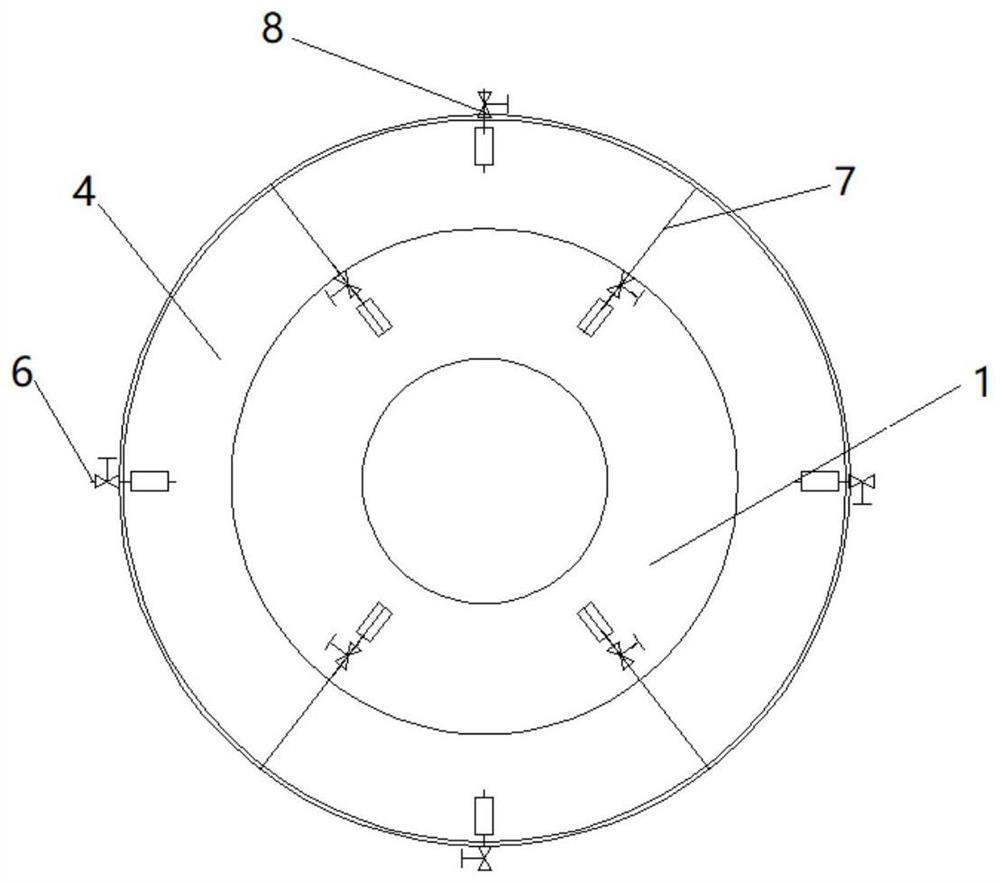

HW type steel horizontal roll collar heat treatment spray quenching device and heat treatment method thereof

A technology of horizontal rollers and section steel, applied in heat treatment furnaces, quenching devices, heat treatment equipment, etc., can solve the problem of low hardness of the side wall of the horizontal roller ring, and achieve the effect of improving overall versatility, uniform hardness, and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The heat treatment process of Φ1400HW steel horizontal roller ring is as follows: a. First, put the HW steel horizontal roller ring into a high-temperature normalizing furnace and place it horizontally; b. Then start power supply and raise the temperature to 450°C, keep it for 10h, then raise the temperature to 960°C, and keep it for 18h ; c, HW-shaped steel horizontal roller ring is out of the furnace for normalizing, use a special spreader to place the HW-shaped steel horizontal roller ring on the rotating platform; d, quickly adjust the distance between the vertical nozzle and the outer circle 400mm, and the distance between the horizontal nozzle and the upper and lower end faces 150mm; e open Spray quenching devices such as high-pressure plunger pumps and rotating platforms are used for spray quenching. The spray quenching time is 38 minutes, and the surface temperature is lowered to 500°C; 28min, put into the furnace and temper; g, the tempering temperature is 540°C...

Embodiment 2

[0034] The heat treatment process of Φ1300HW steel horizontal roller ring is as follows: a. First, put the HW steel horizontal roller ring into a high-temperature normalizing furnace and place it horizontally; b. Then start power supply and raise the temperature to 450°C, keep it for 10h, then raise the temperature to 960°C, and keep it for 16h ; c. The HW-shaped steel horizontal roll ring is out of the furnace for normalizing, and the HW-shaped steel horizontal roll ring is placed on the rotating platform with a special spreader; d. Quickly adjust the vertical nozzle to 450mm from the outer circle, and the horizontal nozzle to 150mm from the upper and lower end faces; e open Spray quenching devices such as high-pressure plunger pumps and rotating platforms are used for spray quenching. The spray quenching time is 40 minutes, and the surface temperature is lowered to 500°C; 30min, put into the furnace and temper; g, the tempering temperature is 540°C, and the time is controlled...

Embodiment 3

[0036]The heat treatment process of Φ1600HW type steel horizontal roll ring is as follows: a. First, put the HW type steel horizontal roll ring into the high temperature normalizing furnace and place it horizontally; b. Then start power supply and raise the temperature to 450°C, keep it for 12h, then raise the temperature to 960°C, and keep it for 20h ; c, HW-shaped steel horizontal roller ring is out of the furnace for normalizing, use a special spreader to place the HW-shaped steel horizontal roller ring on the rotating platform; d, quickly adjust the distance between the vertical nozzle and the outer circle 300mm, and the distance between the horizontal nozzle and the upper and lower end faces 150mm; e open Spray quenching devices such as high-pressure plunger pumps and rotating platforms are used for spray quenching. The spray quenching time is 40 minutes, and the surface temperature is lowered to 500°C; 30min, put into the furnace and temper; g, the tempering temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com