Device for producing ammonium sulfate with ammonium bicarbonate as main raw material

A technology of ammonium bicarbonate and ammonium sulfate, applied in ammonia compounds, inorganic chemistry, chemical instruments and methods, etc., to achieve the effect of small investment and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

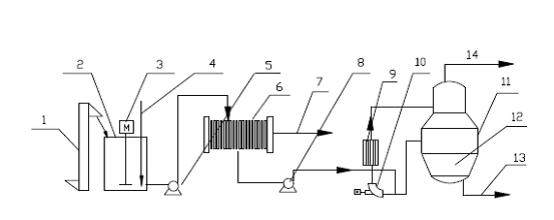

[0018] A factory adopts the present invention to produce ammonium sulfate, and the device is as attached figure 1 .

[0019] The device consists of elevator 1, mixing reaction tank 2, slurry delivery pump 5, filter press 6, filter cake belt conveyor 7, filtrate delivery pump 8, heat exchanger 9, circulating axial flow pump 10, crystallizer 11 and product The belt conveyor 13 is composed of; among them, the mixing reaction tank 2, the slurry delivery pump 5, the filter press 6, the filtrate delivery pump 8, the heat exchanger 9, the circulating axial flow pump 10, and the crystallizer 11 are all connected in sequence through pipelines; The machine 1 is a bucket elevator, the model is HL300, and its material outlet is next to the mixing reaction tank 2; the filter cake belt conveyor 7 is installed under the filter press 6, and the filter press 6 is a plate and frame filter press, the model is BAM50 / 1000-35U, the filter cake outlet is connected to the filter cake belt conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com