Circuit board cleaning device for instrument production

A technology for cleaning devices and circuit boards, which is applied to printed circuits, printed circuit manufacturing, chemical instruments and methods, etc. It can solve the problems of lack of positioning methods, unsafe cleaning of circuit boards, and slow drying speed, so as to improve safety , Stable positioning, and the effect of slowing down the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

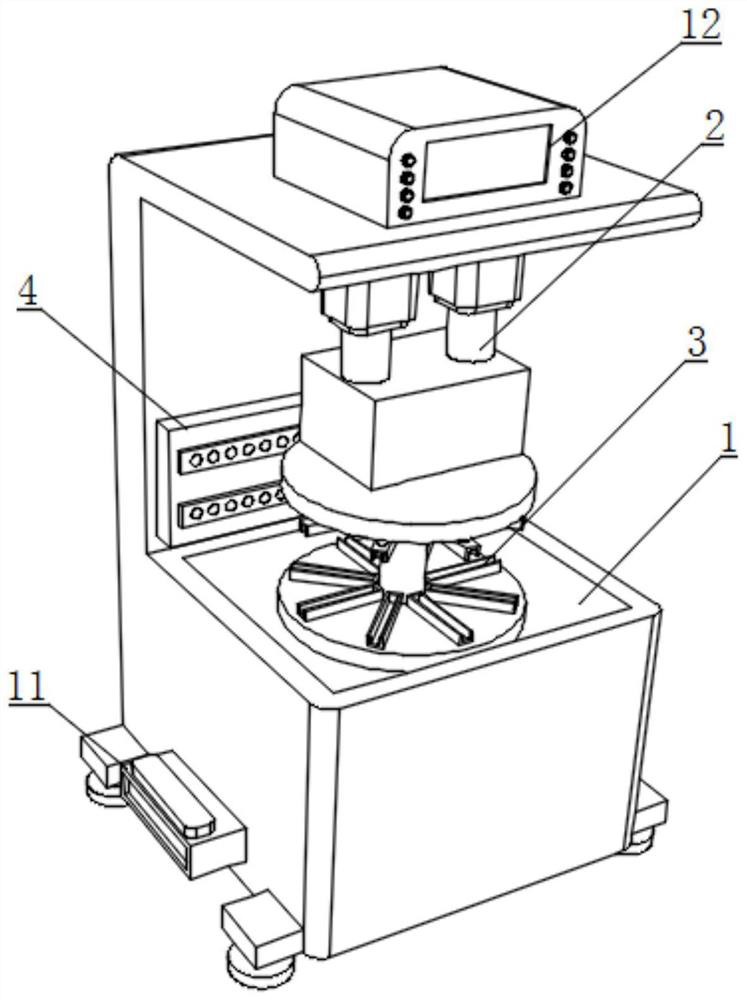

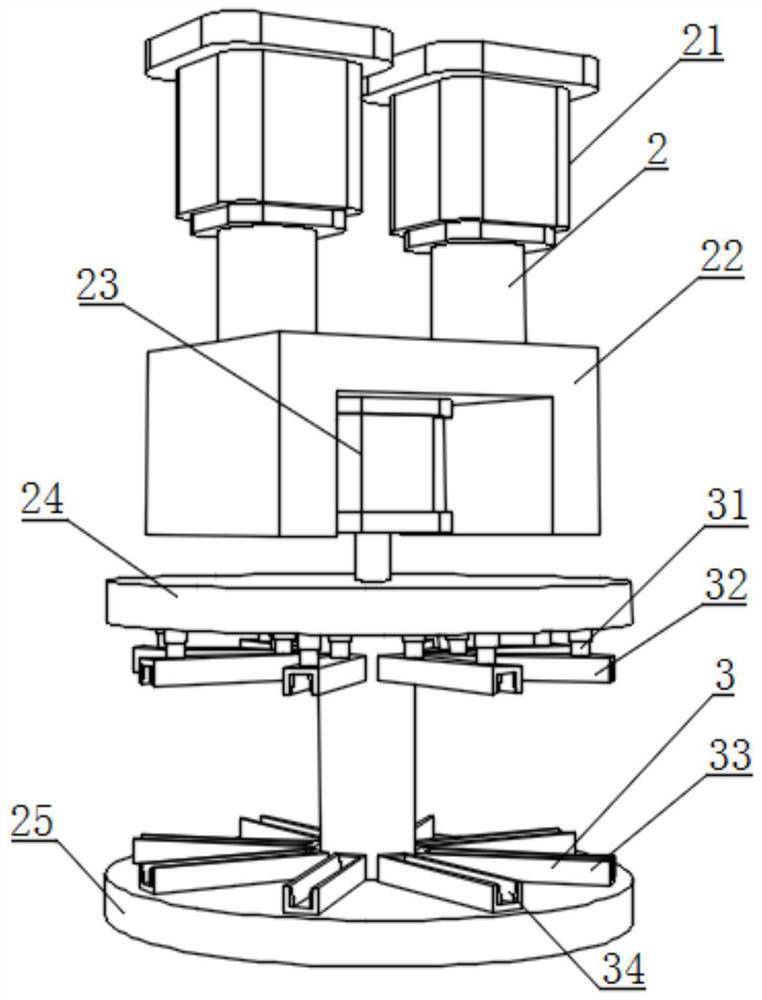

[0036] Such as Figure 1-6 As shown, the present invention provides a cleaning device for circuit boards used in the production of instruments and instruments, including a cleaning device main body 1, a control device 12 is fixedly installed on the top of the cleaning device main body 1, and a drain is fixedly installed on the left bottom of the cleaning device main body 1. Pipe 11, the inside of the cleaning device main body 1 is filled with cleaning liquid, the top of the inner wall of the cleaning device main body 1 is fixedly installed with a lifting mechanism 2, the bottom of the lifting mechanism 2 is provided with a positioning mechanism 3, and the rear of the lifting mechanism 2 is provided with a cleaning device body. The inner wall of 1 is fixedly connected to the drying mechanism 4, and the lifting mechanism 2 includes a lifting device 21, a fixed box 22, a driving motor 23, an upper positioning plate 24 and a lower positioning plate 25, and the output shaft of the d...

Embodiment 2

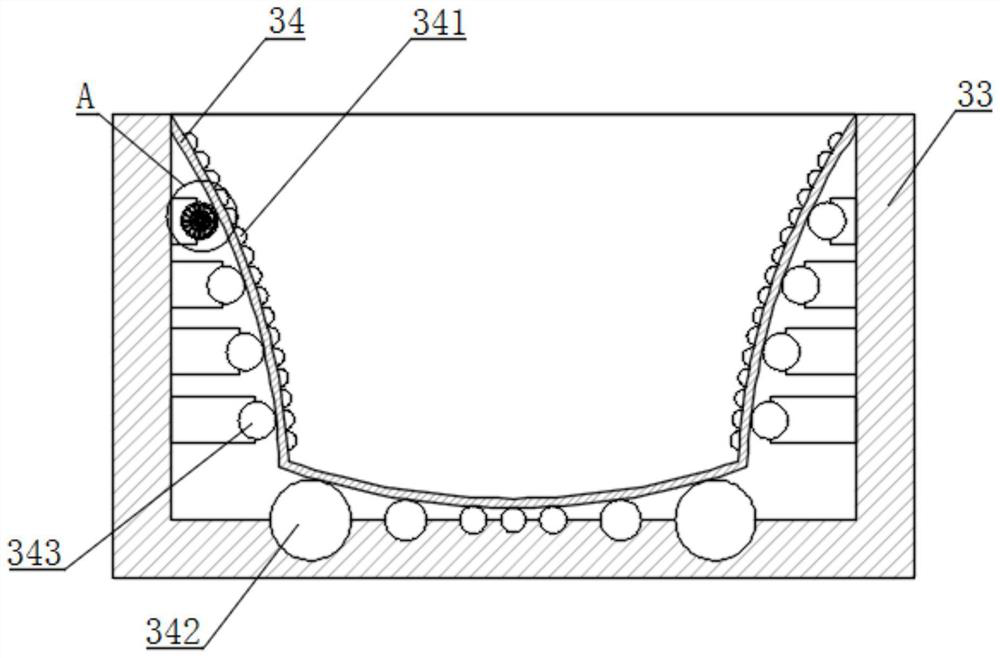

