Allium fistulosum combine harvester

A technology for combine harvesters and shallots, which is applied in the direction of digging harvesters, harvesters, agricultural machinery and tools, etc., can solve the problems of too much manpower consumption, high labor intensity, and low utilization rate of tools, so as to improve harvesting efficiency, Avoid clutter and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

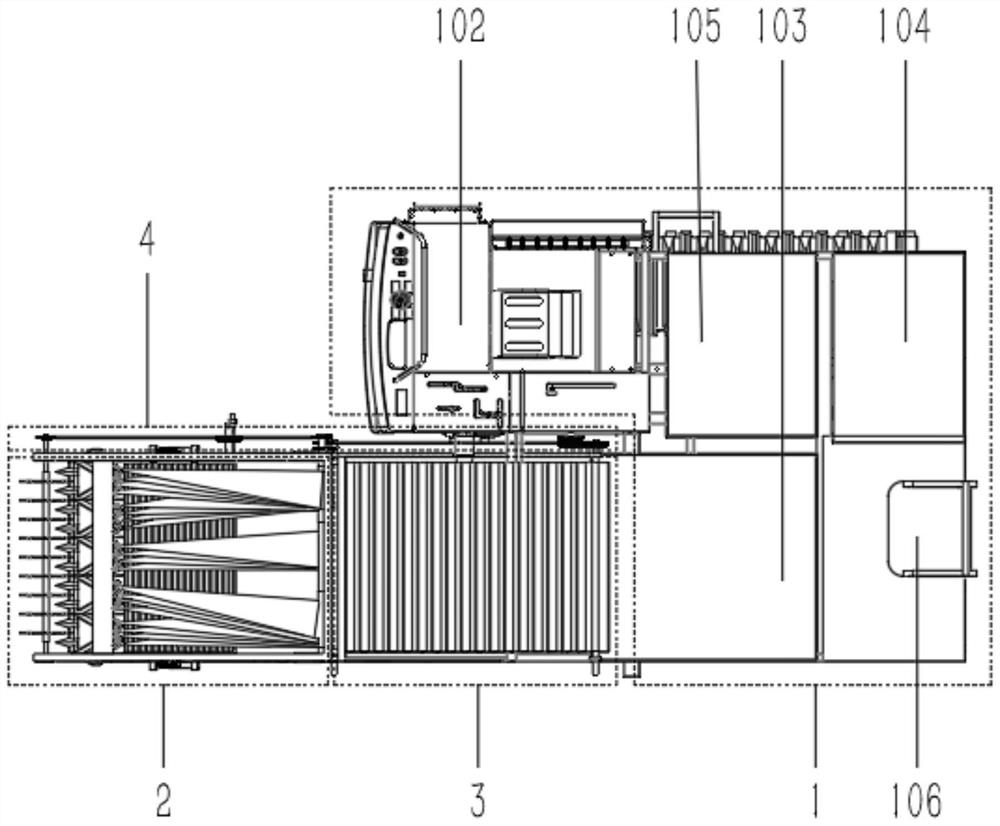

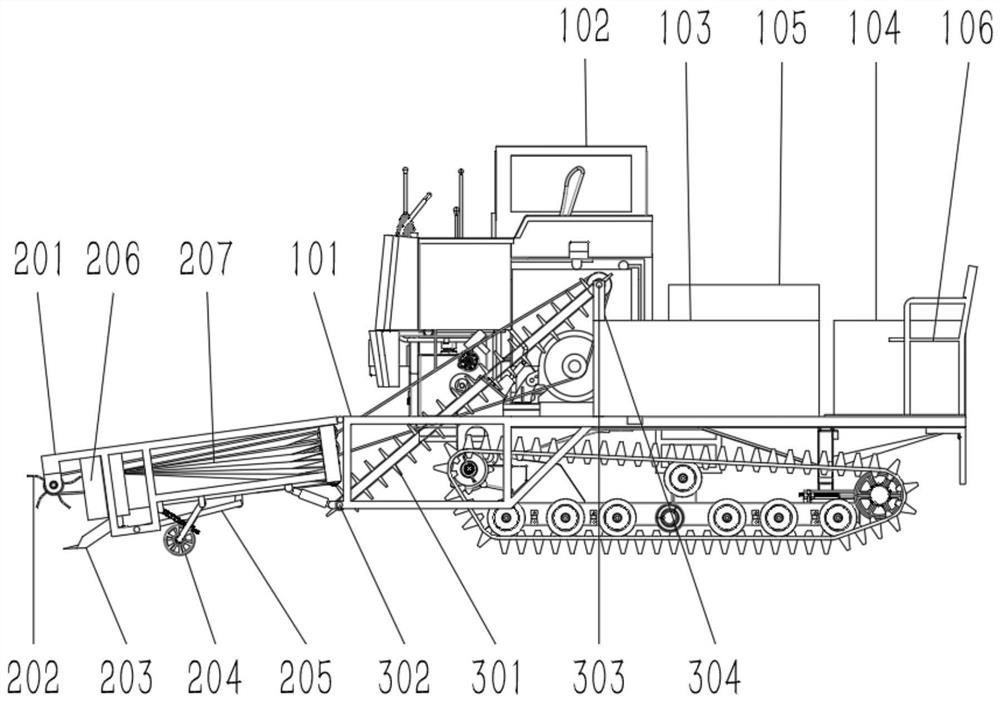

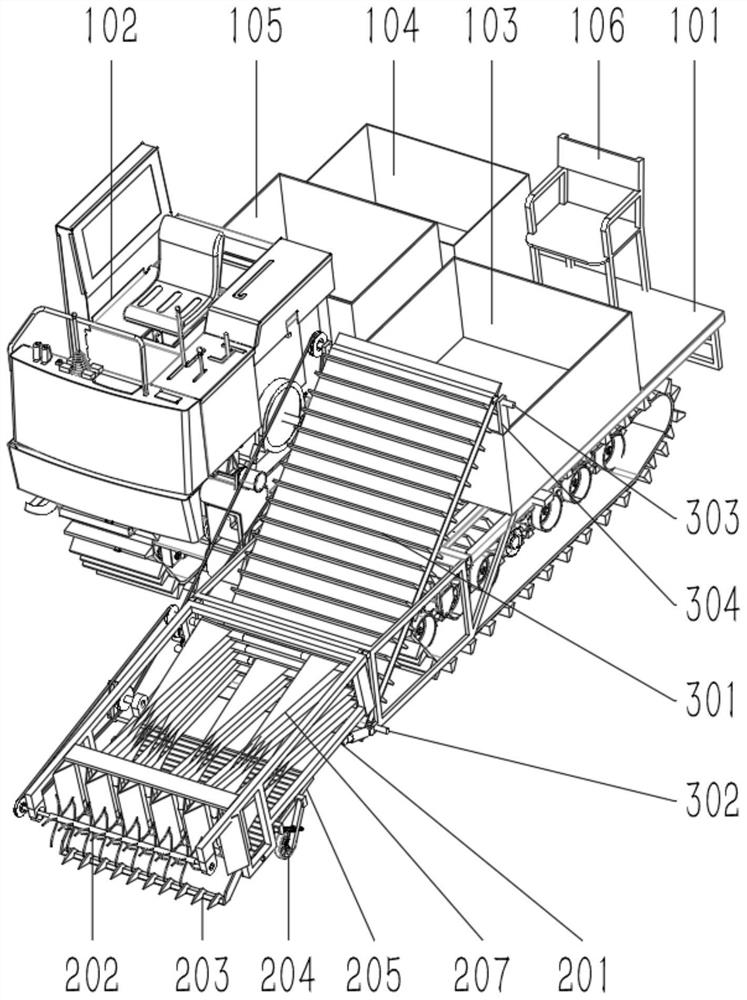

[0032] Such as figure 1 Shown is a preferred embodiment of the shallot combine harvester of the present invention, the shallot combine harvester includes a chassis walking device 1, a harvesting device 2, a conveying lifting device 3 and a transmission device 4; the harvesting device 2. At the front end of the chassis traveling device 1, it is located in front of the conveying and lifting device 3, and the conveying and lifting device 3 is installed at the front of the chassis traveling device 1; Device 3 is connected.

[0033] Such as Figure 2-9 As shown, the chassis walking device 1 includes a chassis frame 101, a console 102, a vegetable receiving box 103, a vegetable washing water tank 104, a binding box 105 and a seat 106. The console 102, the vegetable receiving box 103, the vegetable washing water tank 104, the binding box 105 and the seat 106 are installed on the chassis frame 101, preferably, the console 102 is arranged on the right side of the conveying lifting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com