Optimization control method for switched reluctance wind power hydrogen production system

A technology of switched reluctance and hydrogen production system, which is applied in the direction of magnetic circuit reluctance control, control system, and electric energy storage system, etc. It can solve the problems of difficult to achieve double-layer optimization of structure, high cost of experiment and maintenance, and long test bench time To achieve the effect of promoting hydrogen production, suppressing electromagnetic torque fluctuations, improving power generation efficiency and power generation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

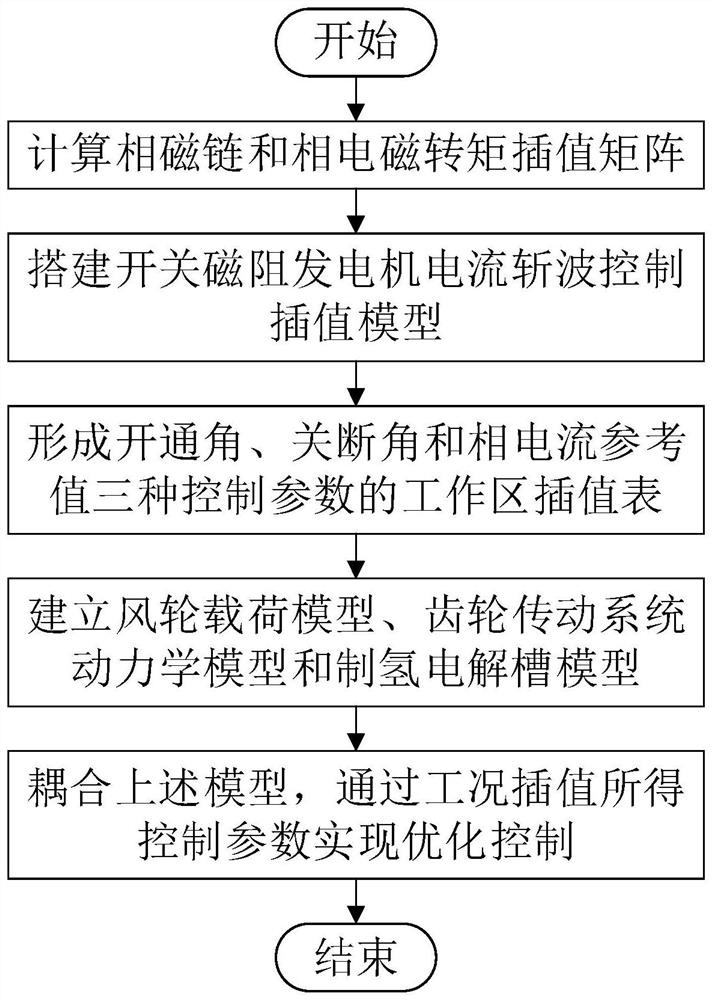

[0045] Such as figure 1 As shown, the present invention is based on the finite element calculation and numerical interpolation processing method, combined with the simulated annealing optimization algorithm, and comprehensively considers that the actual speed of the generator in the switched reluctance wind power system follows the optimal wind rotor speed, and proposes a switched reluctance wind power system. The hydrogen system optimization control method realizes the optimal control of the switched reluctance wind power hydrogen production system, which can make the system have smaller torque ripple under various working conditions, and improve the power generation quality and hydrogen production effect. The method includes the following steps:

