Automobile connecting rod production process

A technology of automobile connecting rod and production process, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems that cast aluminum cannot meet the strength requirements, manual removal is time-consuming and labor-intensive, etc., to achieve ingenious perfection of process, cost control, cutting high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

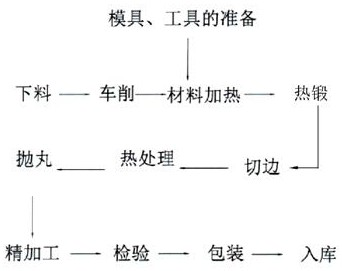

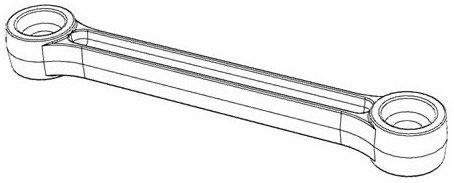

[0040] Refer to attached Figure 1-5 , a kind of automobile connecting rod production process, the steps are as follows:

[0041] Step 1, blanking, select the aluminum rod, the aluminum rod is ∅85 mm aluminum rod made of 6082 material, and the blanking length is 655±1 mm; or the ∅85 aluminum rod made of 6082 material is used, and the blanking length is 655±1 mm.

[0042] Step 2, turning, turning the ∅85×655±1 mm aluminum rod into a forged billet with the two heads of the aluminum rod being ∅80±0.2×117±1 mm and the middle aluminum rod being ∅48±0.2 mm; the aluminum rod The two heads are near the end of the middle aluminum rod for a transition fillet R20mm.

[0043] Step 3. Before hot forging, put the turned forging blank into the heating and holding furnace, raise the temperature to 480°C after 8 hours, and keep the heat for 4 hours to keep the aluminum rod at 470~480°C. The heating should be uniform, and there should be no underheating. and over-burning defects, blanks with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com