Thermal insulation and sound insulation self-leveling mortar construction trowelling device

A self-leveling mortar and sound insulation technology, which is applied in construction, building maintenance, building construction, etc., can solve the problems of inconvenience, excessive physical exertion in smoothing construction, etc., and achieve the goal of improving efficiency, increasing convenience, and improving construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

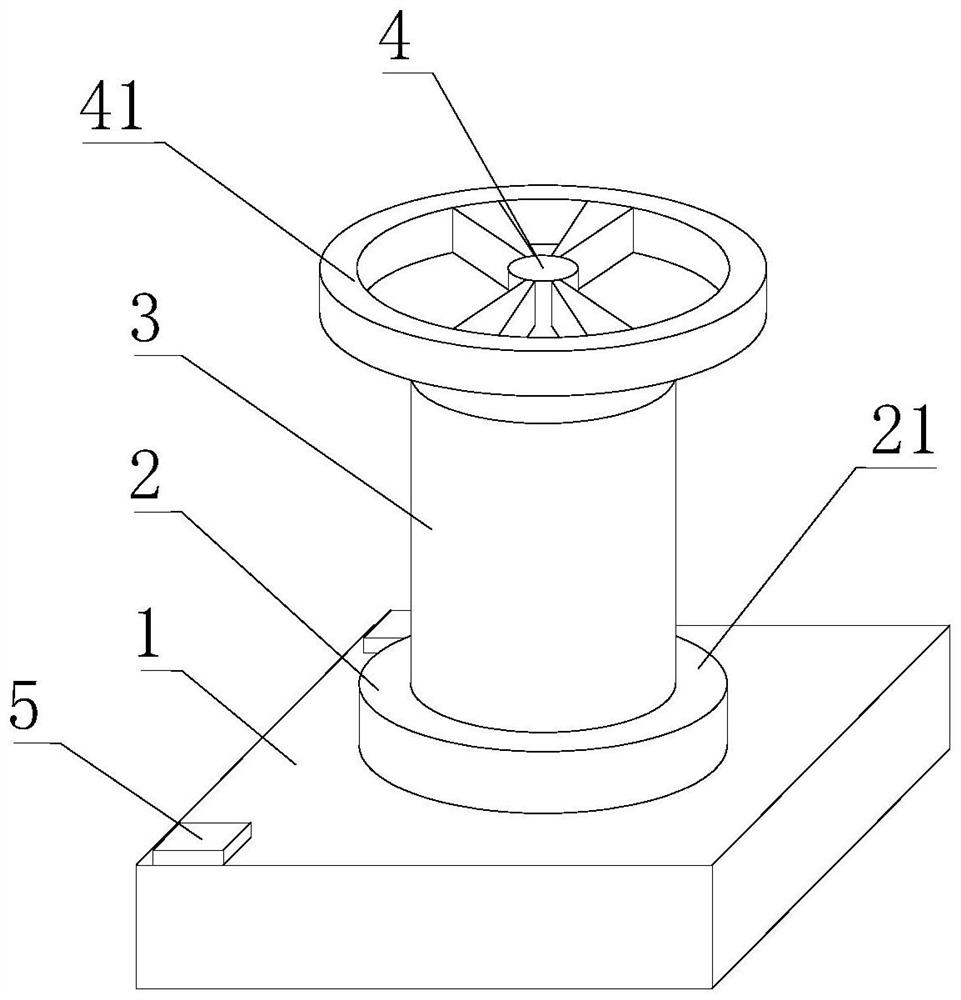

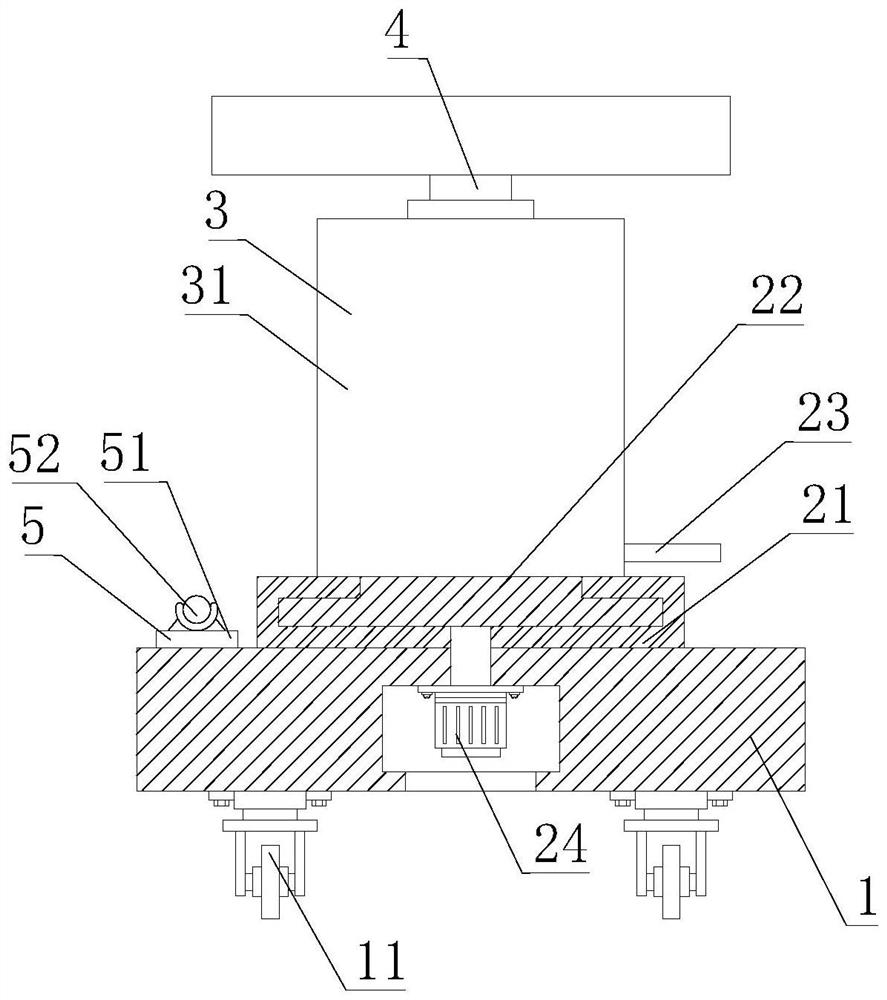

[0035] like Figure 1-7As shown, the present invention provides a thermal insulation and sound insulation self-leveling mortar construction smoothing device, including a counterweight base 1, the bottom of the counterweight base 1 is fixedly equipped with a moving wheel body 11, and the top of the counterweight base 1 is set There is an automatic grinding mechanism 2, the top of the counterweight base 1 is provided with an automatic feeding mechanism 3, and the top of the counterweight base 1 is provided with a bump processing mechanism 5, and the automatic grinding mechanism 2 includes a fixed seat 21 and a stepping motor 24. The fixed base 21 is fixedly installed on the top of the counterweight base 1, and the top of the fixed base 21 is rotatably connected with the turntable 22, and the stepping motor 24 is fixedly installed on the top of the inner cavity of the counterweight base 1, and the output of the stepping motor 24 The shaft is fixedly connected to the bottom of the...

Embodiment 2

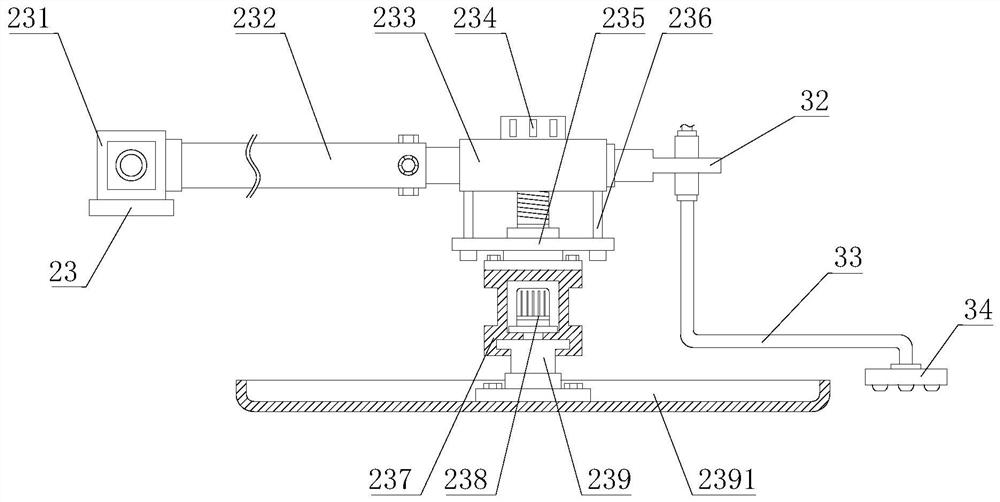

