Preparation method and device of water-based waterproof Pu artificial leather

A preparation device and technology for artificial leather, applied to the device for coating liquid on the surface, textiles and papermaking, coating, etc., can solve the problems of water-based PU, etc., achieve high quality, ensure drying quality, and excellent waterproof effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A water-based waterproof Pu artificial leather, comprising a surface layer and a base cloth, the surface layer is made of water-based polyurethane and wood fiber powder, the surface layer accounts for 20-40% of the quality of the PU leather, and the bottom layer accounts for the 30-60% of the mass of the PU leather, and the base cloth accounts for 20-50% of the mass of the PU leather.

[0042] Preferably, the surface layer also includes 2-10% of the water-based color paste, 1-5% of the surface layer thickener and 5-15% of the surface layer filler.

Embodiment 2

[0044] A preparation method of water-based waterproof Pu artificial leather, specifically comprising the following steps:

[0045] S1, slurry preparation: mix water-based polyurethane, wood fiber powder, water-based color paste, filler, thickener with 40%, 10%, 5%, 5%, 2% mass ratio to obtain slurry, control The slurry viscosity is 4000cp;

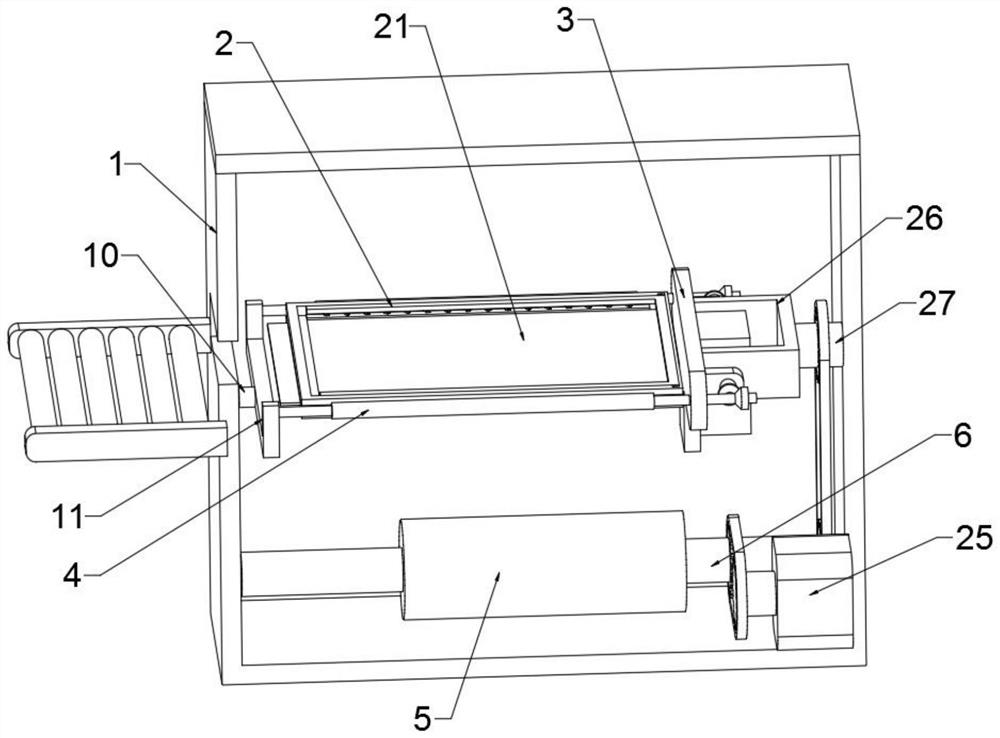

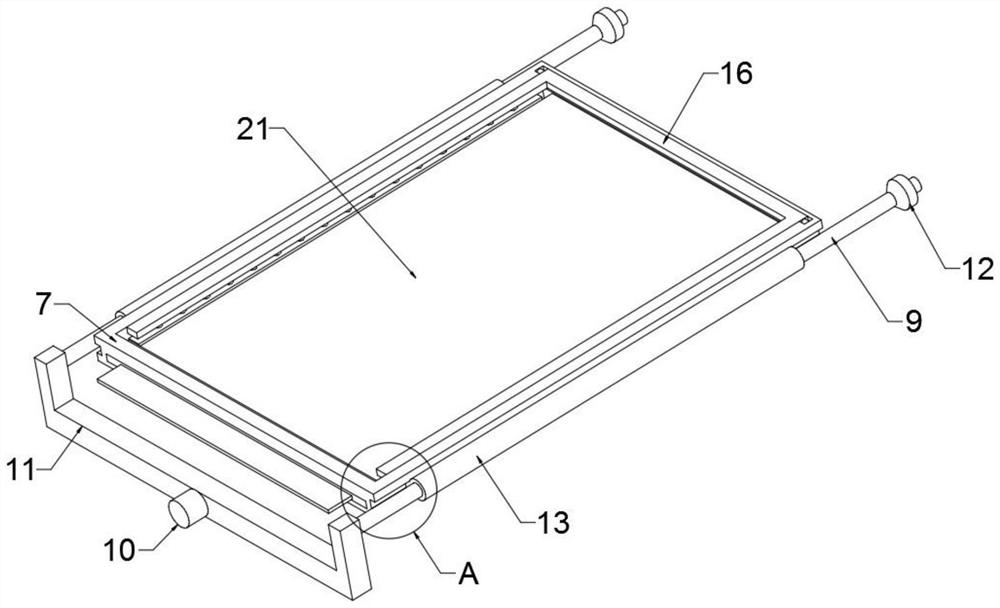

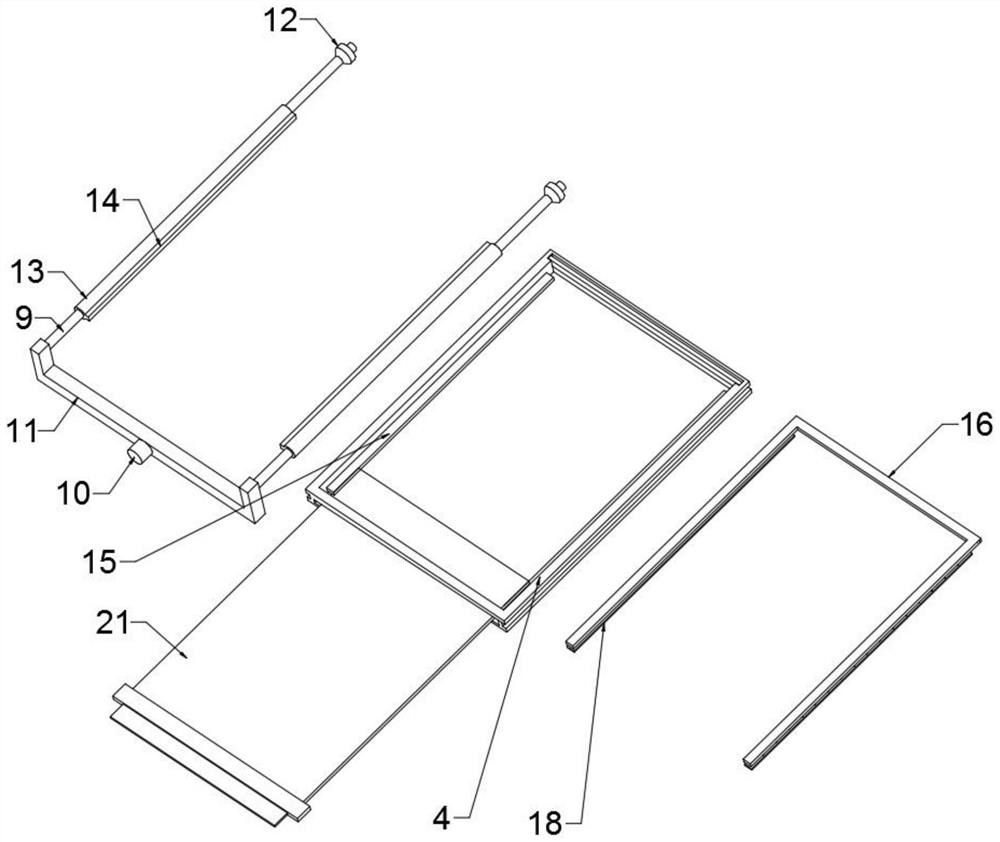

[0046] S2. Coating: Place the release paper flat inside the bearing frame 7, and then evenly scrape the slurry prepared in S1 on both sides of the release paper, with a scraping thickness of 1.5mm;

