Liquid carbon dioxide and water vapor anti-reflection coal gas displacement device and method

A technology of liquid carbon dioxide and water vapor, applied in the direction of gas discharge, safety devices, mining fluids, etc., can solve the problems that cannot reflect the actual situation on site, cannot immediately carry out gas drainage, reduce the efficiency of gas drainage, etc., and achieve improved gas drainage Mining efficiency, simple structure, and the effect of strengthening the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

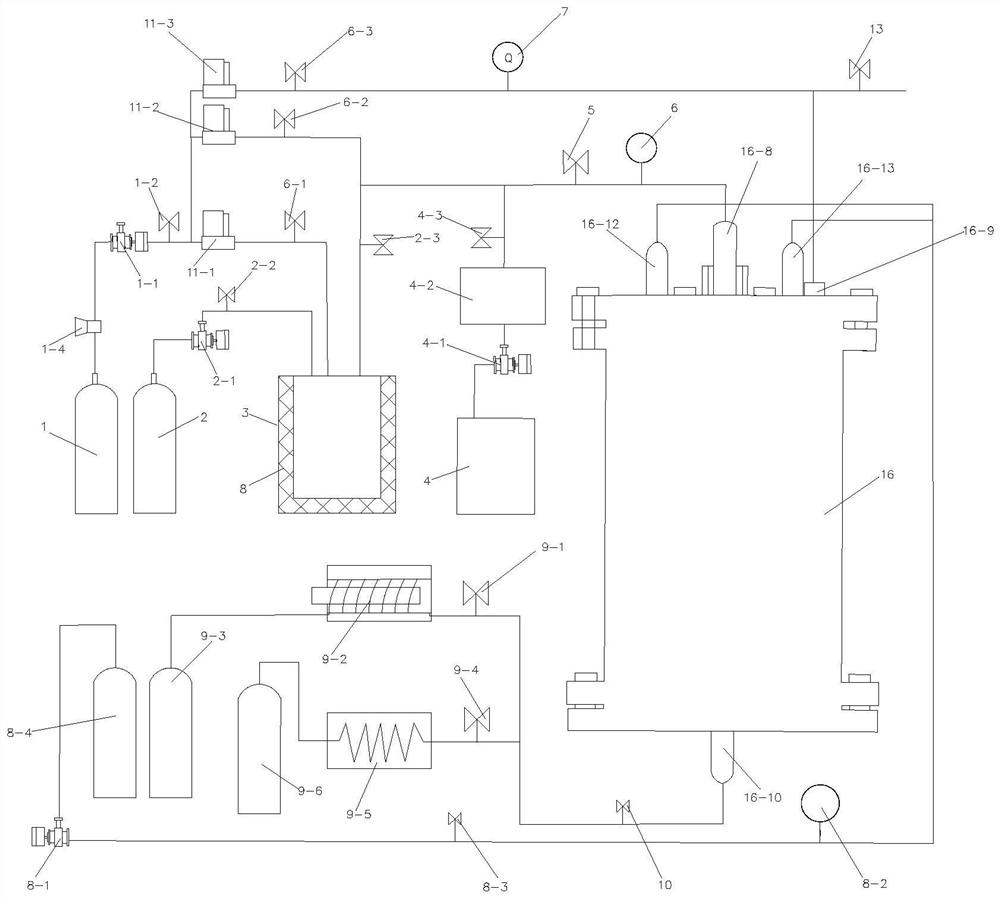

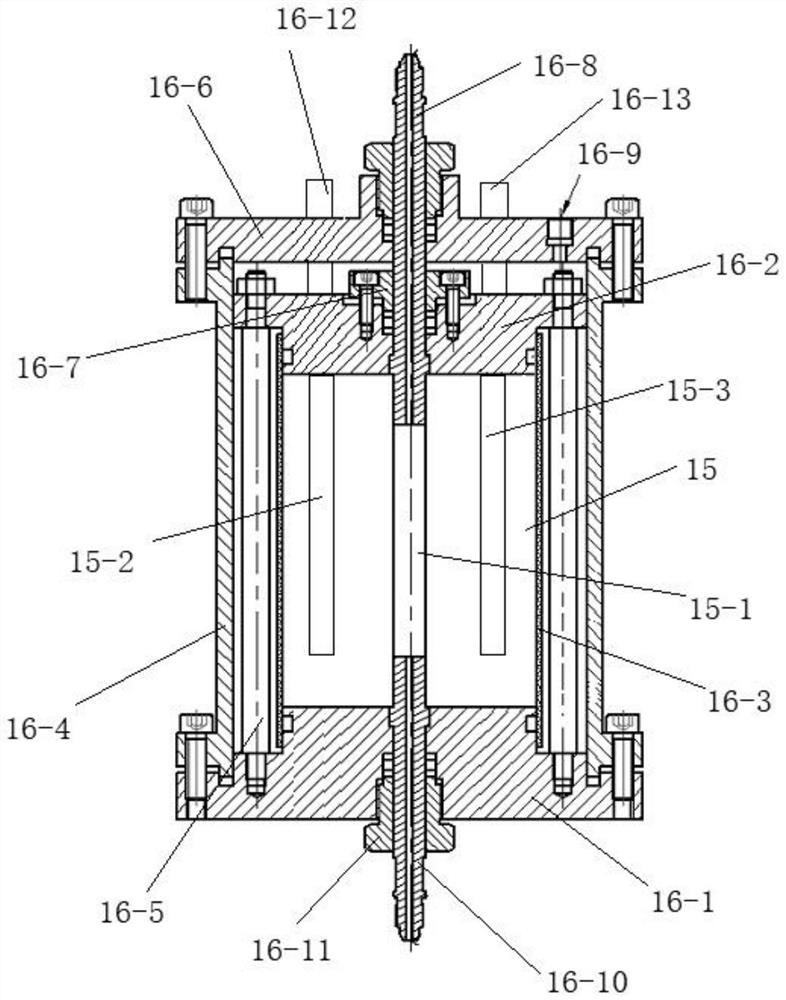

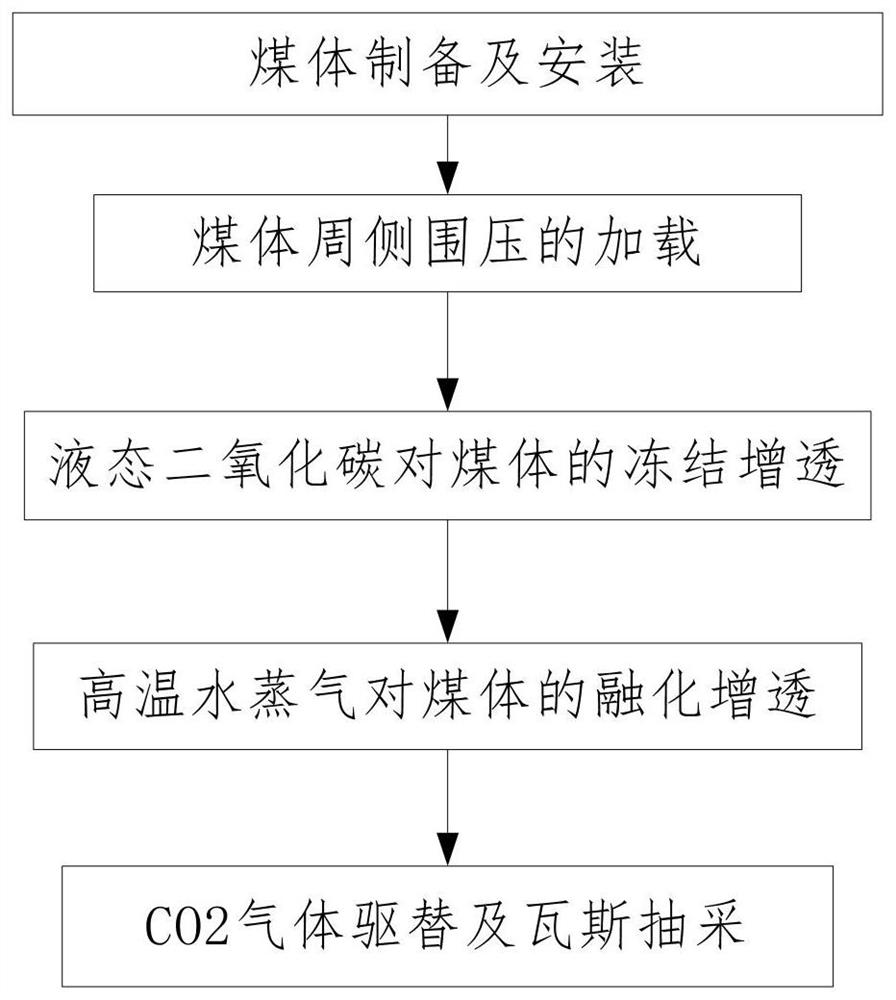

[0088] Such as Figure 1 to Figure 2 A liquid carbon dioxide and water vapor anti-permeability coal gas displacement device shown includes a liquid CO2 anti-permeability mechanism, a high-temperature water vapor mechanism, and a reactor 16 for placing the coal body, as well as a CO2 connected to the reactor 16. A collection mechanism, a water vapor collection mechanism, and a drainage mechanism, the reactor 16 is connected with a CO2 displacement replacement component and a confining pressure loading component;

[0089] The liquid CO2 anti-reflection mechanism includes a liquid CO2 tank 2, a liquid CO2 delivery pump 2-1, a liquid CO2 valve 2-2 and a liquid CO2 tank 3 connected in sequence, and a CO2 gas loading component is connected to the liquid CO2 tank 3, The CO2 displacement replacement part, the confining pressure loading part and the CO2 gas loading part are all connected to the gaseous CO2 mechanism, the liquid CO2 valve 2-2 is located on the liquid CO2 pipeline, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com