Solar power generation equipment with cleaning function

A technology for solar power generation panels and power generation equipment, applied in the field of solar power generation, can solve the problems of inability to receive sunlight, affect service life, decrease power generation efficiency, etc., and achieve the effects of smooth pressing process, prolong service life, and improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

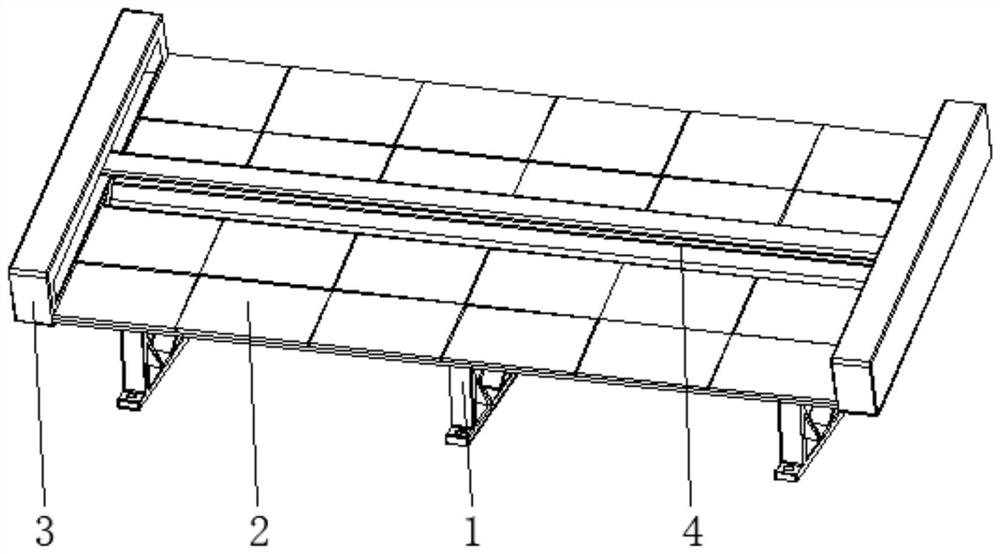

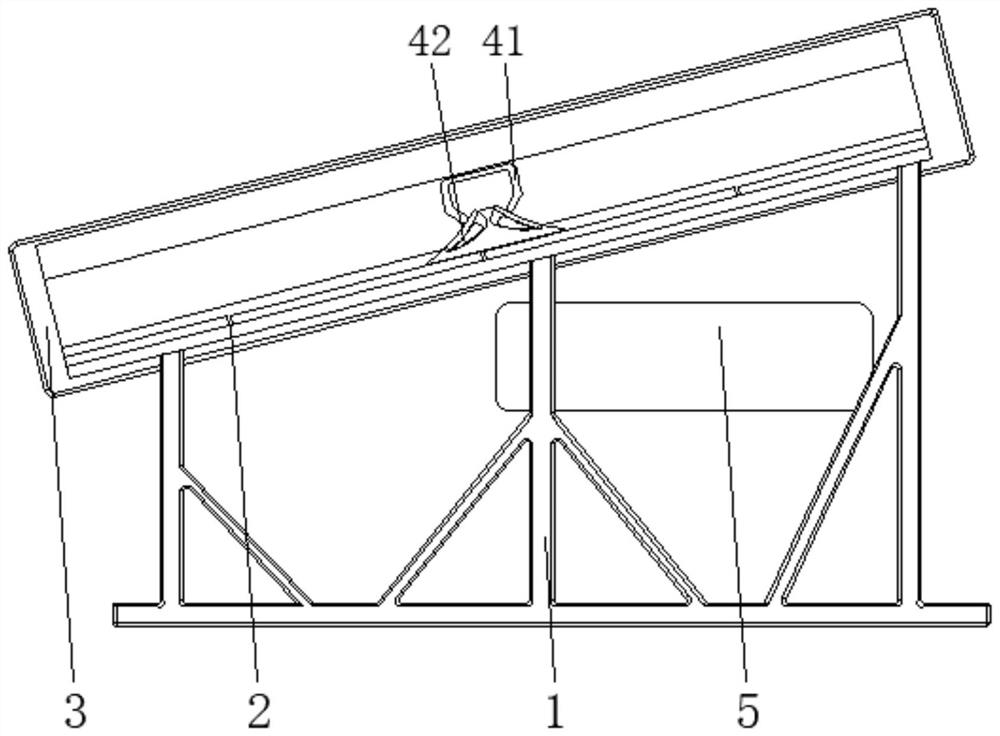

[0029] see Figure 1-6 , the present invention provides a technical solution: a solar power generation device with a cleaning function, including a bracket 1, a solar power generation panel 2, a power drive device 3, an integrated processing device 4, a processing box 5, the bottom of the solar power generation panel 2 and the bracket The top of 1 is fixedly connected, the power drive device 3 is arranged on both sides corresponding to the surface edge of the solar power generation panel 2, the integrated processing device 4 is arranged on the top of the solar power generation panel 2, and the end of the integrated processing device 4 is connected to the power drive device 3 Fitting connection between them, the processing box 5 is fixed on the surface of the support 1 and is close to the position of the solar power generation panel 2;

[0030] The integrated processing device 4 is provided with a bar-shaped pressing device 41 and a cleaning device 42. The bar-shaped pressing d...

Embodiment example 2

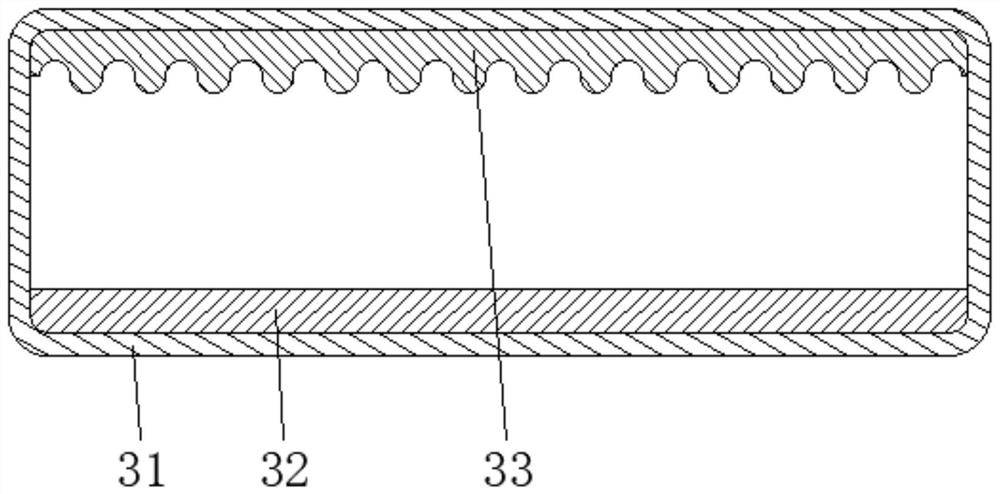

