Method for producing thin-gauge high-strength structural steel plate by steckel mill

A technology of steel coil rolling mill and structural steel plate, which is applied in the field of metallurgy, can solve the problems of long process, few applications, and many production processes, etc., and achieve the effects of excellent impact performance, simple production process, and good shape quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

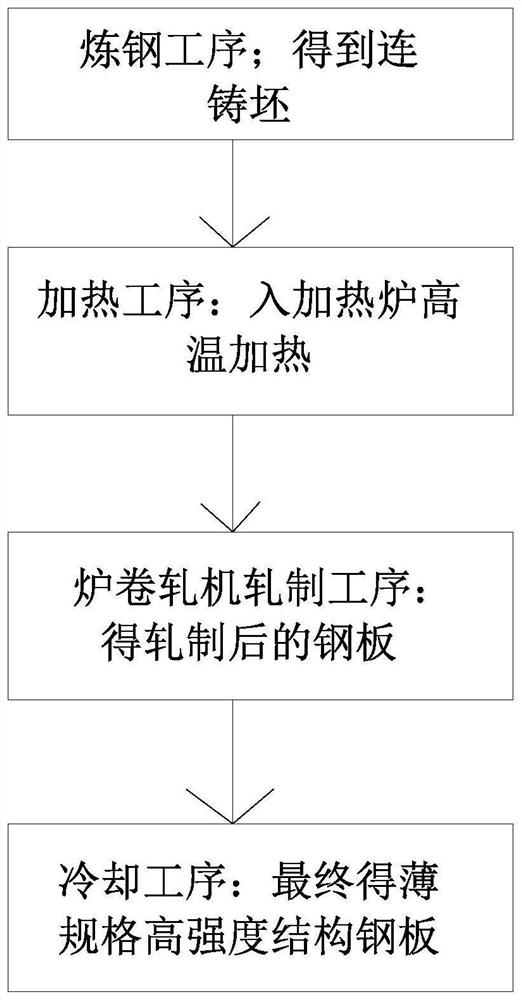

Image

Examples

Embodiment 1

[0033] The thickness of the SM570 steel plate is 6mm, and the following composition ratio and production method are adopted. The production method of this steel plate is as follows:

[0034] (1), steelmaking process: composition content (wt) is C 0.177%, Mn 1.49%, P 0.016%, S 0.006%, Si 0.25%, Alt 0.031%, Nb 0.042%, V 0.045%, CEV 0.44%, The rest is Fe and impurities; smelting according to the above composition, the thickness of continuous casting slab is 150mm;

[0035] (2), heating process: the heating coefficient of the billet is 10.3min / cm, and the heating temperature is 1265°C;

[0036] (3) Rolling process: use the coiler in the furnace before and after the main rolling mill. During the rolling process of the 6mm thin coil plate, the steel plate is coiled in the furnace for heat preservation treatment to reduce the temperature drop rate of the steel plate during the rolling process ;Using conventional rolling method, the final rolling temperature of the steel plate is 828...

Embodiment 2

[0040]The thickness of the SM570 steel plate is 8mm, and the following composition ratio and production method are adopted,

[0041] The production method of this steel plate is as follows:

[0042] (1) Steelmaking process: composition content (wt) is C 0.17%, Mn 1.53%, P 0.014%, S 0.003%, Si 0.31%, Alt 0.036%, Nb 0.045%, V 0.057%, CEV 0.44% , and the rest are Fe and impurities. According to the smelting of the above components, the thickness of the continuous casting slab is 150mm;

[0043] (2), heating process: the heating coefficient of the billet is 10.7min / cm, and the heating temperature is 1250°C;

[0044] (3) Rolling process: use the coiler in the furnace before and after the main rolling mill. During the rolling process of the 8mm thin coil plate, the steel plate is coiled in the furnace for heat preservation treatment to reduce the temperature drop rate of the steel plate during the rolling process ;Using conventional rolling method, the final rolling temperature o...

Embodiment 3

[0048] The thickness of the SM570 steel plate is 10mm, and the following composition ratio and production method are adopted,

[0049] The production method of this steel plate is as follows:

[0050] (1) Steelmaking process: composition content (wt) is C 0.16%, Mn 1.58%, P 0.013%, S 0.005%, Si 0.33%, Alt 0.034%, Nb 0.038%, V 0.052%, CEV 0.44% , and the rest are Fe and impurities. According to the smelting of the above components, the thickness of the continuous casting slab is 150mm;

[0051] (2), heating process: the heating coefficient of the billet is 11.2min / cm, and the heating temperature is 1240°C;

[0052] (3) Rolling process: use the coiler in the furnace before and after the main rolling mill. During the rolling process of the 10mm thin coil plate, the steel plate is coiled in the furnace for heat preservation treatment to reduce the temperature drop rate of the steel plate during the rolling process ;A two-stage rolling method is adopted, the two-stage rolling st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com