Assembly process of electric toothbrush

An assembly process, a technology of electric toothbrushes, applied in dentistry, cleaning teeth, medical science and other directions, can solve the problems of reducing the service life of the brush head, the distance of expansion is not the same, and the assembly is not firm, so as to increase the friction coefficient and make the connection firm. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

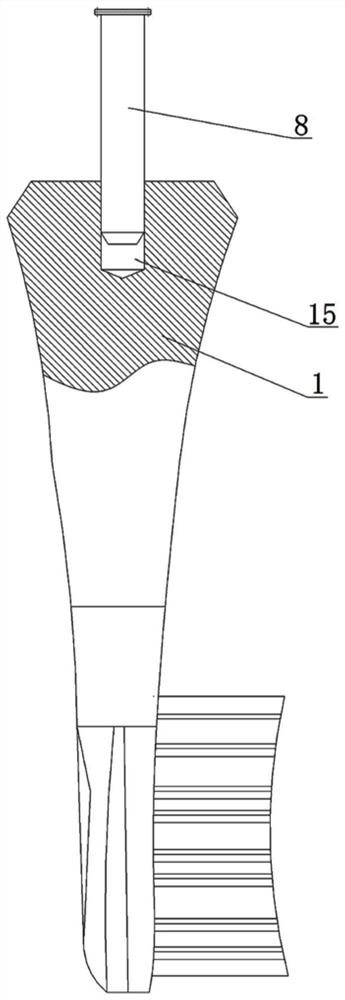

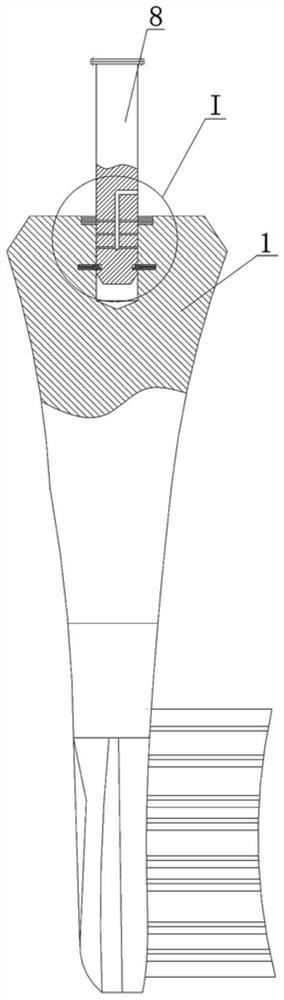

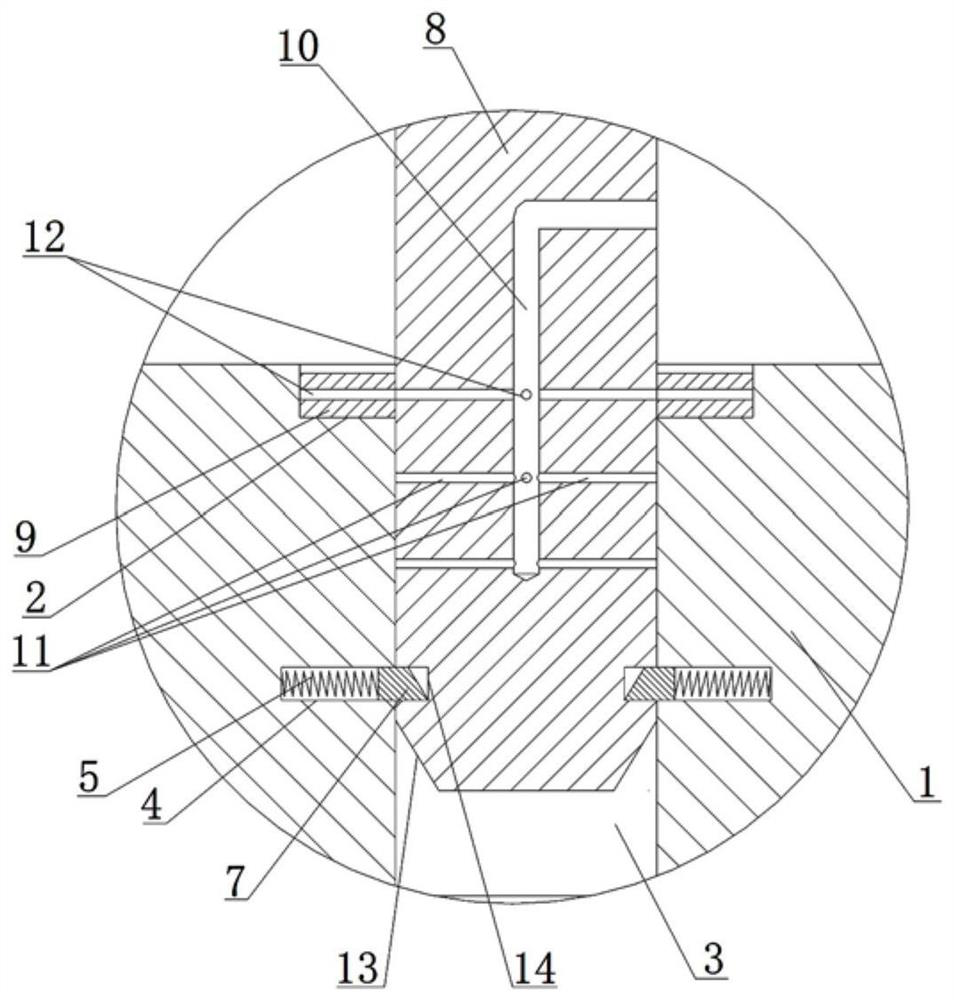

[0044] Embodiment one: if Figure 2~6 Shown, a kind of assembly process of electric toothbrush, it comprises the following steps:

[0045] S1, the processing of the brush head, its specific processing steps are:

[0046] S11, milling a square groove 2 on the top of the brush head 1, and machining a square blind groove 3 coaxial with the square groove 2 on the top of the square groove 2;

[0047] S12, using a sandblasting machine to perform sandblasting on the bottom surface and the inner surface of the square groove 2, to form a plurality of micropores on the bottom surface and the inner surface of the square groove 2, the diameter of the micropores is 0.03mm;

[0048] S13. A radial groove A4 is processed on the four sides of the square blind groove 3, a spring 5 is welded in each radial groove A4 and on the bottom of the groove, and a wedge-shaped spring 5 is slidably installed in each radial groove A4. The wedge-shaped block 7 facing 6 upwards, the wedge-shaped surface of ...

Embodiment 2

[0066] Such as Figure 2~6 Shown, a kind of assembly process of electric toothbrush, it comprises the following steps:

[0067] S1, the processing of the brush head, its specific processing steps are:

[0068] S11, milling a square groove 2 on the top of the brush head 1, and machining a square blind groove 3 coaxial with the square groove 2 on the top of the square groove 2;

[0069] S12, using a sandblasting machine to perform sandblasting on the bottom surface and the inner surface of the square groove 2, to form a plurality of micropores on the bottom surface and the inner surface of the square groove 2, the diameter of the micropores is 0.02mm;

[0070] S13. A radial groove A4 is processed on the four sides of the square blind groove 3, a spring 5 is welded in each radial groove A4 and on the bottom of the groove, and a wedge-shaped spring 5 is slidably installed in each radial groove A4. The wedge-shaped block 7 facing 6 upwards, the wedge-shaped surface of the wedge-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com