Energy-saving rectification system for hydrolysis of dimethyldichlorosilane

A rectification system and rectification tower technology, applied in the field of energy-saving rectification system, can solve the problems of large consumption of external heat source and cold source, insufficient utilization of waste heat, insufficient energy saving and environmental protection, etc., and achieve saving of heating heat and cooling Quantity, long-term stable industrial operation, and the effect of saving equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

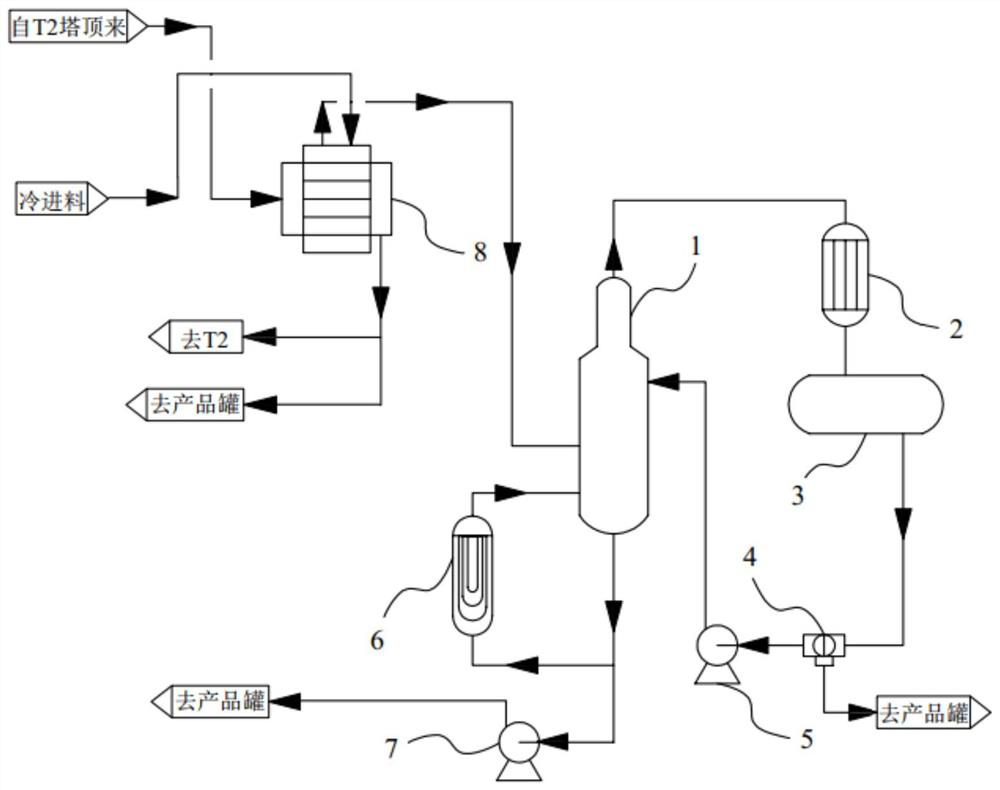

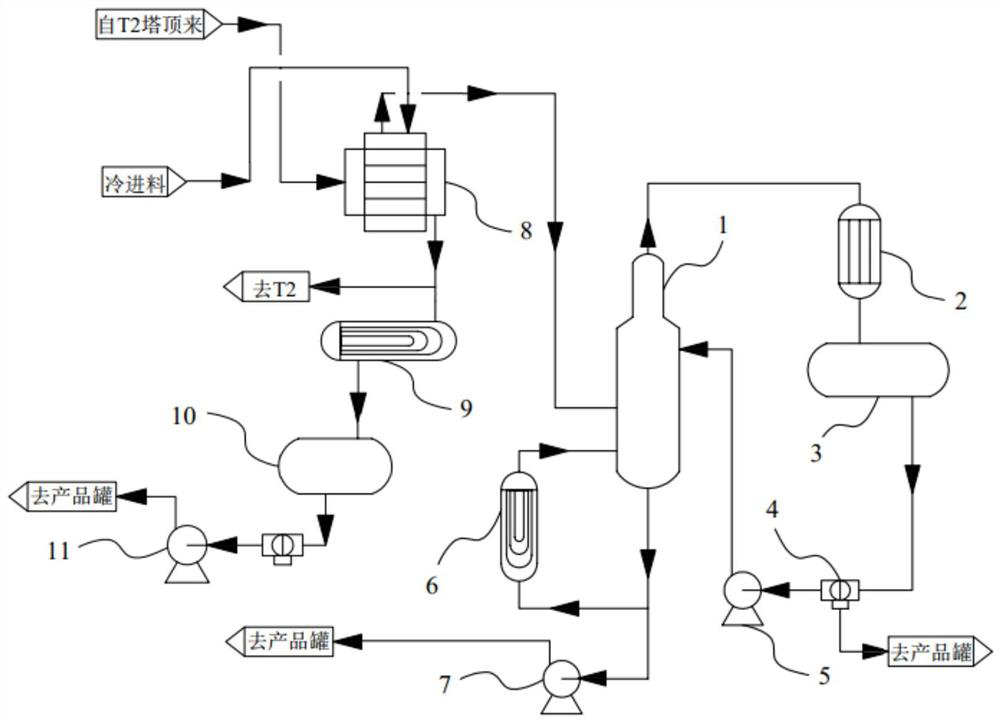

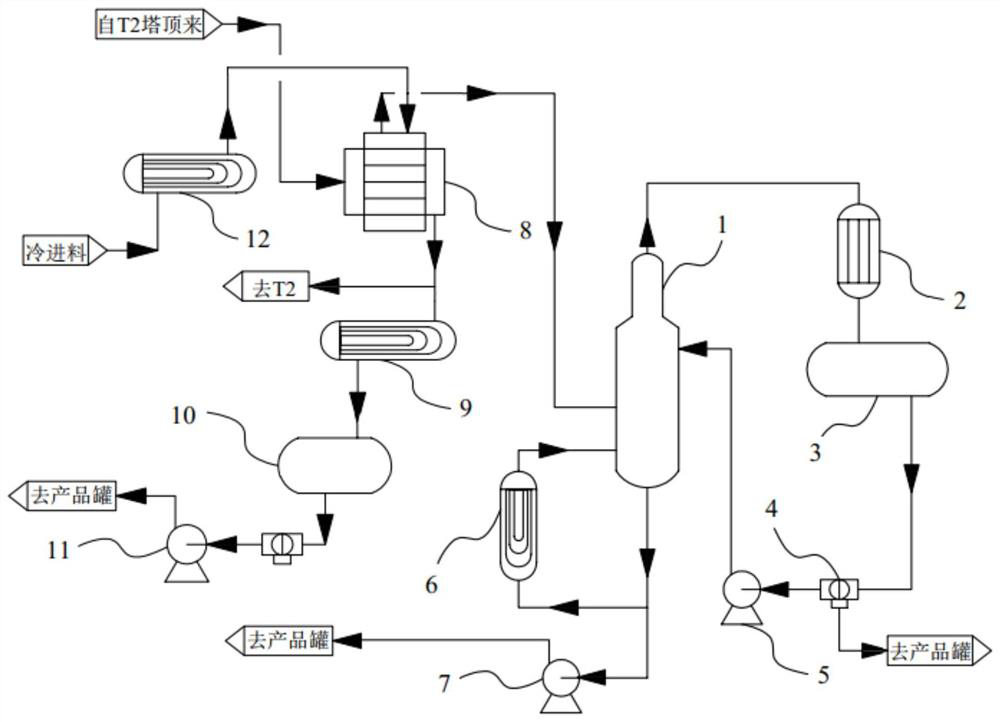

[0082] Such as Figure 4 As shown, this embodiment provides an energy-saving rectification system for the hydrolysis of dimethyldichlorosilane, including the following workflow:

[0083] 1) The cold feed of the first rectifying tower 1 is first preheated by the feed preheater 12, then passes through the shell side of the first feed heater 8 and the shell side of the second feed heater 13 in sequence, and finally Enter the first rectification tower 1 through the pipeline to carry out the rectification operation.

[0084] 2) After the cold feed is separated by rectification in the first rectification tower 1, the output from the tower top is cooled by the tower top cooler 2, and after being transported to the reflux tank 3, part of it passes through the pre-pump filter 4 and the reflux pump 5, Reflux to the top of the first rectification tower 1, and part of the output enters the product tank or the next rectification tower.

[0085] 3) The extracted material from the tower ke...

Embodiment 2

[0089] In this embodiment, the actual working process of the buffer splitter plate provided by the heat exchanger is as follows:

[0090] After using the buffer splitter plate of the present invention, when the fluid feed enters the shell of the heat exchanger through the shell-side inlet, it directly impacts on the bottom plate of the buffer splitter plate, and the tube bundle is basically not directly impacted by the high-speed fluid. A part of the fluid feed washes the side plates on both sides of the buffer splitter plate on the buffer splitter plate, and is discharged from the through holes on the side plates and falls to the tube bundle for heat exchange. The other part of the fluid is guided by the arc-shaped bottom plate of the buffer splitter plate, flows downward from both ends along the arc of the shell, and when it flows through the split holes provided at both ends of the bottom plate, part of the fluid falls from the split holes to the tube bundle for heating. Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com