Cold state simulation method and device for coking process of heating surface of incinerator

A cold-state simulation and surface coking technology, which is applied in the intersecting fields of energy and environment, can solve the problems that the incinerator is difficult to observe and the incinerator is difficult to realize in the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

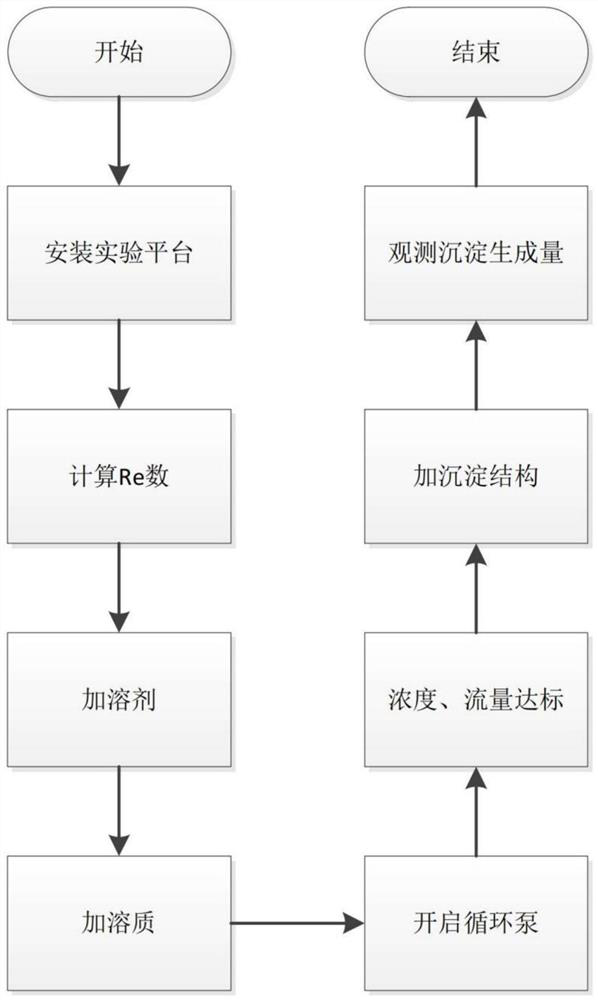

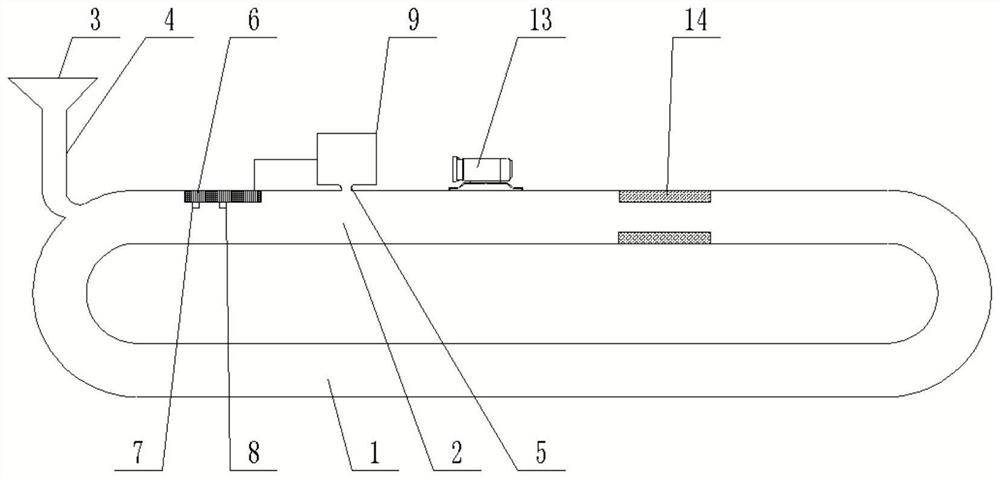

[0058] The cold state simulation of the coking process of the heating surface in the incinerator under the actual production situation, such as the flow diagram Figure 1 As shown, the experimental apparatus is as follows Figure 2-3 as shown.

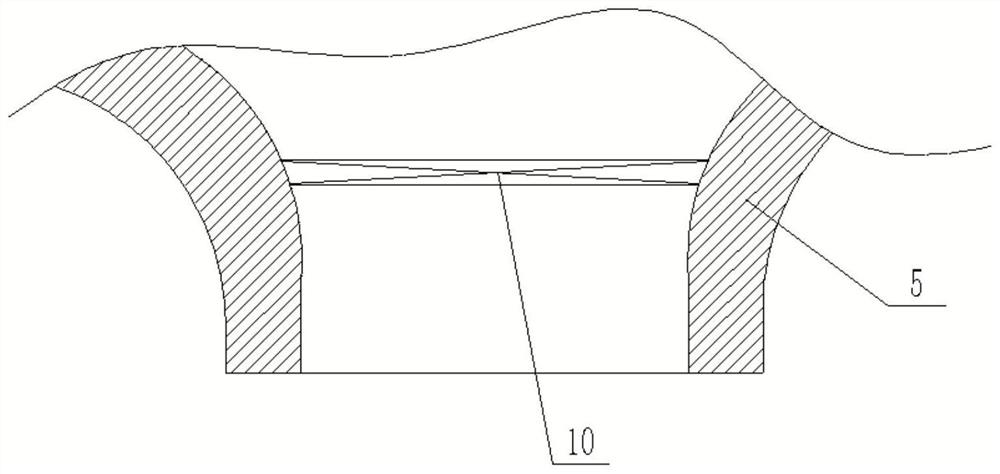

[0059] In the present embodiment, the circulation channel is a ring pipe structure having two main pipes 1, the main pipe 1 is a transparent cylindrical tube, and any one of the main pipes 1 is located at the top of the other main pipe 1, in fact, the circulation channel 1 uses a transparent cylindrical ring describer, which is a closed ring pipe, has good sealing and is convenient to observe the progress of the reaction.

[0060] The injection channel comprises the injection port 3, the injection port 3 is connected to the main pipe 1 through the first injection pipe 4 and is connected, the injection port 3 is a funnel-shaped structure, the injection port 3 and the first injection pipe 4 are higher than the circulation channel as a whole, ...

Embodiment 2

[0076] As in Example 1, the difference is that the reaction structure 14 is added to the reaction assembly in step (6) as a precipitate structure (Fe bar).

[0077] The results showed that during the cold simulation, the surface of the Fe rod was covered with a layer of red substance, and the solution changed from blue to light green.

Embodiment 3

[0079] With Example 1, the difference is that in step (3) a solute (AgNO) is added to the solvent 3 Step (6) Add reaction structure 14 as the precipitate structure (Cu rod) to the reaction assembly.

[0080] The results showed that during the cold simulation, the surface of the Cu sheet was covered with a layer of silvery-white substance, and the solution changed from colorless to blue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com