Positive electrode surface modification material and preparation method thereof

A technology of surface modification and positive electrode materials, applied in the direction of positive electrodes, electrode manufacturing, battery electrodes, etc., can solve the problems of increased charge transfer resistance, low lithium ion conductivity, and affecting material rate performance, so as to achieve accelerated transfer and deposition The effect of low difficulty and improved cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The second aspect of the present invention provides the preparation method of the positive electrode surface modification material described in the first aspect of the present invention, comprising:

[0047] 1) Coating the surface of the positive electrode material to obtain a chemically inert layer;

[0048] 2) Annealing the chemically inert layer in step 1) to obtain a positive electrode surface modification material having both a doped layer and a coating layer.

[0049] In the preparation method of the positive electrode surface modification material provided by the present invention, the step 1) is to coat the surface of the positive electrode material to obtain a chemically inert layer. Specifically for this application, the coating method may be, for example, an atomic layer deposition method. Atomic layer deposition (ALD) is an advanced cladding technique that enables the deposition of uniform conformal thin films on high surface area and complex shaped substra...

Embodiment 1

[0077] 1. Preparation of cathode surface modification materials

[0078] 1) The atomic layer deposition coating of the chemically inert layer can be realized by T-ALD-100Asystem (KE-MICRO) and Yunmao GT10 powder ALD system atomic layer deposition equipment.

