Condenser heat transfer tube submerged jet cleaning process test bench and test method thereof

A process test and heat transfer tube technology, applied in the field of condenser heat transfer tube submerged jet cleaning process test bench, can solve the problems of reducing steam turbine efficiency, increasing coal consumption for power generation, reducing cooling water volume, etc., to achieve optimal cleaning effect, The effect of easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

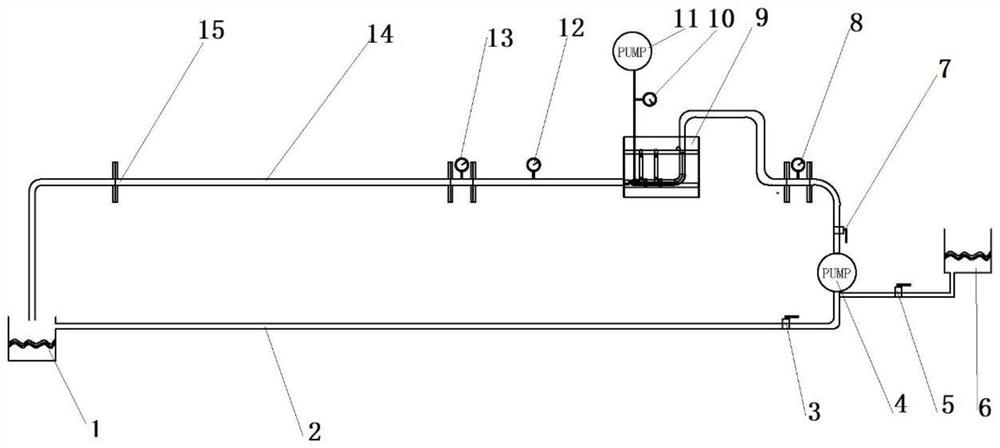

[0042] Example: see attached figure 1 and 2 , the present invention provides a technical solution: a test bench for the submerged jet cleaning process of the condenser heat transfer tube, which includes:

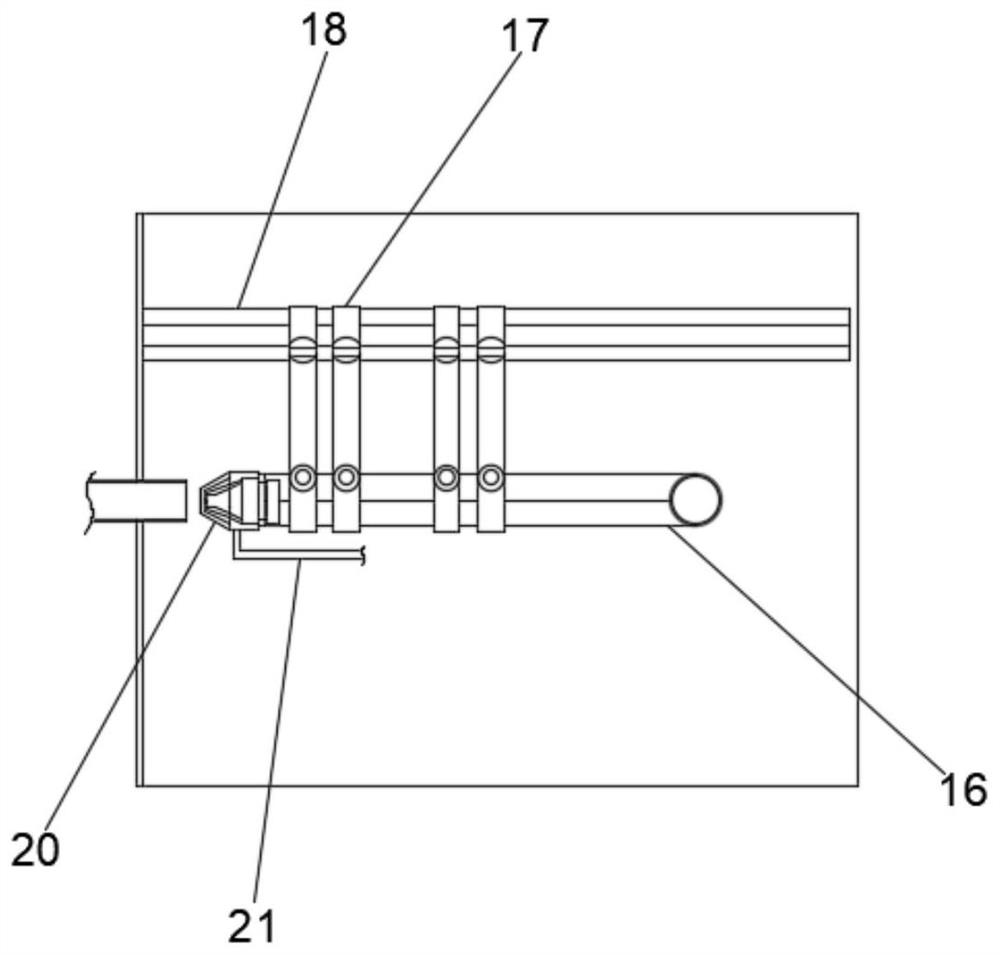

[0043] The simulated water chamber 9 is fixed with a fixed rod 18 inside the simulated water chamber 9;

[0044] The nozzle 20, the nozzle 20 is fixedly connected to the fixed rod 18 by a plurality of fixed connecting rods 17, the fixed rod 18 is fixedly connected to the nozzle 20 by a plurality of fixed connecting rods 17, and the inner cavity of the nozzle 20 is sealed and communicated with one end of the compressed gas circuit pipe 21 , the liquid inlet end of the nozzle 20 is connected to one end of the high-pressure water circuit pipe 16; specifically, the simulated water chamber 9 can simulate the pressure environment of the water chamber, and the nozzle 20 is fixedly installed, and the spraying state of the nozzle 20 is observed during the flushing process , and tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com