[0047] S3, one-time drying: send the release paper coated in S2 to the inside of the drying box 1 for drying through the carrier frame 7, the drying temperature is 80 degrees Celsius, the drying time is 5 minutes, and the drying is completed Finally, reset the bearing frame 7, and then repeat steps S2 and S3 once again for the release paper inside the bearing frame 7 to obtain an artificial leather surface layer;

[0048] S4, bonding: the ar...

Embodiment 3

[0052] A preparation method of water-based waterproof Pu artificial leather, specifically comprising the following steps:

[0053] S1, slurry preparation: mix water-based polyurethane, wood fiber powder, water-based color paste, filler, thickener with 50%, 20%, 10%, 10%, 4% mass ratio to obtain slurry, control The slurry viscosity is 7000cp;

[0054] S2. Coating: Place the release paper flat on the inside of the bearing frame 7, and then evenly scrape the slurry prepared in S1 on both sides of the release paper, with a scraping thickness of 2mm;

[0055] S3, one-time drying: send the release paper after coating in S2 to the inside of the drying box 1 for drying through the carrier frame 7, the drying temperature is 100 degrees Celsius, the drying time is 7 minutes, and the drying is completed Finally, the carrying frame 7 is reset, and then the release paper inside the carrying frame 7 is repeated for 2 steps S2 and S3 to obtain an artificial leather surface layer;

[0056] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com