[0037] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the top of the welding block 23 is fixedly installed with a rotating connecting seat 231, and the right side of the rotating connecting seat 231 is rotatably connected with a manual telescopic rod 232, The mobile end of manual telescoping rod 232 is fixedly installed with fixed table 233, and the top of fixed table 233 is threadedly connected with threaded rod 234, and the bottom of fixed table 233 is fixedly welded with sliding seat 236, and the outer wall of sliding seat 236 is slidably connected with sliding plate 235 , the bottom of the threaded rod 234 is rotatably connected with the top of the sliding plate 235, the bottom of the sliding plate 235 is fixedly equipped with a receiving platform 237, the inner cavity of the receiving platform 237 is fixedly installed with a rotating motor 238, and the bottom of the receiving platform 237 is rotatab...

Embodiment 3

[0039] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a connecting block 32 is fixedly installed on the outer wall of the fixed table 233, and a turning tube 33 is fixedly installed on the inner wall of the connecting block 32, and the turning tube The bottom of 33 is fixedly connected with spray plate 34, the input pipe of mud pump 312 is fixedly connected with the left side of storage tank 31, and the left side of storage tank 31 inner cavity is fixedly connected with absorption pipe 313, and the solenoid valve 315 at the bottom The left side is fixedly connected to the top of the transition pipe 33 through a delivery hose, the left side of the solenoid valve 315 at the top is fixedly connected to the left side of the storage tank 31 through a delivery hose, and the left side of the inner cavity of the storage tank 31 is fixedly connected There is a circulation disc 316, the bottom of the circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com