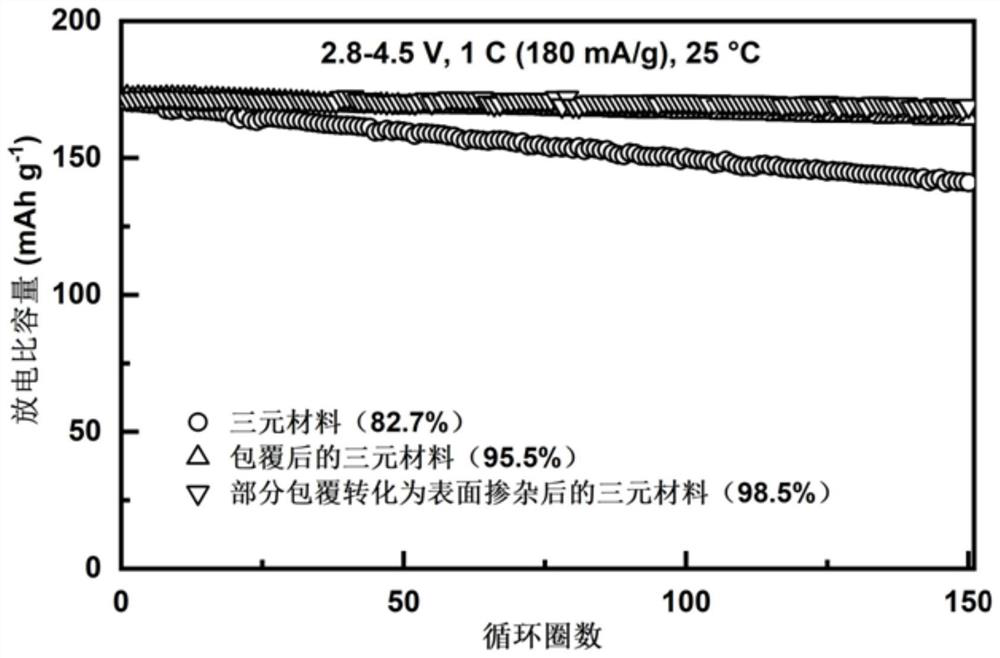

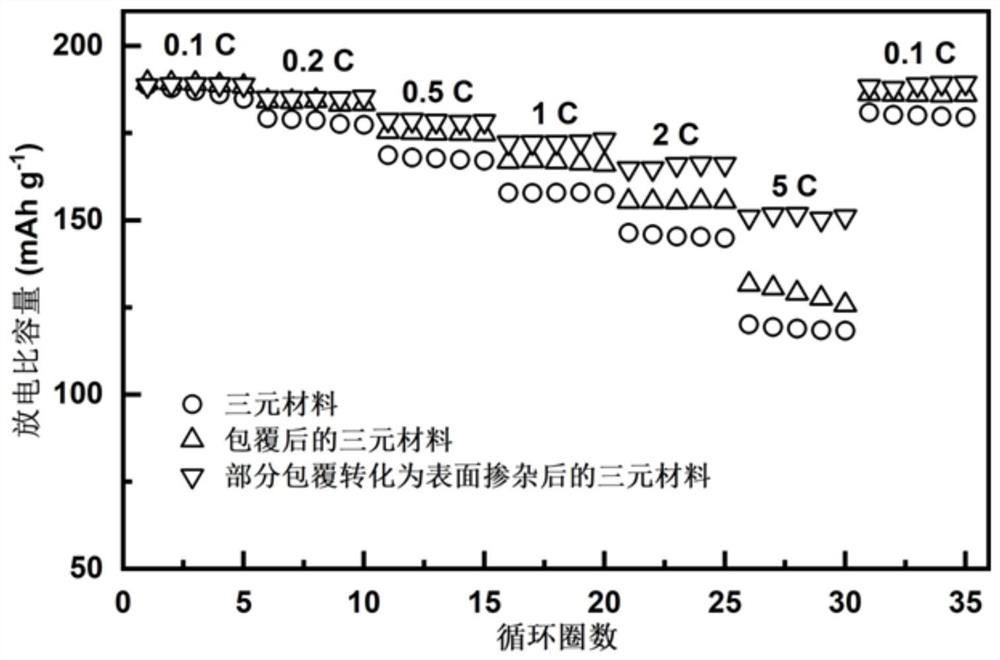

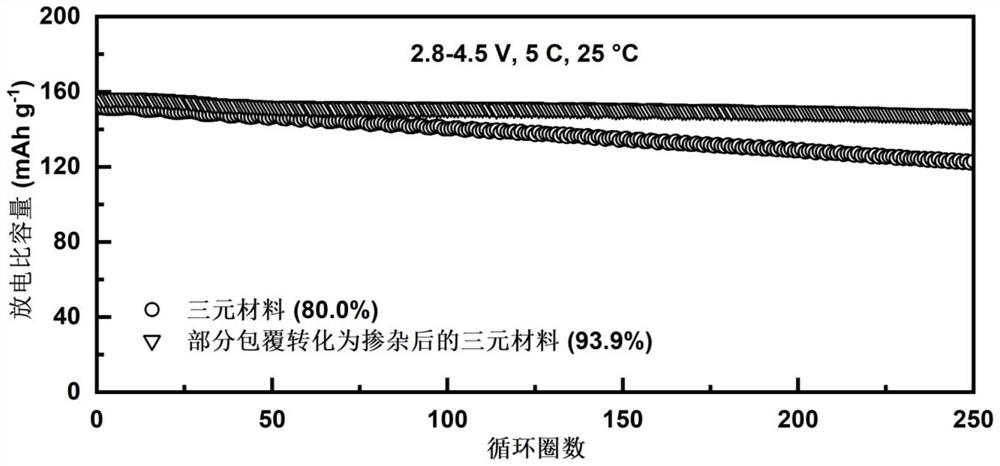

[0079] The ternary material LiNi 0.6 co 0.2 mn 0.2 o 2 Place the powder or electrode in the sample barrel to preheat 150°C and mechanically stir or vibrate for 30 minutes at the same time, and then alternately pass through the chemical precursor source (tetradimethylamino zirconium and deionized water) for one or more Alternate deposition of thin films, zirconium tetradimethylamide and deionized water will react to form zirconia. By controlling the number of atomic layer deposition circles to be 5, the nanoscale thickness precision control of the chemically inert layer can be realized. The obtained surface-modified chemically inert layer has a thickness of 1.2nm and accounts for 0.13% by mass of the positive electrod...

Embodiment 2

[0094] The chemically inert layer (initial cladding layer) is 1.2nm. Compared with Example 1, the difference is that the annealing temperature is reduced to 300° C., the doping / coating ratio of the final product is reduced, and the chemically inert layer (initial cladding layer) 25% of the metal elements in the layer) enter the ternary material to form a doped layer, and the doping elements in the doped layer account for 5.7% by mass of the doped layer. The average thickness of the remaining cladding layer after annealing was 0.9 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com