High-temperature gas-solid mixed phase separation equipment

A technology for separation equipment and mixed phases, applied in separation methods, dispersed particle separation, combined devices, etc., can solve problems such as high-temperature plastic deformation, metal oxidation, and failure of separation equipment, and achieve the effect of avoiding high-temperature oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

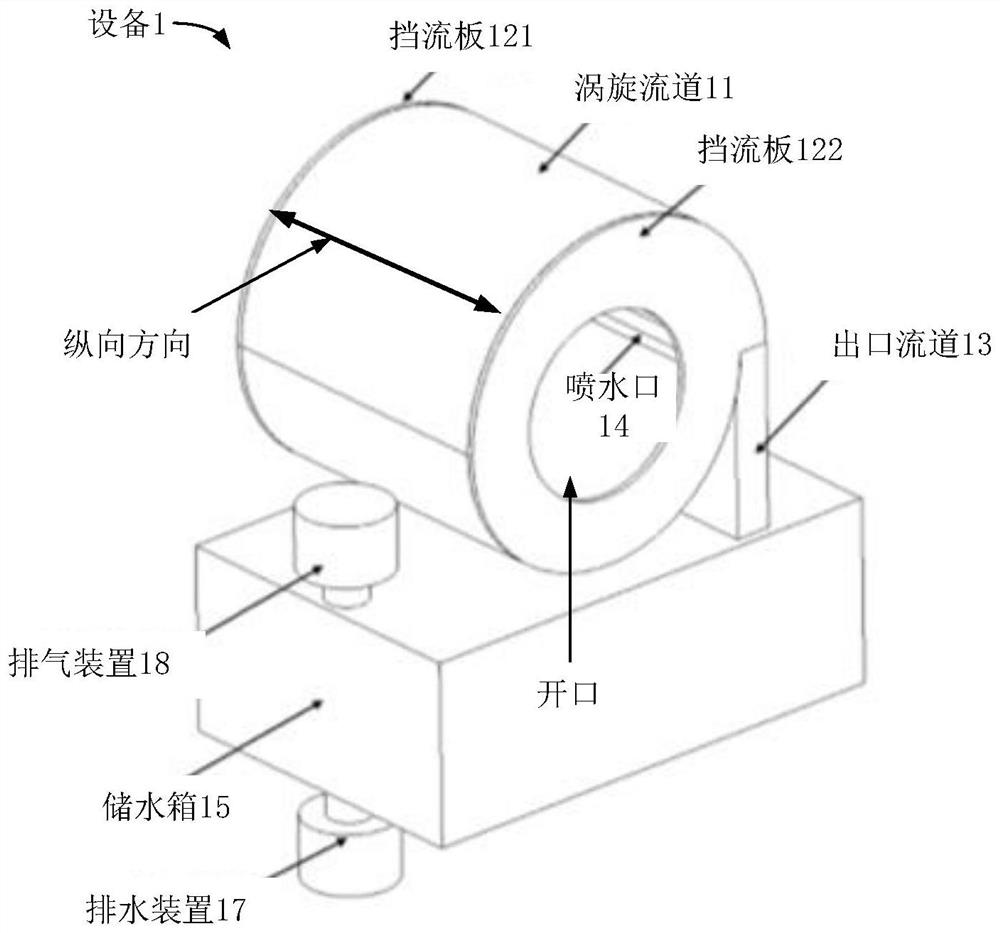

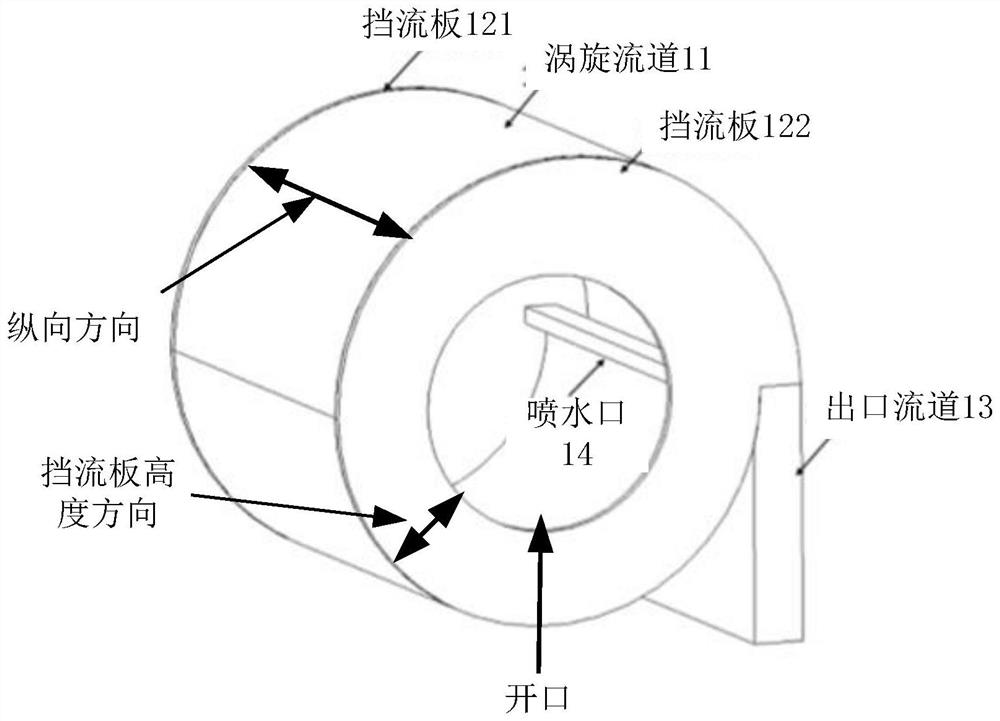

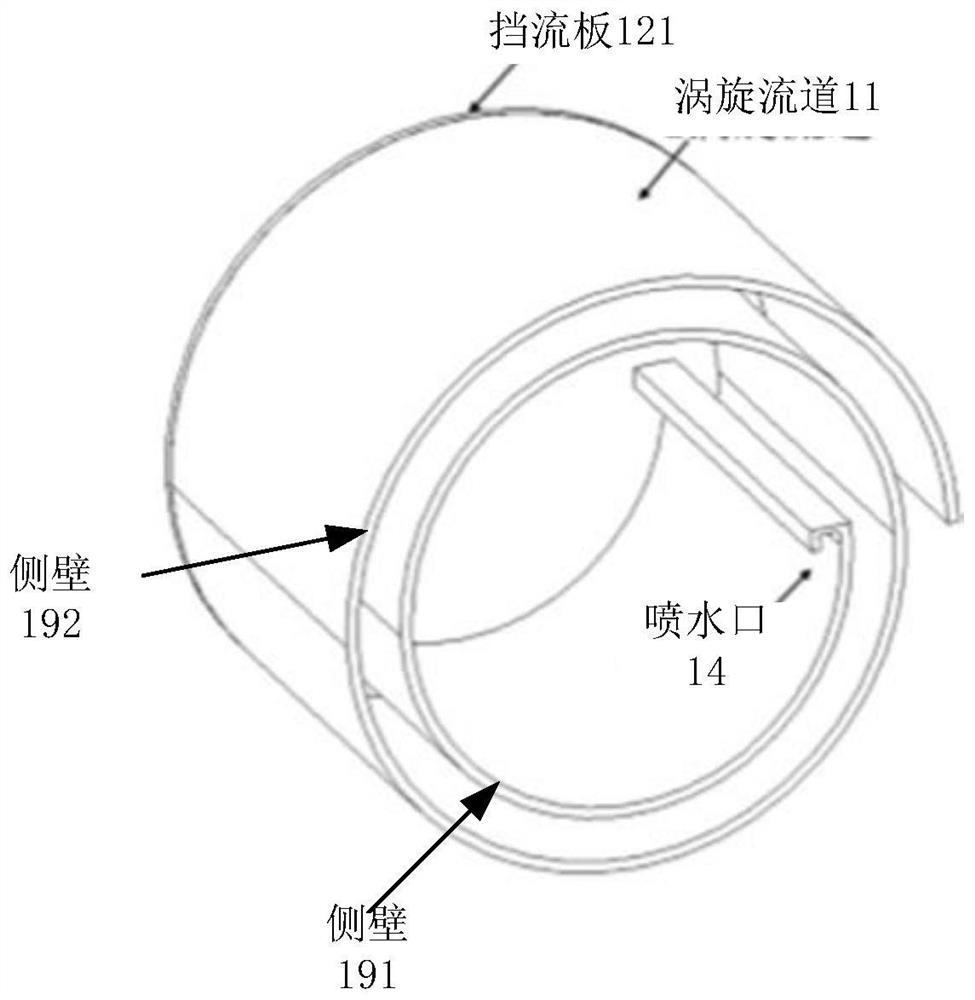

[0094] use Figure 1A In the shown device, the number of turns of the side wall included in the vortex channel 11 needs to be ≥1. Wherein, the more the number of turns of the side wall included in the vortex channel 11 is, the higher the separation efficiency of the gas-solid mixed phase is, and the better the cooling effect is. The equipment parameters and test results of the vortex channel 11 with different turns are shown in Table 1.

[0095] Wherein, the radius of the innermost circle of the vortex channel 11 is 200 mm, the wall thickness of the vortex channel 11 is 10 mm, and the distance between adjacent side walls in the side walls included in the vortex channel 11 is respectively 0 mm (when only one side wall is included). ) and 40mm, the longitudinal length of the vortex channel 11 is 500mm, and the height of the nozzle of the vortex channel 11 is 10mm. The water spray speed of the water nozzle of the vortex flow channel 11 is 30m / s, and when the distance between adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap