Full-automatic 5G filter cavity production device

A fully automated, production device technology, used in cooling fluid circulation devices, waveguide-type devices, household refrigeration devices, etc., can solve the problems of long cooling time, easy to reduce cavity production efficiency, etc., to improve production efficiency and improve processing speed. , the effect of accelerating the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The application will be described in further detail below in conjunction with the accompanying drawings.

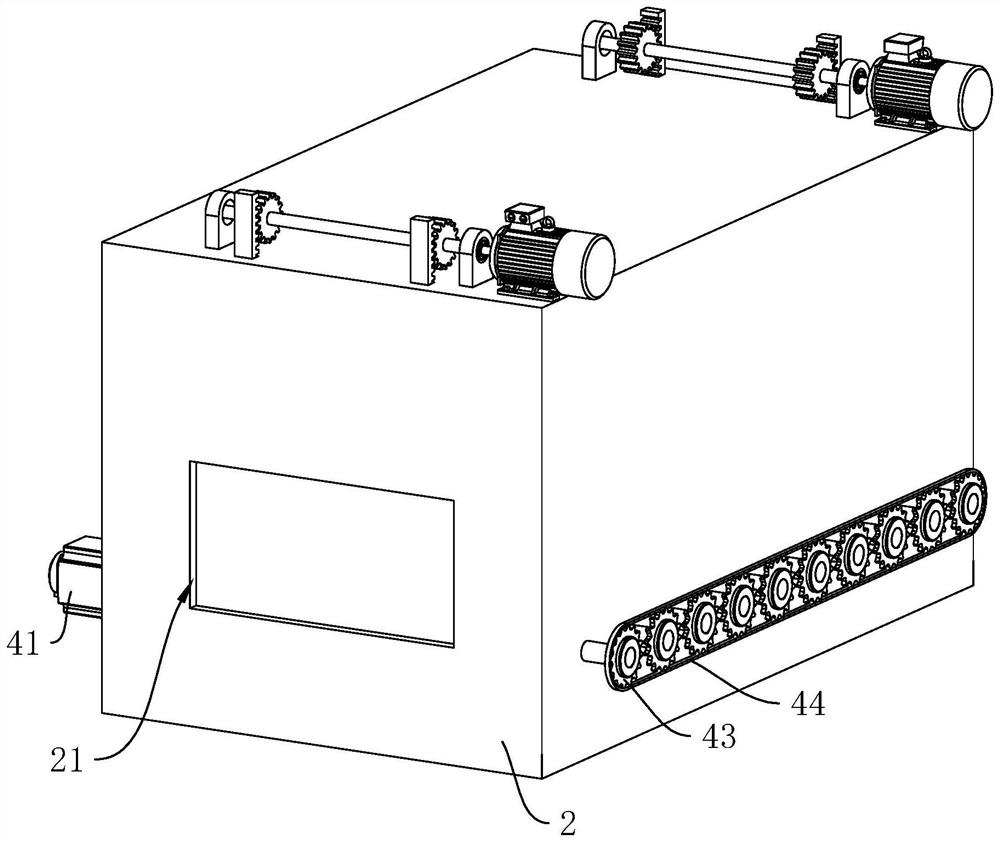

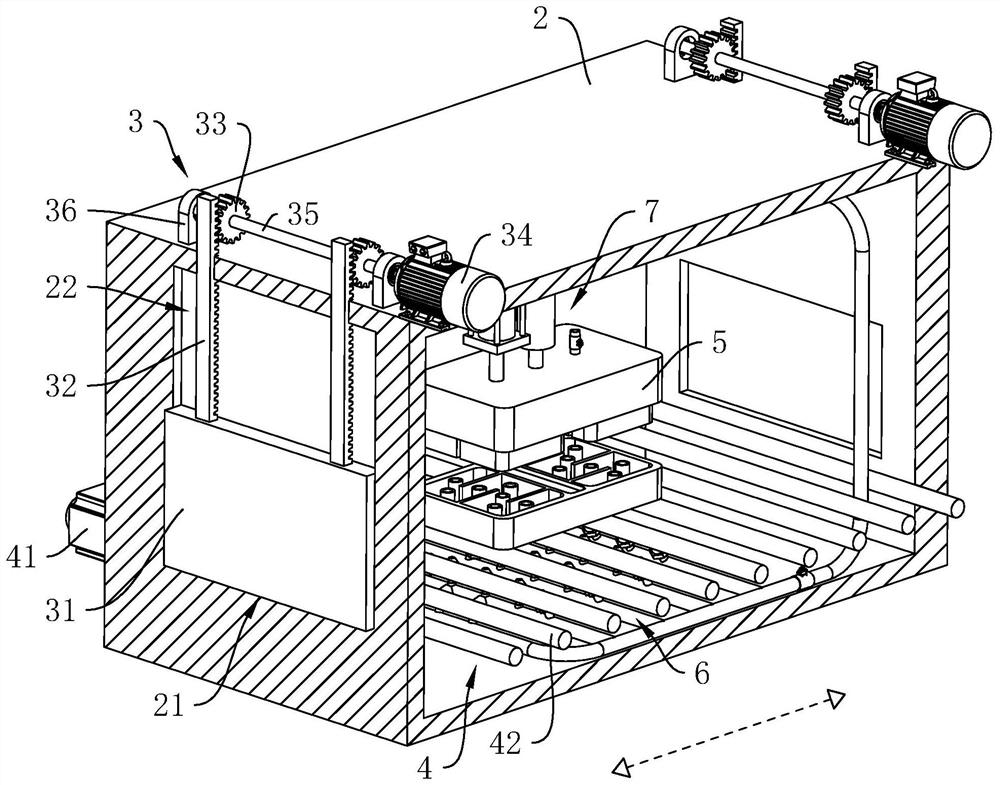

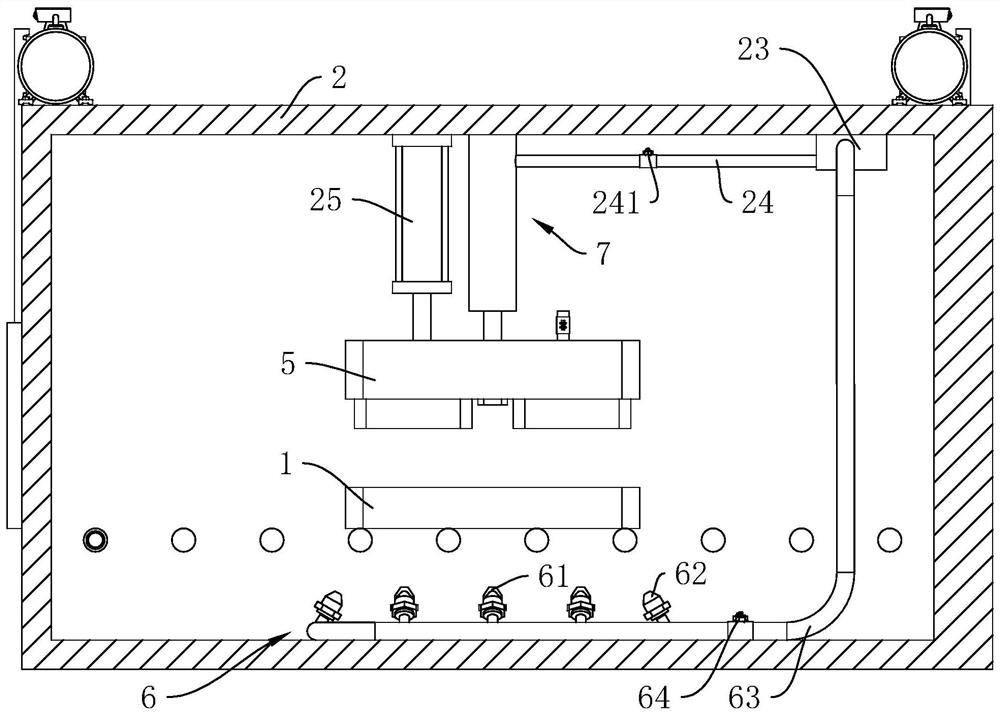

[0038] The embodiment of the present application discloses a fully automated 5G filter cavity production device. refer to figure 1 , the fully automated 5G filter cavity production device includes a cooling box 2, and two of the opposite end faces of the cooling box 2 are provided with flow ports, combined with figure 2 The cooling box 2 is provided with a set of isolation assemblies 3 at both ends of the flow opening 21, so that when no cavity 1 passes through the flow opening 21, the isolation assembly 3 can isolate the air in the cooling box 2 and outside the cooling box 2. The cooling box 2 is provided with a transmission assembly 4, and the cooling box 2 is provided with a cooling mold 5, a lower refrigeration assembly 6 and a telescopic tube assembly 7, and the telescopic tube assembly 7 is connected between the inner surface of the top of the cooling box 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com