Liquid deslagging cyclone furnace with three-section type secondary air control valve

A technology of liquid slag discharge and secondary air, applied in the direction of adjusting air supply, non-flammable liquid/gas transportation, and combustion control, etc., can solve problems such as increased carbon content in boilers, clogging of slag outlet, and inability to discharge ash and slag. , to achieve the effect of smooth slag discharge, sufficient mixing and combustion, and increase the combustion temperature of the cyclone furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

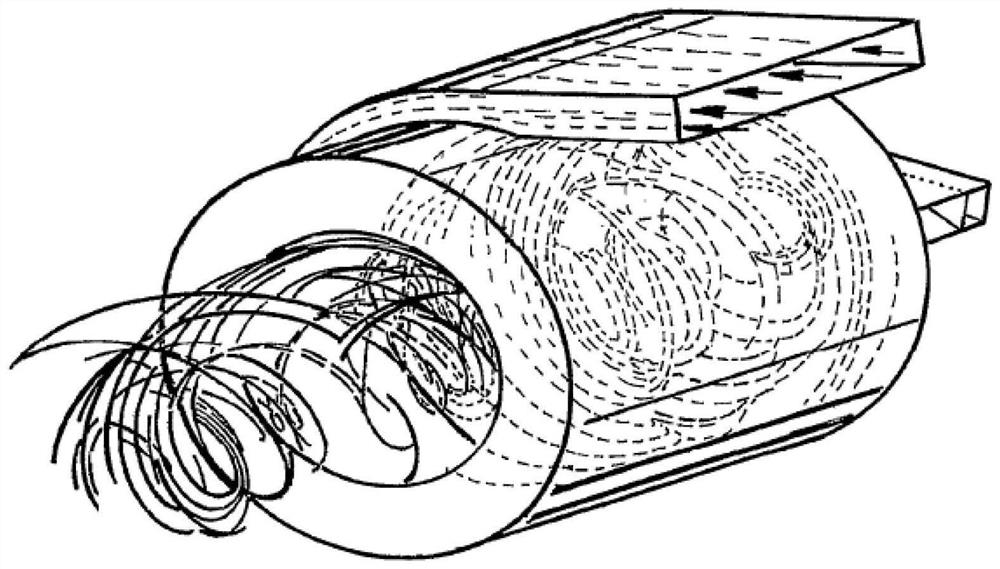

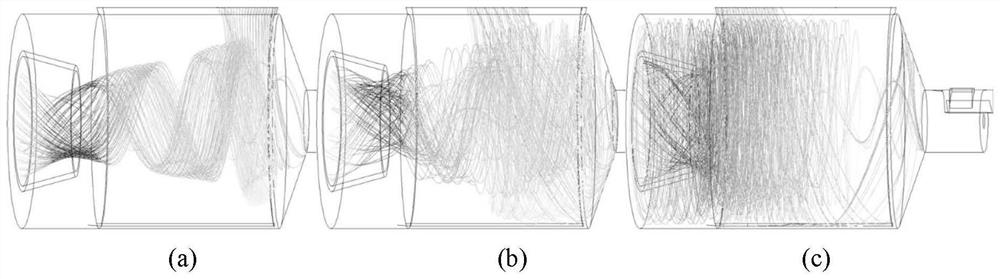

Method used

Image

Examples

Embodiment 1

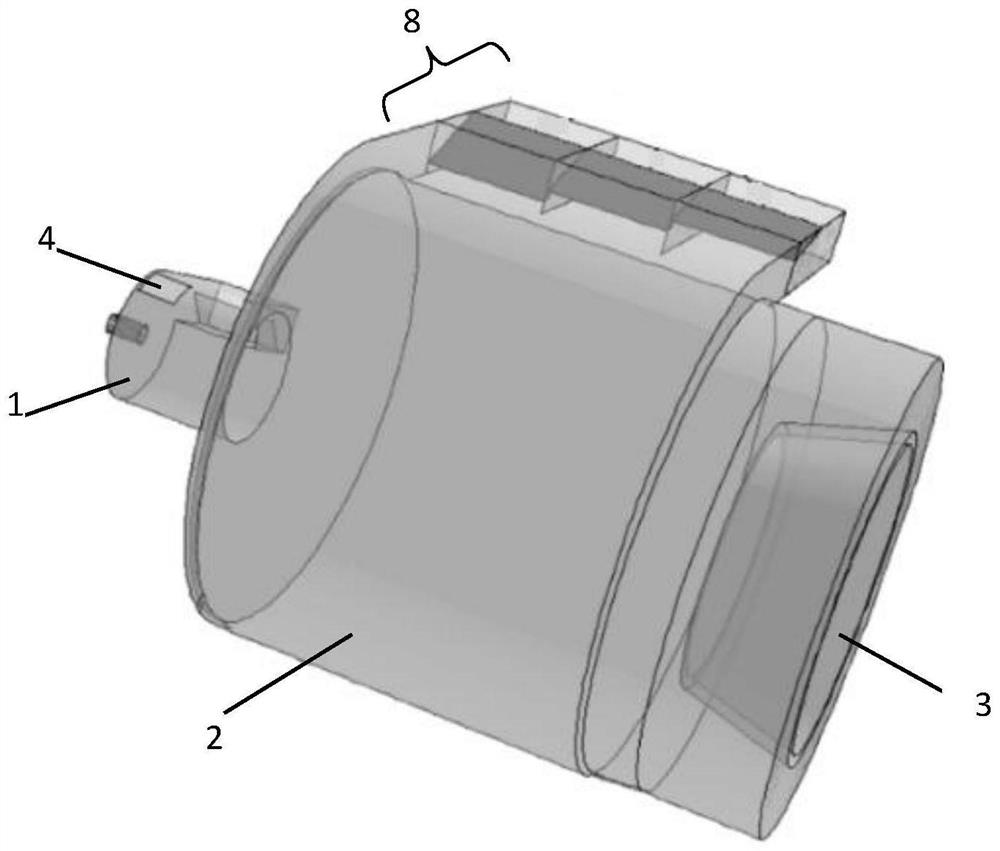

[0033] Such as image 3 , Figure 4a-4b As shown, a liquid slag discharge cyclone furnace with a three-stage secondary air regulating door, including a cyclone 2, a burner 1 arranged at the front end of the cyclone, and a cyclone furnace outlet 3 arranged at the end of the cyclone, the burner 1 is provided with a coal particle inlet 4 and a tertiary air inlet 7, and the coal particle inlet 4 is provided with a primary air channel, and the primary air channel includes a primary air inlet 5 and a primary air control door 51. The secondary air channel extends from the cyclone tube inlet to the top of the cyclone furnace along the outer wall of the cyclone furnace, and is set beyond the top of the cyclone furnace, and the area where the secondary air channel exceeds the top of the cyclone furnace is set as a wind regulating area 8. The end of the secondary air channel is the secondary air inlet 6, and the secondary air outlet is opposite to the secondary air inlet, that is, it is...

Embodiment 2

[0044] In this embodiment, the air duct partition is adjusted on the basis of embodiment 1. Only the differences from embodiment 1 will be described below, and the same parts will not be repeated.

[0045] Such as Figure 6 As shown, in order to make the rotating flow direction of the secondary air in the cyclone furnace more towards the furnace mouth, the partition 9 is arranged obliquely in the air regulating area, and the side of the partition away from the secondary air inlet faces the cyclone furnace outlet The direction is deflected by 10°; and the contours of the first secondary air regulating door, the second secondary air regulating door and the third secondary air regulating door are adapted to the first-third section, and the first-third second One end of the secondary air regulating door is fixed on the upper wall in the corresponding section, and the other ends of the first secondary air regulating door and the second secondary air regulating door extend obliquely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com