Novel book back processing technology of perfect binding machine

A processing technology and technology of glue binding machine, applied in the field of book back processing technology of glue binding machine, can solve the problems of thickening of book backs, inability to discharge, affecting the quality of gluing, etc., and achieve the effect of improving the firmness of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

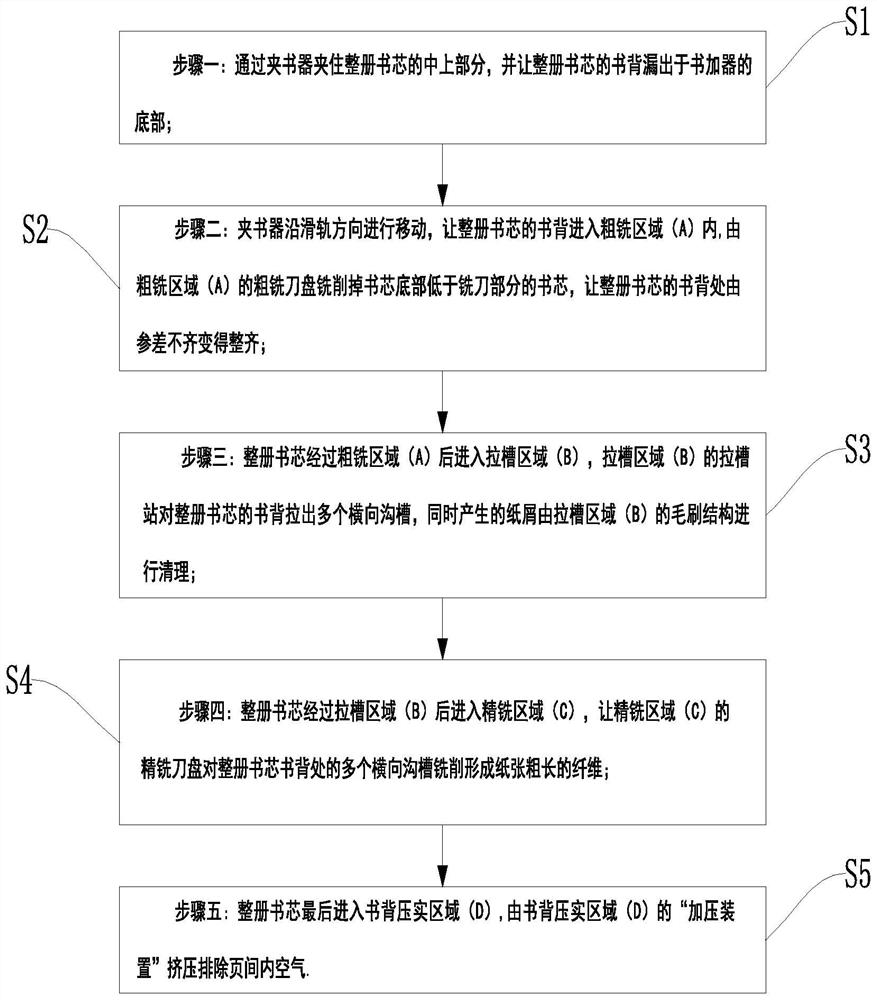

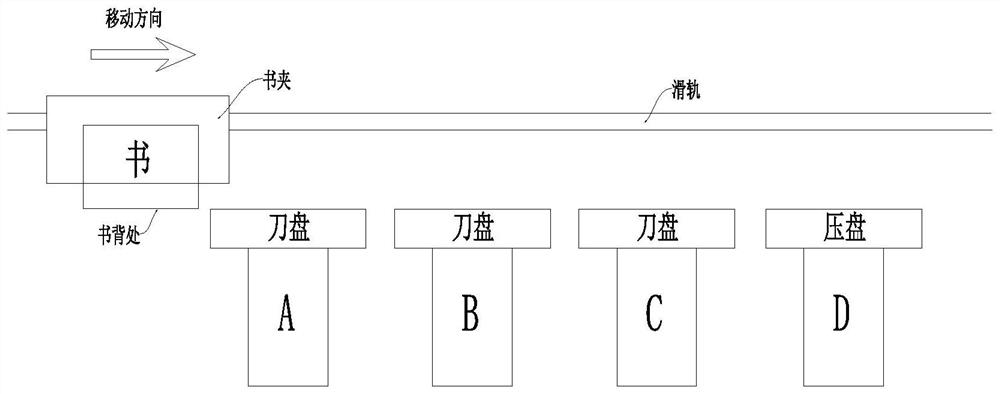

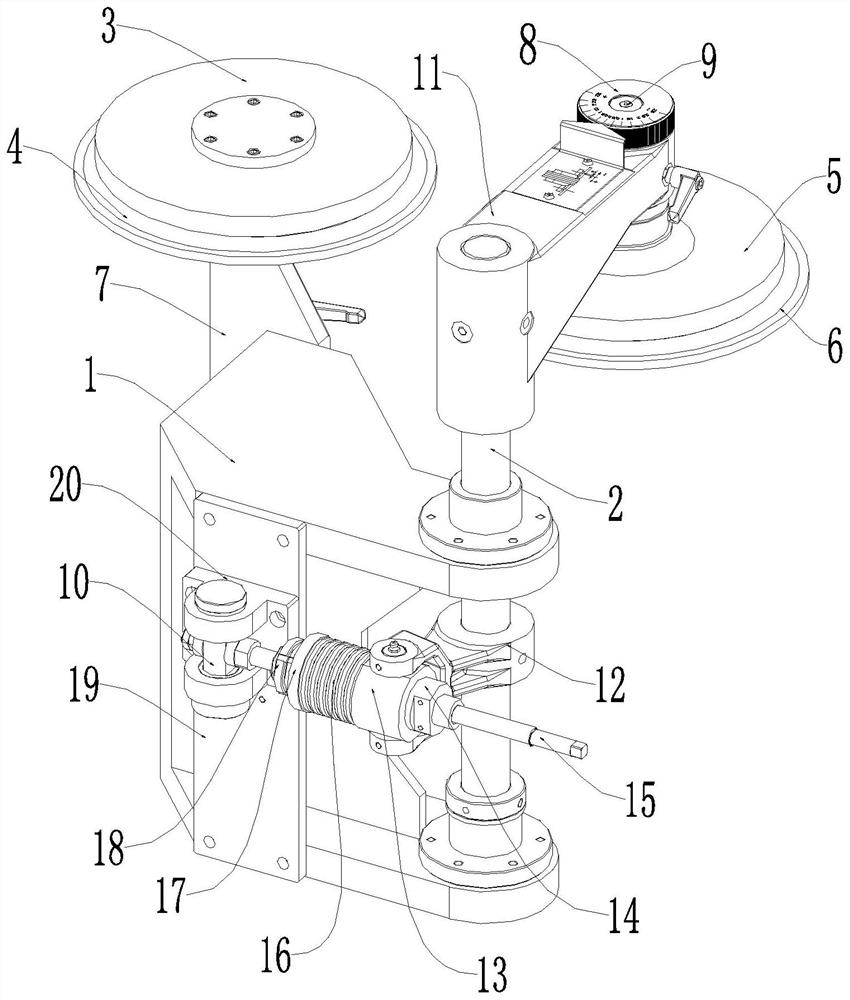

[0032] Example: such as figure 1 and figure 2 Shown, a kind of novel perfect binding machine book back processing technology of the present invention comprises the following steps:

[0033] Step 1: Clamp the middle and upper part of the whole book block with the book clamp, and let the back of the whole book block leak out from the bottom of the book clamp; drive to move.

[0034] Step 2: The book holder moves along the direction of the slide rail, so that the back of the entire book block enters the rough milling area A, and the rough milling cutter disc in the rough milling area A mills off the book block at the bottom of the book block that is lower than the milling cutter , so that the back of the entire book block changes from uneven to neat; the driving device drives the rough milling cutter to rotate and perform rough milling work on the back of the book block at the top to remove the irregular part of the back of the book;

[0035] Step 3: The whole book block ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com