Production method of flexible integrated battery cell

A production method and flexible technology, which is applied in the field of flexible integrated battery production, can solve the problem that the adhesion of positive and negative active materials is not well resolved, the adhesion of active materials and current collectors cannot solve the problem of falling off, metal collection Fluid deformation is not easy to recover and other problems, to achieve the effect of improving interface compatibility, avoiding interface impedance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

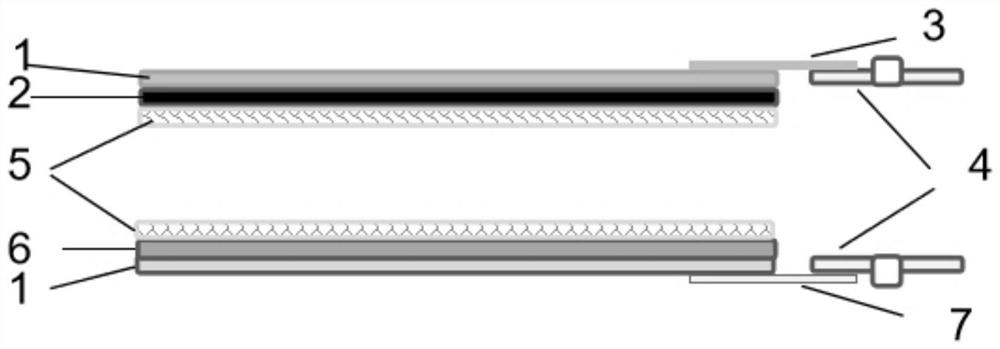

[0060] The preparation process of the flexible self-supporting negative electrode film is different from the preparation process of the flexible self-supporting positive electrode film only in the raw materials of the active material, and the others are the same.

[0061] The specific preparation steps of the flexible self-supporting negative electrode film are:

[0062] Add negative electrode active material, conductive agent, binder to solvent, the mass ratio of negative electrode active material and conductive agent is 7.5:1~9:0.5, the mass ratio of negative electrode active material and binder is 7:1~9: 0.5, the solid content of the negative electrode slurry is 500mg / mL~67mg / mL, the negative electrode active material is one of ternary materials, graphite, silicon carbon, and the conductive agent is carbon nanotubes, graphene, carbon fiber, acetylene black, One or more of carbon black and Ketjen black, and the binder is one or two of polyurethane, polyacrylonitrile, polyeth...

Embodiment 1

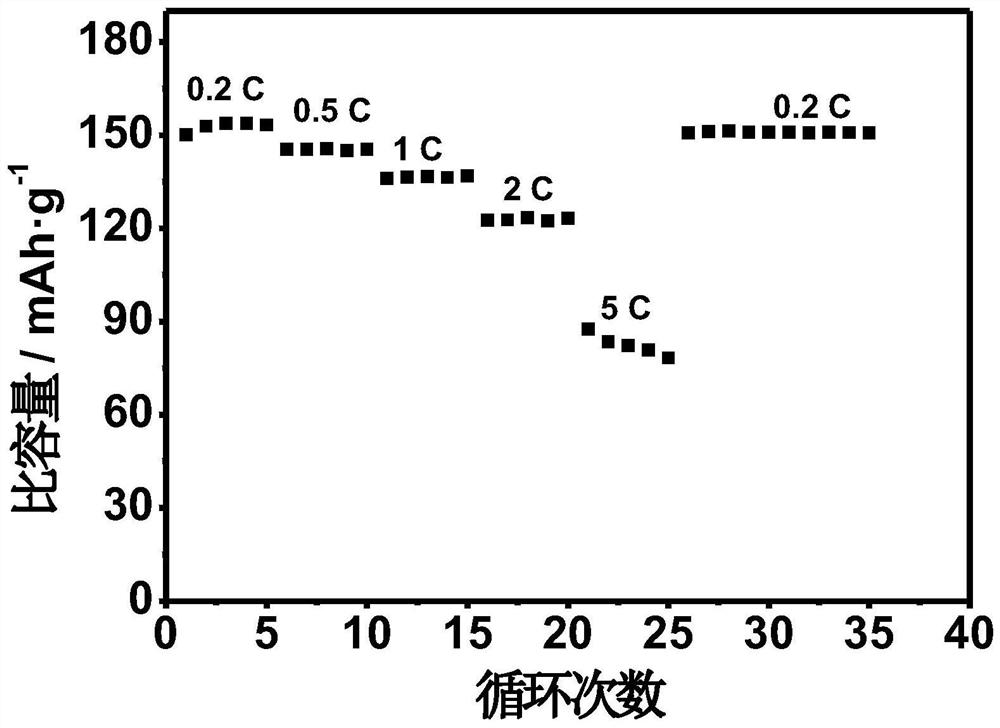

[0077] Preparation of positive electrode slurry: Weigh lithium iron phosphate, carbon nanotubes, and polyurethane (PU) with a mass ratio of 15:3:2, add them to THF, and perform ball milling and dispersion at a speed of 400 rpm by a ball mill Treat for 3 hours, and prepare positive electrode slurry with a solid content of 400mg / mL;

[0078] Preparation of negative electrode slurry: Weigh graphite, carbon nanotubes, and polyurethane (PU) with a mass ratio of 15:3:2, add them to THF, and perform ball milling dispersion treatment for 3 hours at a speed of 400 rpm through a ball mill , prepared into a negative electrode slurry with a solid content of 400 mg / mL;

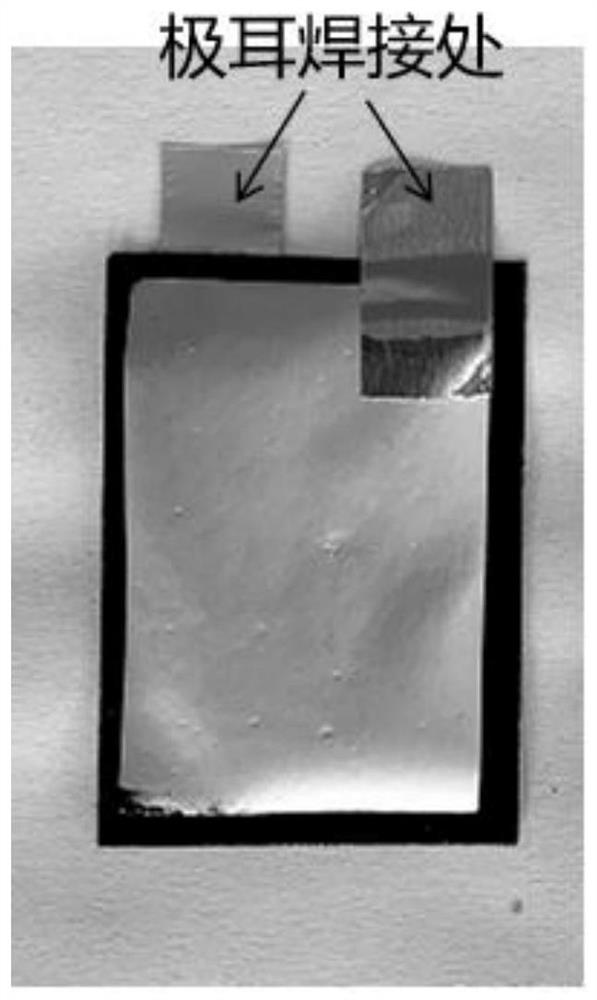

[0079] The positive electrode slurry is coated, dried, and peeled off to obtain a flexible self-supporting positive electrode film. In particular, the substrate used for coating is a flexible polypropylene sheet. The drying temperature in the early stage is 25°C for 10 minutes, and the drying temperature in the later stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com