Crystal growth bubble eliminating device and method for eliminating crystal growth bubbles

A technology for crystal growth and bubble elimination, which is applied in the direction of crystal growth, single crystal growth, single crystal growth, etc. It can solve the problems of long bubble time, adding crystals, and delaying crystal growth, so as to improve the success rate, eliminate bubbles, and save preparations the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

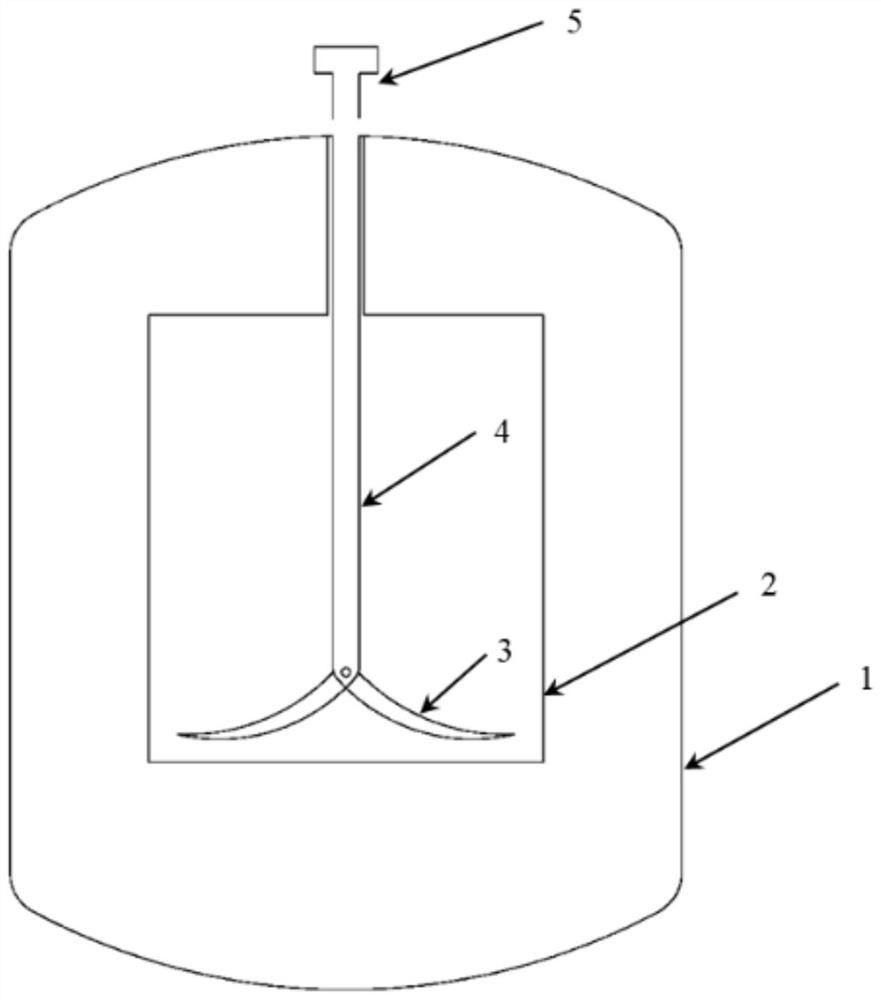

[0023] This embodiment protects a bubble elimination device, which includes a crystal growth tank 1 , a crystal carrier 2 , a rotary fan blade 3 , a connecting shaft 4 and a motor 5 . The crystal carrier 2 is inside the crystal growth tank 1; the motor 5 is outside the crystal growth tank; the crystal carrier 2 has a hollow shaft; the connecting shaft 4 passes through the hollow shaft; the connecting shaft 4 is hinged to the rotary fan blade 3; The shaft 4 drives the rotary fan blade 3 to rotate; the rotary fan blade 3 is two pieces, arc-shaped, and made of polytetrafluoroethylene. The crystal carrier is a rectangular frame. One end of the rotary fan blade 3 is hinged to the connecting shaft 4, and the fan blade 3 can shrink to a state perpendicular to the ground or expand to a state horizontal to the water surface. The rotating fan blade is made of arc-shaped polytetrafluoroethylene. The rotary fan blade 3 in this embodiment can rotate through the center of the connecting s...

Embodiment 2

[0025] The method for eliminating crystal growth bubbles using the crystal growth bubble elimination device of Embodiment 1 includes: extending the rotary fan blade into the hollow shaft of the crystal carrier until the rotary fan blade touches the platform surface of the crystal carrier, and pressing down , so that the rotary fan blade is in an open horizontal state, and the motor drives the rotary fan blade to rotate through the connecting shaft to eliminate air bubbles on the platform surface of the crystal carrier. The rotating speed of the rotary fan blade is 60r / min. After the elimination is completed, the upper surface of the rotary fan blade is in contact with the upper surface of the crystal carrier, so that the rotary fan blade returns to the contracted vertical state, so that it can be taken out smoothly. The crystals are KDP crystals or DKDP crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com