Manufacturing method of brick-steel composite assembly type self-standing steel chimney

A manufacturing method and self-supporting technology, which is applied in the direction of combustion methods, exhaust gas devices, lighting and heating equipment, etc., can solve the problems of complex construction methods, potential safety hazards, difficulty in ensuring construction quality, low efficiency of on-site implementation, etc., and shorten the construction period , reduce potential safety hazards, and promote development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

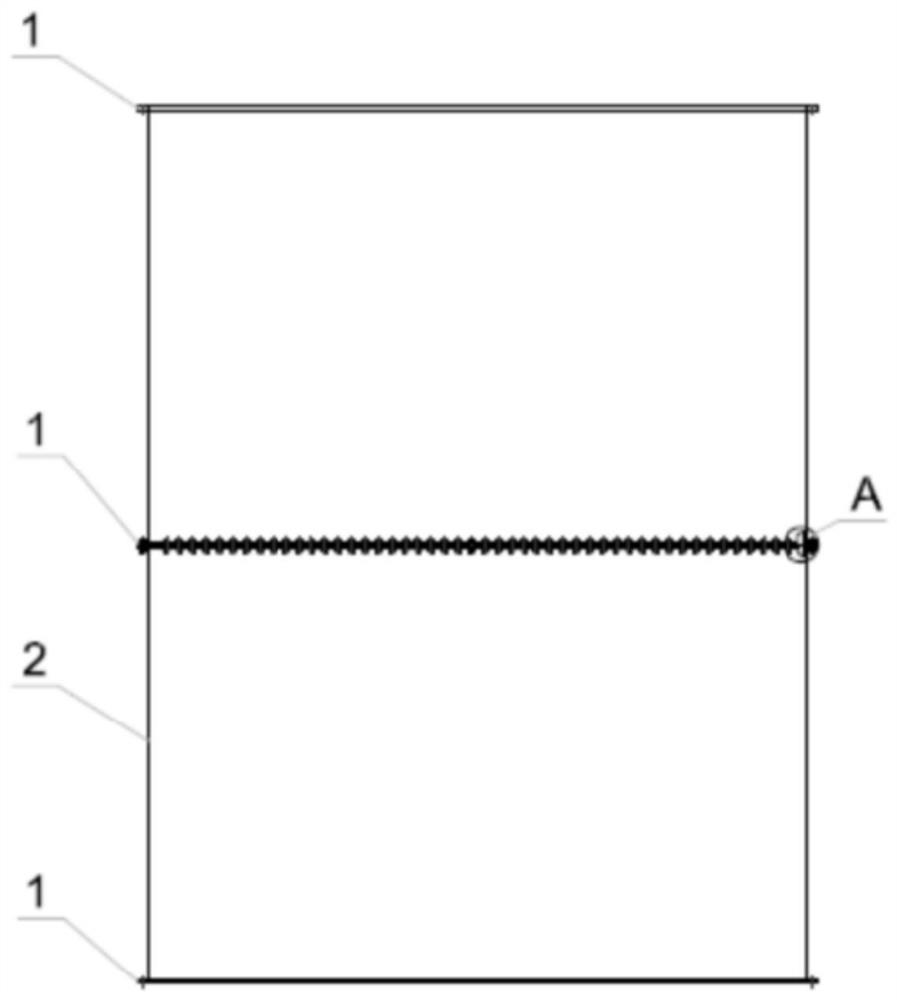

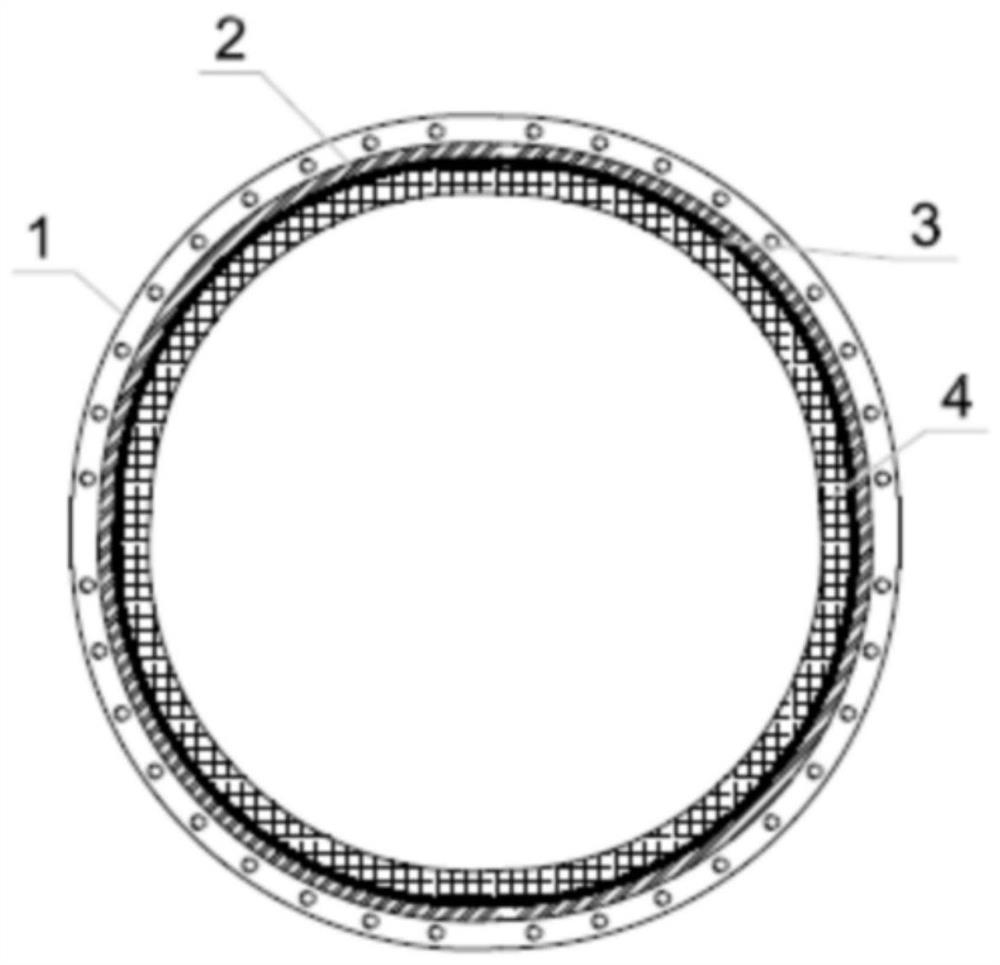

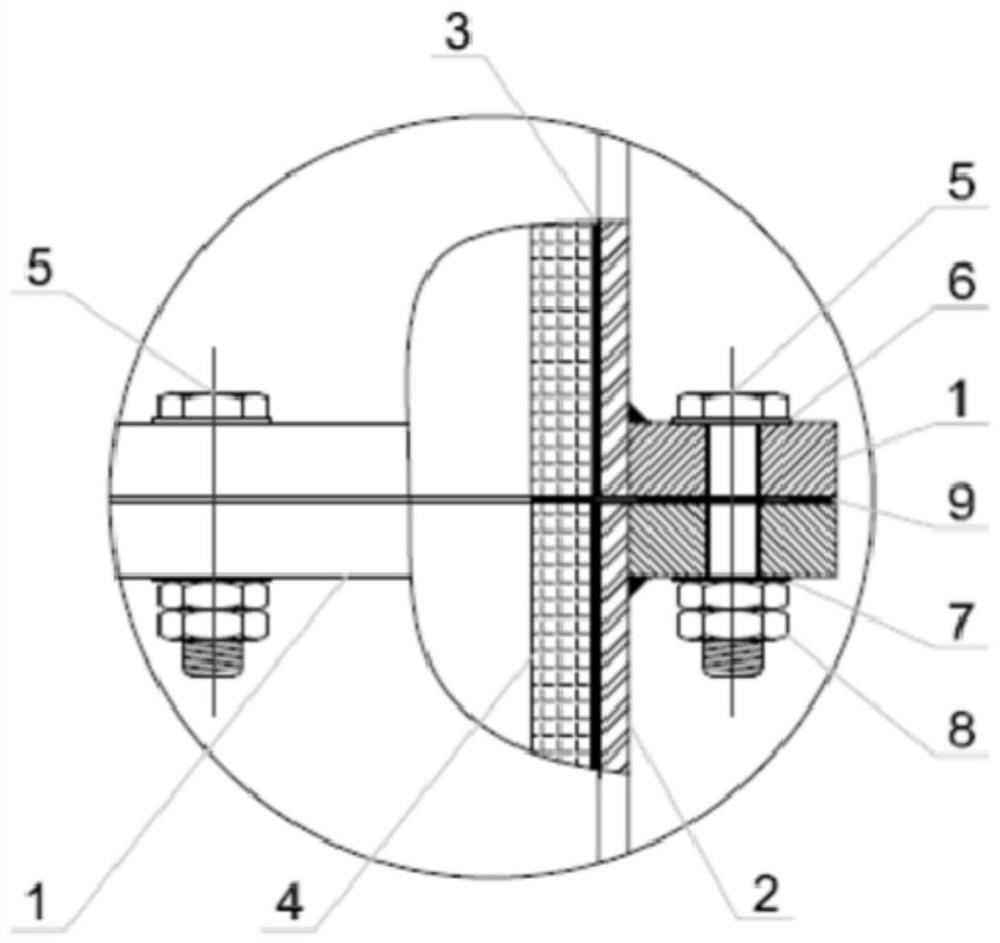

[0023] This embodiment provides a method for manufacturing a brick-steel composite assembly type self-supporting steel chimney, including manufacturing single-section reels and flanges of the steel chimney, cleaning and primer painting, brick-steel composite manufacturing, and on-site assembly installation; refer to Figure 1-3 , the specific process includes:

[0024] For steel chimneys with a diameter of less than 4m, first divide them into several cylindrical sections with a certain height (3-17m) according to the design (such as figure 1 ); respectively, the reel 2 is cut, the accessories and the circumferential flange 1 are made, and the matching welding is completed; the inner surface of the steel chimney wall 2 is cleaned and painted with a special high-temperature-resistant anti-corrosion primer; the inspection is completed on each cylindrical tube section After passing the test, borosilicate glass bricks 4 are pasted to form a brick-steel complex; finally, it is deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com