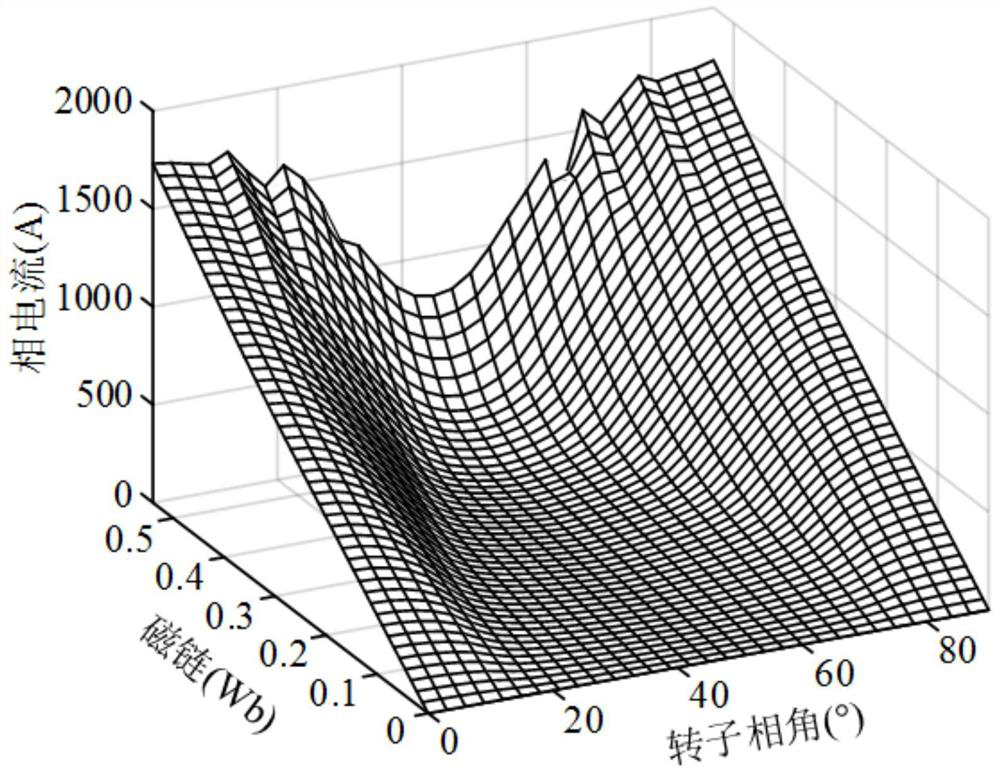

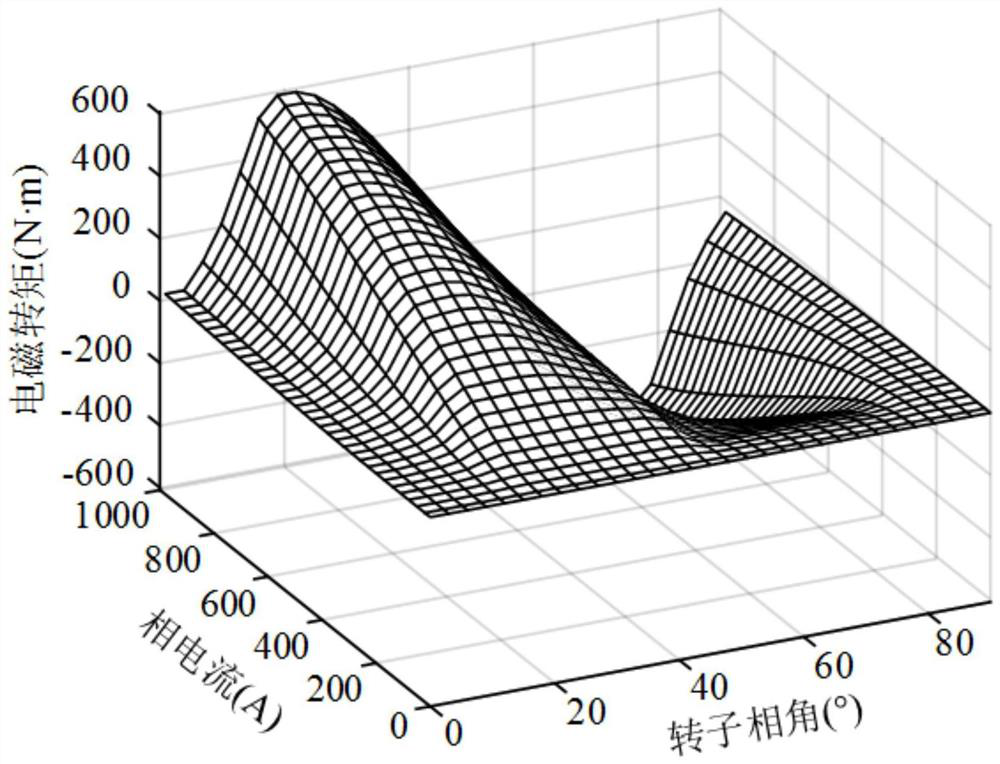

[0046] S1. Use finite element analysis software to implement finite element modeling of switched reluctance gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com