Electrode plate as well as preparation method and application thereof

A technology of electrode pole piece and conductive agent, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of high battery production cost, poor safety, and high impedance of solid electrolyte membranes, so as to avoid thermal runaway and improve Safety, the effect of reducing the risk of thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

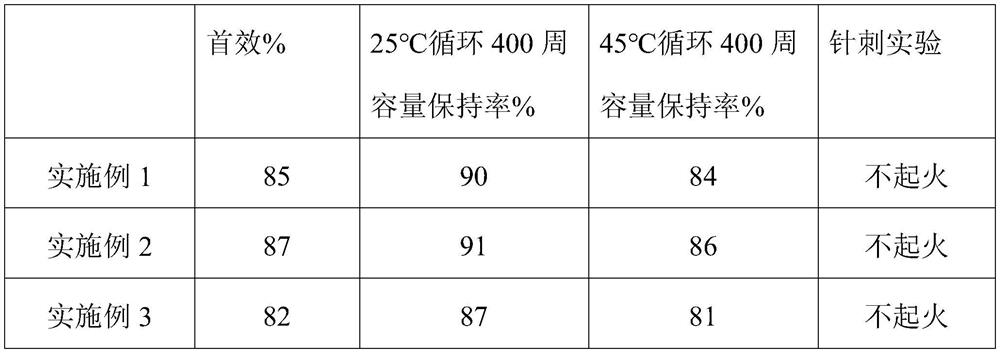

Embodiment 1

[0037] This embodiment provides a soft pack battery, and the preparation method of the positive and negative pole pieces is as follows:

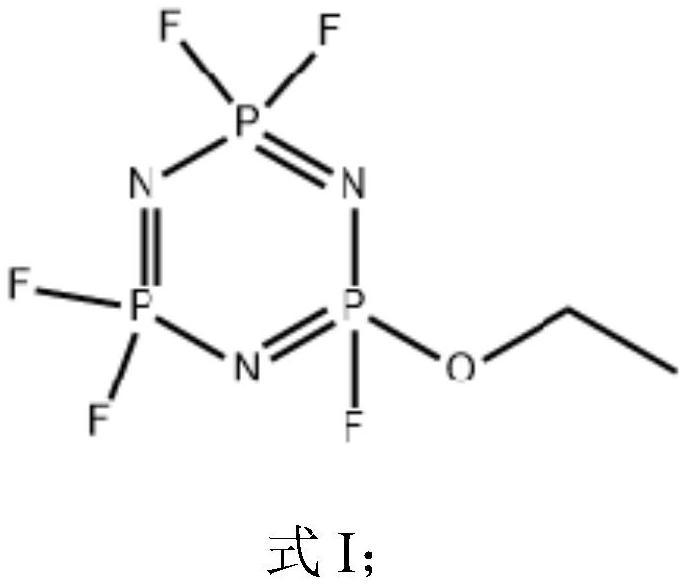

[0038]NCM811, carbon nanotubes, polytetrafluoroethylene resin PTFE and ethoxylated pentafluorocyclotriphosphazene were mixed according to the mass ratio of 95:2:2:1, and the positive active material film was obtained by dry rolling treatment. The positive electrode sheet is obtained by hot-compressing the positive electrode active material sheet film and the current collector at 100°C.

[0039] Graphite material, carbon nanotubes, polytetrafluoroethylene resin PTFE and ethoxylated pentafluorocyclotriphosphazene are mixed according to the mass ratio of 96:1:2:1, and the negative electrode active material film is obtained by dry rolling treatment , hot-compressing the negative electrode active material sheet film with the current collector at 120° C. to obtain the negative electrode sheet.

[0040] The positive and negative pole pieces were d...

Embodiment 2

[0042] This embodiment provides a soft pack battery, and the preparation method of the positive and negative pole pieces is as follows:

[0043] NCM811, carbon nanotubes, polytetrafluoroethylene resin PTFE and ethoxylated pentafluorocyclotriphosphazene are mixed according to the mass ratio of 95.5:2:2:0.5, and the positive active material film is obtained by dry rolling treatment. The positive electrode sheet is obtained by hot-compressing the positive electrode active material sheet film and the current collector at 100°C.

[0044] The graphite material, carbon nanotubes, polytetrafluoroethylene resin PTFE and ethoxylated pentafluorocyclotriphosphazene are mixed according to the mass ratio of 96.5:1:2:0.5, and the negative electrode active material electrode film is obtained by dry rolling treatment , hot-compressing the negative electrode active material sheet film with the current collector at 120° C. to obtain the negative electrode sheet.

[0045] The positive and negati...

Embodiment 3

[0047] This embodiment provides a soft pack battery, and the preparation method of the positive and negative pole pieces is as follows:

[0048] NCM811, carbon nanotubes, polytetrafluoroethylene resin PTFE and ethoxylated pentafluorocyclotriphosphazene were mixed according to the mass ratio of 93:2:2:3, and the positive active material film was obtained by dry rolling treatment. The positive electrode sheet is obtained by hot-compressing the positive electrode active material sheet film and the current collector at 100°C.

[0049] Graphite material, carbon nanotubes, polytetrafluoroethylene resin PTFE and ethoxylated pentafluorocyclotriphosphazene are mixed according to the mass ratio of 94:1:2:3, and the negative electrode active material film is obtained by dry rolling treatment , hot-compressing the negative electrode active material sheet film with the current collector at 120° C. to obtain the negative electrode sheet.

[0050] The positive and negative pole pieces were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com