Full-three-dimensional sawtooth trailing edge blade of turbomachinery and design method

A technology of impeller machinery and design methods, applied in the direction of mechanical equipment, supporting elements of blades, engine elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

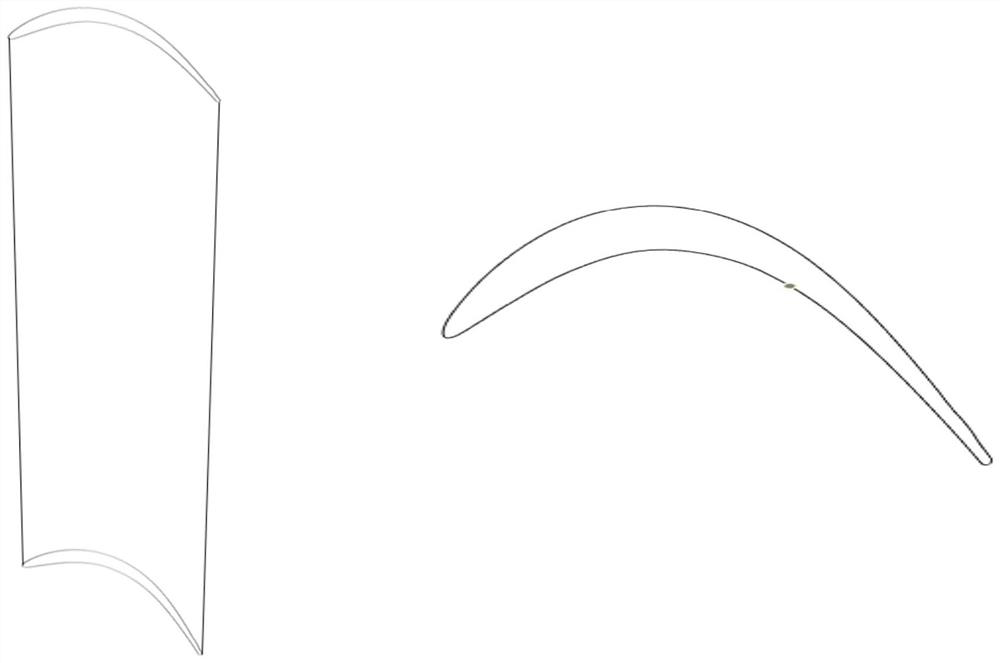

[0056] The design method of the sawtooth trailing edge blade of the turbomachinery involved in the present invention performs coordinate transformation on the basis of the reference blade, and is applicable to but not limited to full three-dimensional blades. In order to illustrate the applicability of the method, in the following content, the present invention takes the last-stage stator blade of the GEE3 low-pressure turbine as an example to illustrate the specific implementation of the method.

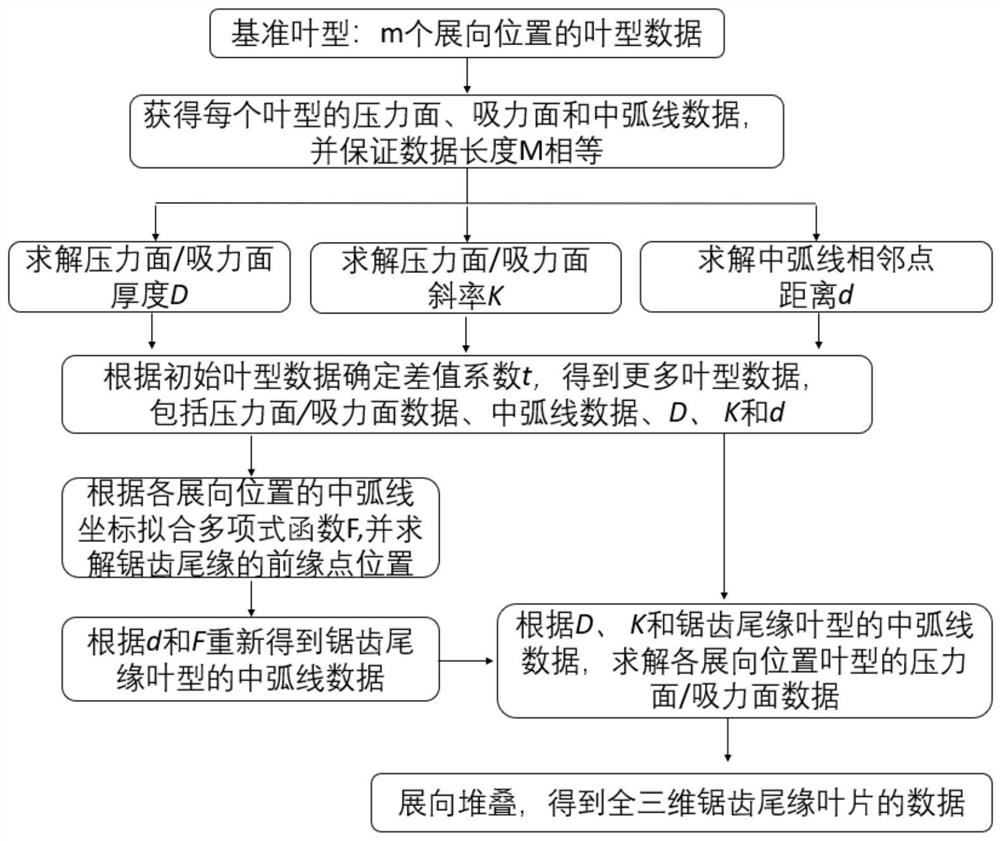

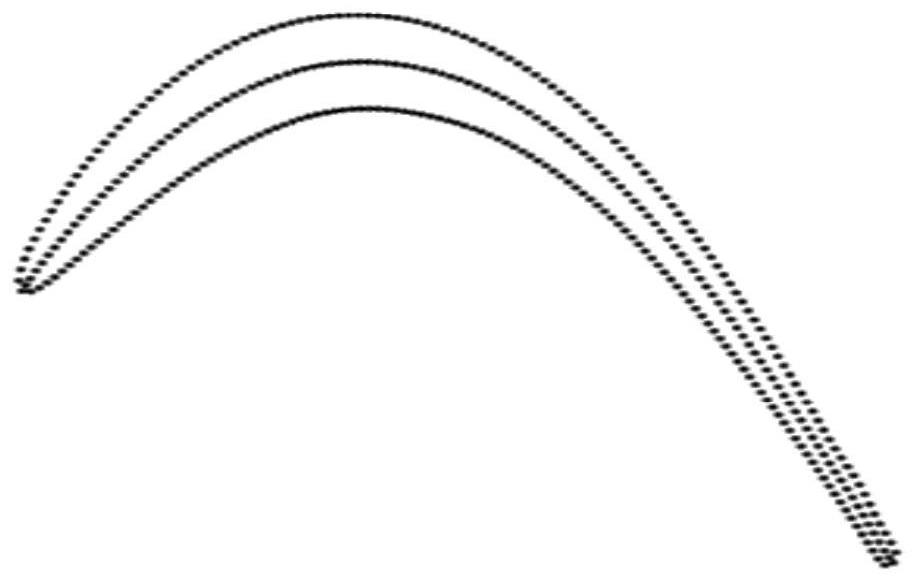

[0057] according to figure 1 Schematic diagram of the method flow chart, see figure 2 — Figure 5 , the present invention includes the following technical solutions:

[0058] 1. Based on the reference blade and according to the actual blade geometry needs, m blade shape coordinate data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com