Stem sliver processing system for tobacco industry

A treatment system and industry technology, applied in chemical/physical processes, solid waste removal, mixers, etc., can solve problems affecting the market operation of the tobacco industry, stems that cannot be handled at will or shipped outside, and no stems processing methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

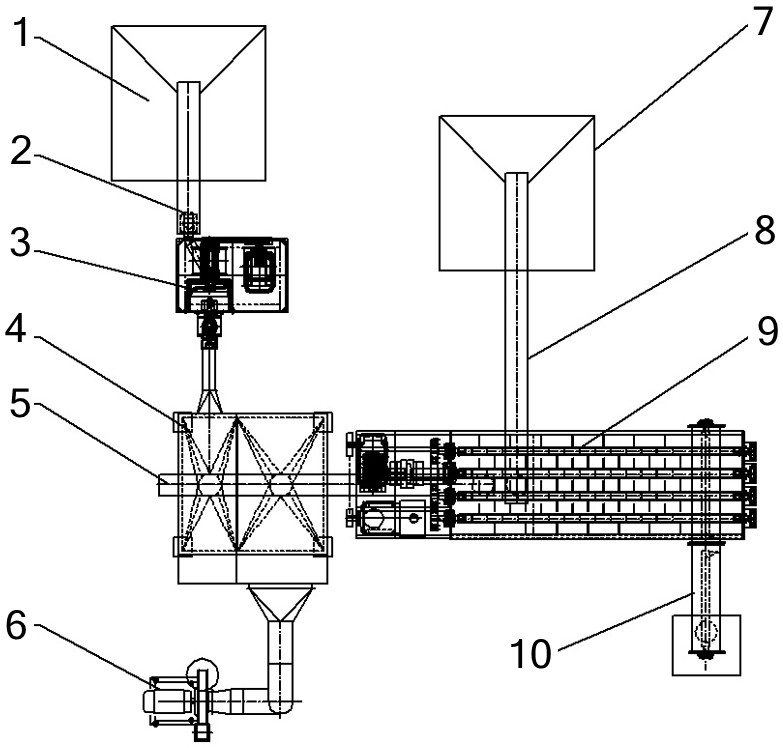

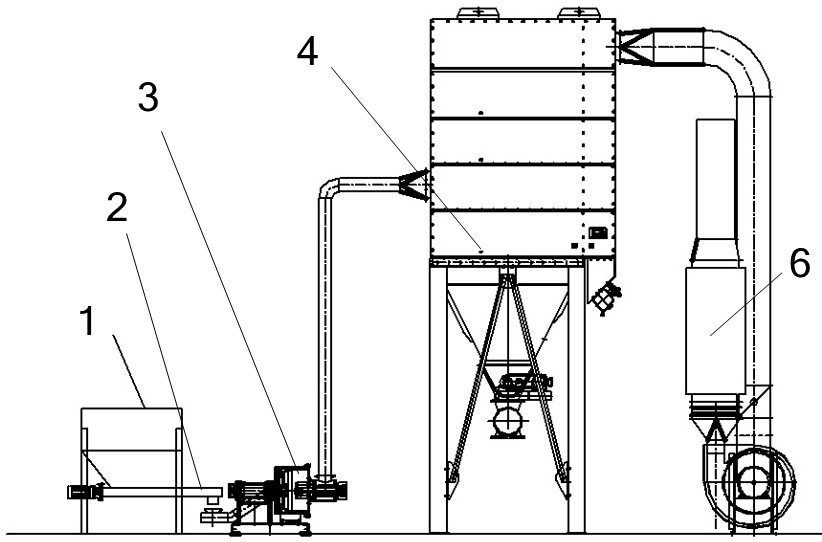

[0016] Such as Figure 1 to Figure 5 The shown is a stem label processing system for the tobacco industry, which is characterized in that it includes a stem label buffer warehouse 1, a screw conveyor I2, a pulverizer 3, a dust collector 4, a screw conveyor II5, a fan 6, and humic acid Buffer warehouse 7, screw conveyor III 8, mixing mixer 9 and screw conveyor IV 10, the stem stick buffer warehouse 1 is connected to the pulverizer 3 through the screw conveyor I2, the pulverizer 3 is connected to the dust collector 4, and the dust collector 4 is conveyed by a screw The machine II5 is connected to the mixer 9, the humic acid buffer bin 7 is connected to the mixer 9 through the screw conveyor III8, the mixer 9 is connected to the screw conveyor IV10, and the stem tags collected in the stem buffer bin 1 are conveyed through the screw conveyor I2 To the pulverizer 3, the stem sticks are crushed by the pulverizer 3, and collected to the ash hopper of the dust collector 4, and the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com