Composite lithium negative electrode and application thereof

A composite lithium and negative electrode technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of lithium dendrites piercing the separator, volume expansion, lithium dendrite growth, etc., to reduce the uneven deposition of lithium ions , Improve the ability of anti-expansion, improve the effect of ion conduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

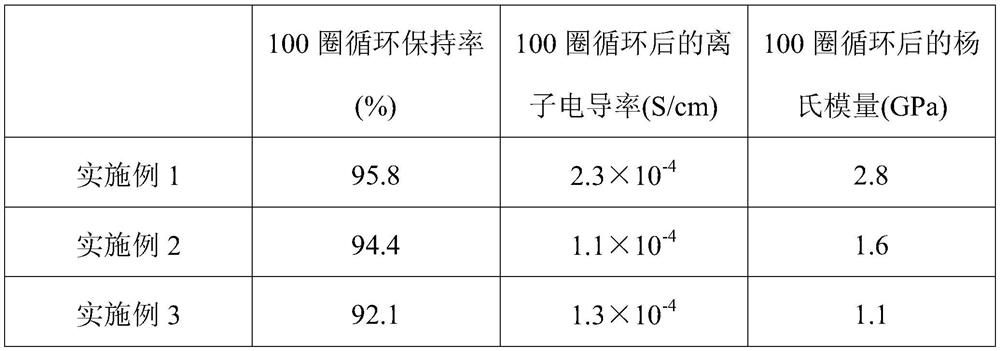

Embodiment 1

[0039] This embodiment provides a composite lithium negative electrode, the lithium negative electrode includes lithium metal and functionalized silicon dioxide;

[0040] The functionalized silica is silica functionalized with carboxyl, carbonyl and hydroxyl, and the molar ratio of carboxyl, carbonyl and hydroxyl is 1:1:1;

[0041] The Young's modulus of the functionalized silica is 2.9GPa, and the ion conductivity is 2.4×10 -4 S / cm, particle size D 50 300nm;

[0042] The preparation method of the composite lithium negative electrode comprises the following steps:

[0043] Under an argon atmosphere, stirring and mixing molten lithium metal and functionalized silicon dioxide, and cooling to obtain the composite lithium negative electrode.

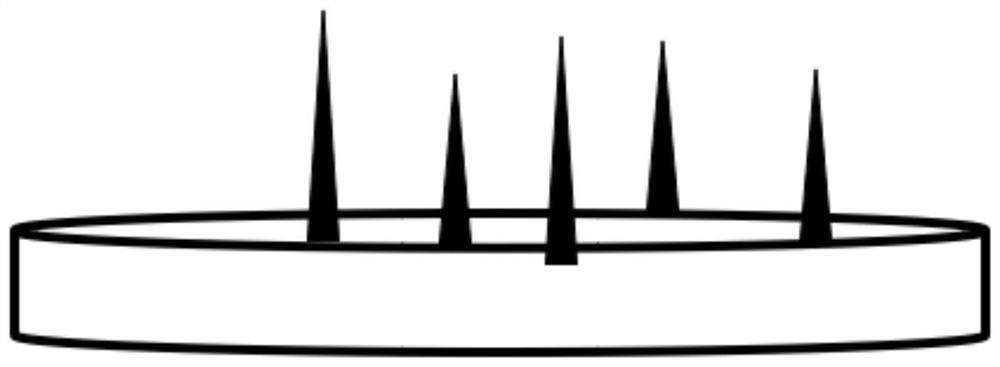

[0044] The schematic diagram of the surface state of the composite lithium negative electrode described in this embodiment after 100 cycles is as follows figure 1 shown.

Embodiment 2

[0046] This embodiment provides a composite lithium negative electrode, the lithium negative electrode includes lithium metal and functionalized silicon dioxide;

[0047] The functionalized silicon dioxide is silicon dioxide functionalized with a carbon-carbon double bond and a nitro group, and the molar ratio of the carbon-carbon double bond to a nitro group is 1:3;

[0048]The Young's modulus of the functionalized silica is 2GPa, and the ion conductivity is 1.1×10 -4 S / cm, particle size D 50 100nm;

[0049] The preparation method of the composite lithium negative electrode comprises the following steps:

[0050] Under an argon atmosphere, stirring and mixing molten lithium metal and functionalized silicon dioxide, and cooling to obtain the composite lithium negative electrode.

Embodiment 3

[0052] This embodiment provides a composite lithium negative electrode, the lithium negative electrode includes lithium metal and functionalized silicon dioxide;

[0053] The functionalized silica is silica functionalized with a carbon-carbon triple bond and an aldehyde group, and the molar ratio of the carbon-carbon triple bond to the aldehyde group is 1:10;

[0054] The Young's modulus of the functionalized silica is 1.2GPa, and the ion conductivity is 1.3×10 -4 S / cm, particle size D 50 600nm;

[0055] The preparation method of the composite lithium negative electrode comprises the following steps:

[0056] Under a helium atmosphere, stirring and mixing molten lithium metal and functionalized silicon dioxide, and cooling to obtain the composite lithium negative electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com