[0039] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the bottom surface of the telescopic device 31 is fixedly connected to the top of the upper positioning groove plate 32, and the bottom surface of the lower positioning groove plate 33 is connected to the lower positioning plate 25 The upper surface of the lower positioning slot plate 33 is evenly distributed on the upper surface of the lower positioning plate 25, the upper positioning slot plate 32 is arranged directly above the lower positioning slot plate 33, and the upper positioning slot plate 32 and the lower positioning slot plate 33 are aligned. One corresponding setting, the outer surface of the anti-compression limit rod 342 is fixedly connected with the inner cavity bottom of the lower positioning groove plate 33, and the outer surface of the soft protection pad 34 is fixedly equipped with rubber friction balls 341, and the rubber fricti...

Embodiment 3

[0041] Such as Figure 1-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: preferably, a connecting rod a2 is fixedly installed on the outer surface of the central axis a1, and one end of the connecting rod a2 is connected with the soft fixer The inner surface of 343 is fixedly connected, the inner wall of the connecting rod a2 is fixedly connected with the positioning clamp a3, the connecting rod a2 is arranged on the outer surface of the central axis a1 on the side away from the soft protection pad 34, and the outer surface of the central axis a1 There are flexible curved panels a4 fixedly connected, the number of flexible curved panels a4 is several, the flexible curved panels a4 are equally spaced on the outer surface of the central axis a1, one end of the adjacent flexible curved panel a4 is fixedly connected with an elastic plate a5, and the flexible curved panels a4 are fixedly connected to each other. The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com