Plasticizer composition and vinyl chloride resin composition comprising same

A technology of vinyl chloride resin and composition, applied in the field of plasticizer composition and vinyl chloride resin composition comprising the plasticizer composition, can solve the problem of unpleasant odor, high sol viscosity and poor volatile property improvement limitation and other problems, to achieve the effects of excellent migration resistance, small viscosity change over time, and reduction of plasticizer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

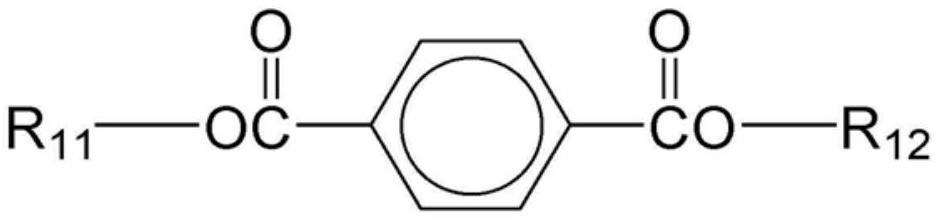

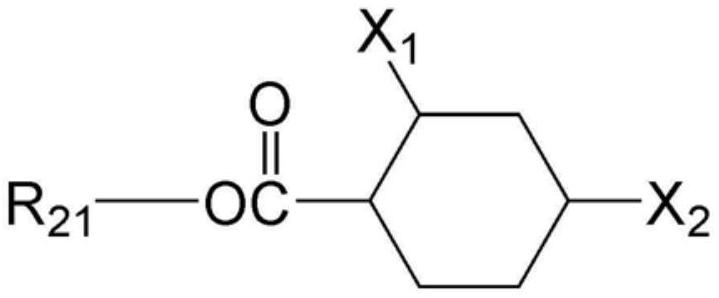

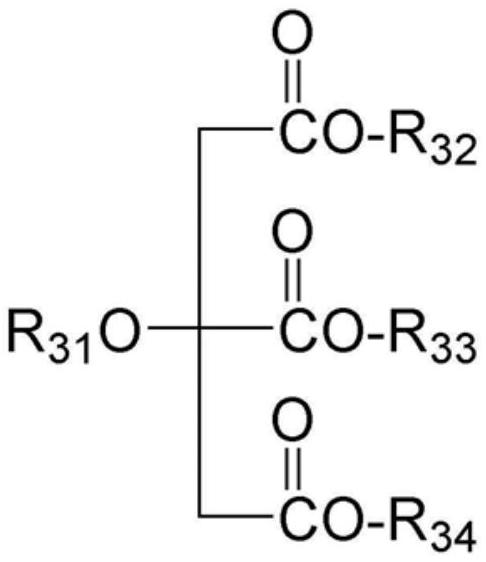

[0138] As described in Table 1 below, based on 100 parts by weight of the plasticizer composition, 40 parts by weight of dioctyl terephthalate (bis(2-ethylhexyl) terephthalate) (DOTP), 50 parts by weight Bis(2-ethylhexyl)cyclohexane-1,4-dicarboxylate (DEHCH) and 10 parts by weight of TBC (tributyl citrate) were mixed to prepare a plasticizer composition.

[0139] 100 parts by weight of polyvinyl chloride were mixed with 60 parts by weight of the above-prepared plasticizer composition using a Mathis mixer to prepare a plastisol.

Embodiment 2 to 7

[0141] A plasticizer composition was prepared by mixing the compounds described in Table 1 below by the content thereof.

[0142] A plastisol was prepared by the same method as in Example 1 except that the plasticizer composition prepared above was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com