[0032] The power drive device 3 is provided with a casing 31, a linear motor 32, and a sawtooth pressure plate 33. One side of the surface of the casing 31 is fixedly connected to the surface edge of the solar power generation panel 2. The linear motor 32 is arranged at the bottom of the inner wall of the casing 31 and is connected with the cleaning device 42. , the sawtooth pressing plate 33 is fixed on the top of the inner wall of the casing 31 and is connected with the strip pressing device 41 in cooperation.

[0033] The bar-shaped pressing device 41 is provided with a bar-shaped gland 411, a protrusion 412, and a ball 413. The end of the bar-shaped gland 411 is slidably connected with the power drive device 3, and the protrusion 412 is fixed on the top of the bar-shaped gland 411. And close to the end position, the ball 413 is arranged at the bottom of the strip gland 411. Driven by the linear motor 32, when the housing 31 moves together with the scraper base 421, and the ...

Embodiment example 3

[0035]The cleaning device 42 is provided with a scraper substrate 421, an arc-shaped pressing plate 422, an air bag 423, an arc-shaped elastic member 424, an air injection hole 425, and a wiping device 426. The scraper substrate 421 is arranged at the bottom of the strip-shaped pressing device 41 and is located 2, the arc-shaped pressing plate 422 is rotatably connected to the two sides corresponding to the surface of the scraper base 421, the airbag 423 is arranged between the bottom of the arc-shaped elastic member 424 and the corresponding two sides inside the scraper base 421, and the arc-shaped elastic The part 424 is arranged between the bottom of the arc-shaped elastic part 424 and the two sides corresponding to the inside of the scraper base 421 and close to the position of the air bag 423. Connected, the wiping device 426 is arranged inside the scraper base 421 and close to the arc-shaped elastic member 424. When the scraper base 421 moves, the dust, rain and snow on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com