Combined process for transalkylation of benzene and heavy aromatics and methylation of toluene

A heavy aromatic hydrocarbon alkylation and combined process technology, which is applied in the direction of condensation between hydrocarbons and non-hydrocarbons to produce hydrocarbons, hydrocarbons, hydrocarbons, etc., can solve the problems of benzene overcapacity, reduce the generation of ethylbenzene, increase The effect of high quality, high para-selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

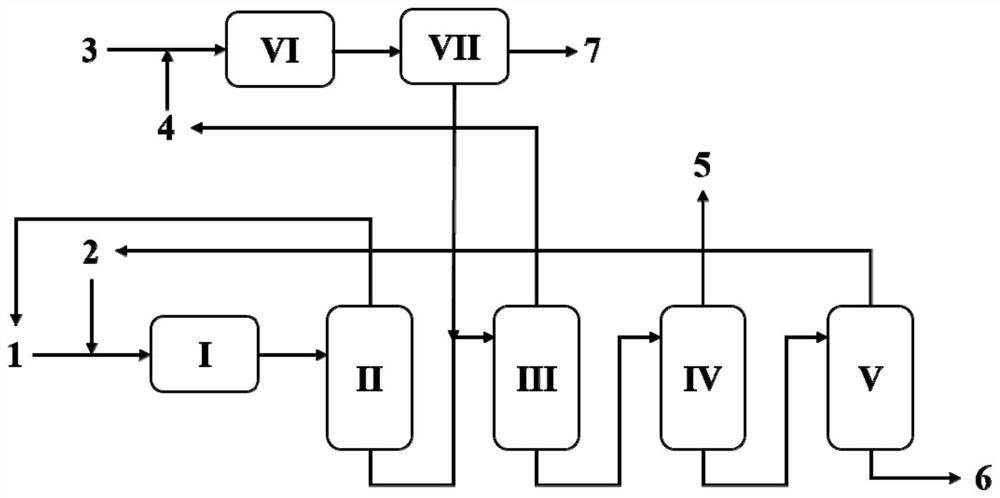

[0045] The schematic diagram of the technological process of this embodiment is as figure 1 shown. The specific implementation is as follows:

[0046] Benzene and C 9 + A is the reaction raw material, and benzene and C are carried out in a fixed-bed reactor under hydrogen conditions. 9 + A transalkylation reaction, the inner diameter of the reactor is 30mm, the length is 100mm, made of stainless steel. The upper and lower sides of the catalyst bed are filled with glass beads with a particle size of 3 mm to distribute and support the air flow. The upper catalyst bed in the reactor is filled with 15 grams of MOR molecular sieve with 0.03% Pt (the amount of Pt is based on the quality of the MOR molecular sieve) , the lower catalytic bed layer is filled with the ZSM-5 molecular sieve (Re consumption is based on the ZSM-5 molecular sieve quality) of 5 grams of loaded 0.15% Re. Reactive benzene / C 9 A / C 10 + The mass ratio of A is 40 / 50 / 10, and the weight space velocity of t...

Embodiment 2

[0051] The schematic diagram of the technological process of this embodiment is as figure 1 shown. The specific implementation is as follows:

[0052] Benzene and C 9 +A is the reaction raw material, and benzene and C are carried out in a fixed-bed reactor under hydrogen conditions. 9 + A transalkylation reaction, the inner diameter of the reactor is 30mm, the length is 100mm, made of stainless steel. The upper and lower parts of the catalyst bed are filled with glass beads with a particle size of 3 mm for air distribution and support, and the upper catalyst bed in the reactor is filled with 10 grams of MOR molecular sieve loaded with 0.15% Re (the amount of Re is based on the quality of the MOR molecular sieve) , the lower catalytic bed layer is filled with 10 grams of ZSM-48 molecular sieves loaded with 0.02% Pt (the amount of Pt is based on the ZSM-48 molecular sieve quality). Reactive benzene / C 9 A / C 10 + The mass ratio of A is 40 / 50 / 10, and the weight space veloc...

Embodiment 3

[0057] The schematic diagram of the technological process of this embodiment is as figure 1 shown. The specific implementation is as follows:

[0058] Benzene and C 9 + A is the reaction raw material, and benzene and C are carried out in a fixed-bed reactor under hydrogen conditions. 9 + A transalkylation reaction, the inner diameter of the reactor is 30mm, the length is 100mm, made of stainless steel. The upper and lower sides of the catalyst bed are filled with glass beads with a particle size of 3 mm to distribute and support the air flow. The upper catalyst bed in the reactor is filled with 10 grams of Beta molecular sieve with 0.15% Re (the amount of Re is based on the quality of Beta molecular sieve) , the lower catalytic bed layer is filled with the ZSM-5 molecular sieve of 10 grams of loading 0.03% Pt (the amount of Pt is based on the ZSM-5 molecular sieve quality). Reactive benzene / C 9 A / C 10 + The mass ratio of A is 40 / 50 / 10, and the weight space velocity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com