Reverse tunnel-out construction method for shallowly-buried broken surrounding rock tunnel

A technology for crushing surrounding rock and construction method, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of difficult safety control, insufficient supporting rigidity, limited construction space, etc., achieving good settlement control effect and ensuring construction. Quality, the effect of increasing the construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0033] A reverse exit construction method for a small-section tunnel with shallow buried soft and broken surrounding rocks, comprising the following steps:

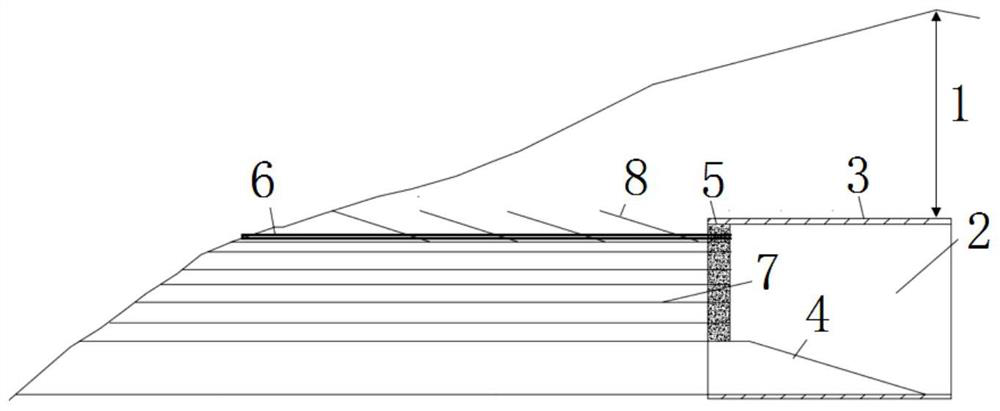

[0034] S1, such as figure 1 As shown, when the construction of the small-section tunnel is close to penetration, the expansion excavation of the pipe shed working room 2 and the construction of initial support 3 are carried out at the position 1 with a buried depth of about 10m, and the expansion of the pipe shed working room is expanded by 60-80cm , the length of the tube shed studio is 6-8m, the initial support of the tube shed studio is I16 steel arch frame, the spacing is 50cm, the thickness of shotcrete is 22cm, and the initial support 3 is provided with an inverted arch 11 as a closed structure;

[0035] S2. Carry out backfilling and compaction construction on the intersecting area 4 of the pipe shed studio 2 and the tunnel face, and the backfilling and compacting area 4 has a trapezoidal structure;

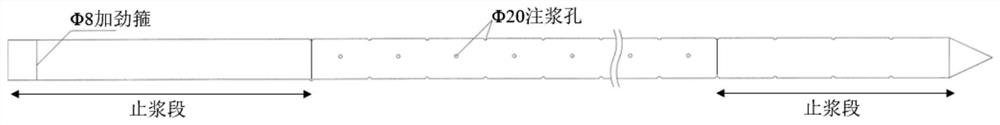

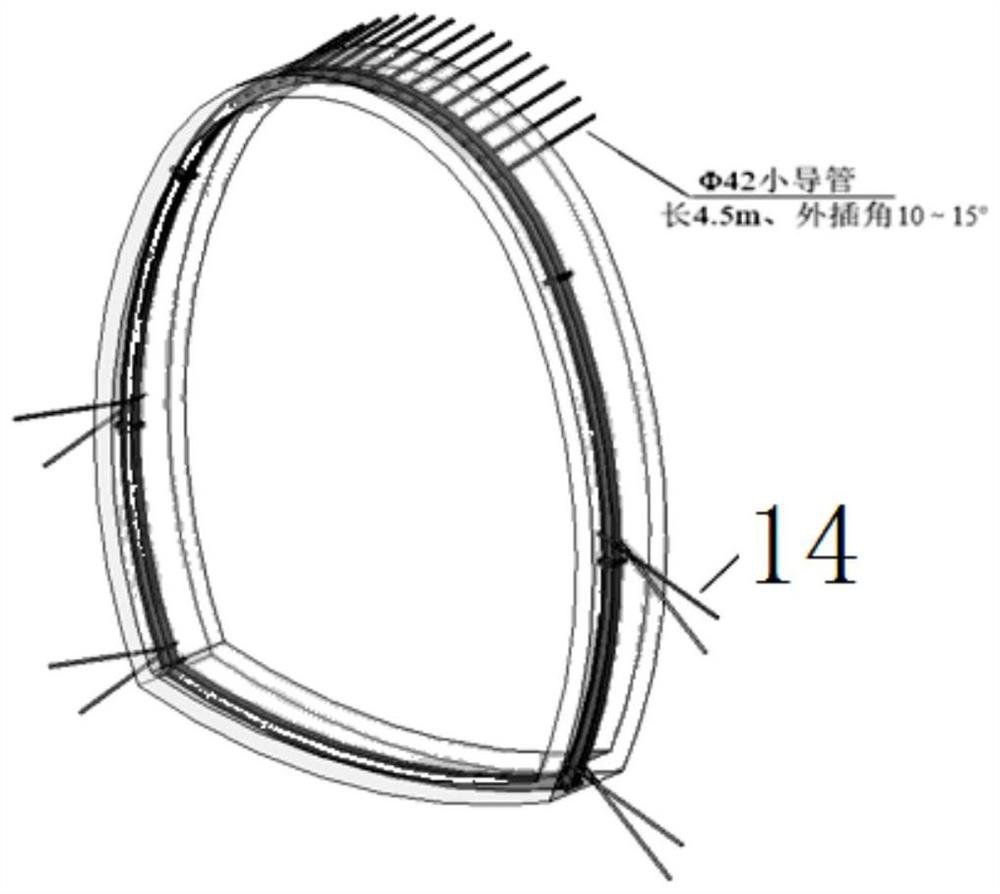

[0036] S3. Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com