Automatic production equipment and process of environment-friendly polycarboxylate superplasticizer

A technology of production equipment and water reducing agent, which is applied in chemical instruments and methods, grain processing, transportation and packaging, etc. It can solve the problems of conveyor belt corrosion, difficult to achieve filter matching, poor cleaning effect of conveyor belt, etc., to avoid mutual adhesion , The effect of reducing the accumulation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

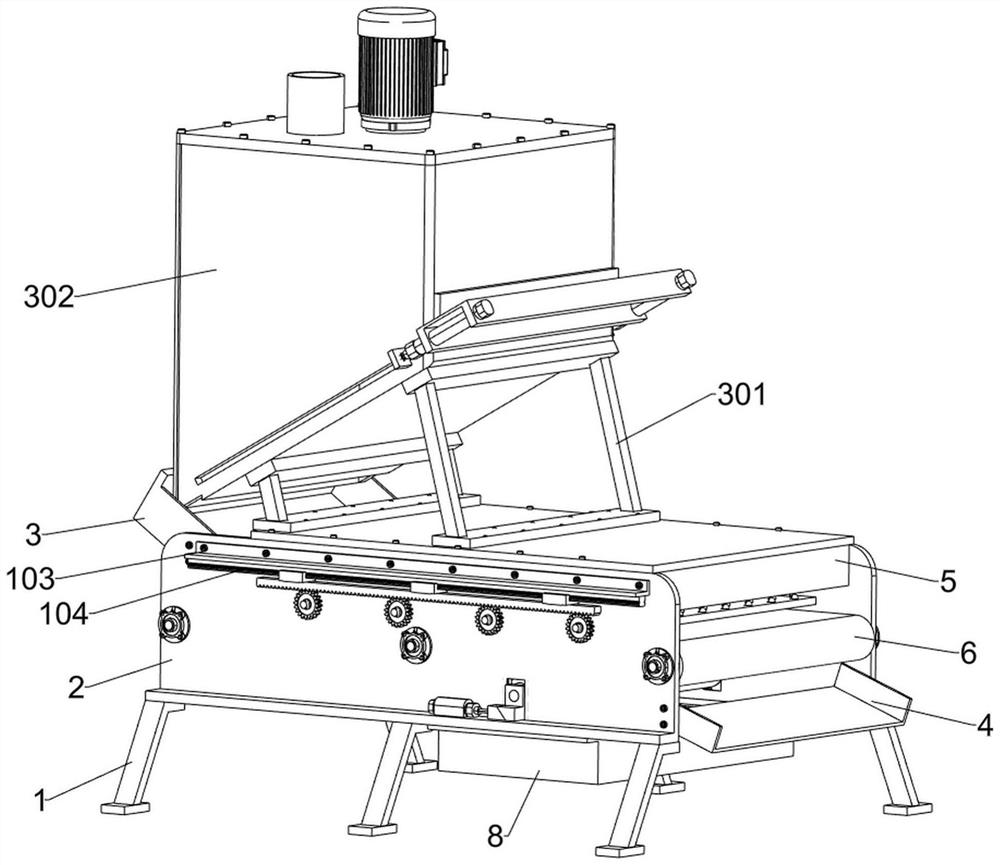

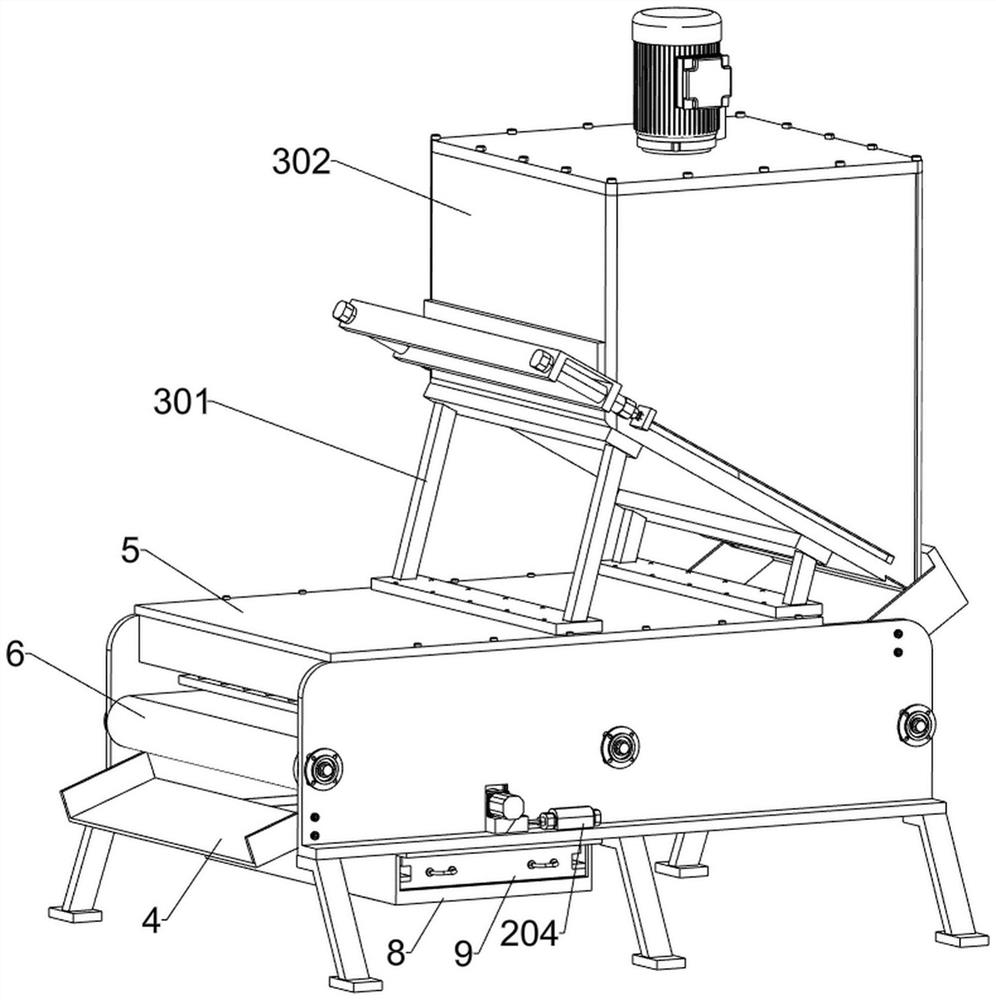

[0047] A kind of automatic production equipment of environment-friendly polycarboxylate water reducer, such as Figure 1-5 As shown, it includes a base 1, a first mounting plate 2, a cover plate 5, a transmission assembly 6, a second mounting plate 10, a screening system, a discrete system and a cleaning system; A first mounting plate 2; a first mounting plate 2 is fixed on the upper surface of the three bases 1 at the rear; a cover plate 5 is connected to the upper surface of the two first mounting plates 2; a screen is connected to the left part of the upper surface of the cover plate 5 system; the middle of the opposite sides of the two first mounting plates 2 is connected to the transmission assembly 6; the bottom right side of the two first mounting plates 2 is fixedly connected to the second mounting plate 10; Discrete system, and the discrete system is located above the transmission assembly 6; a cleaning system is connected between the opposite sides of the two first i...

Embodiment 2

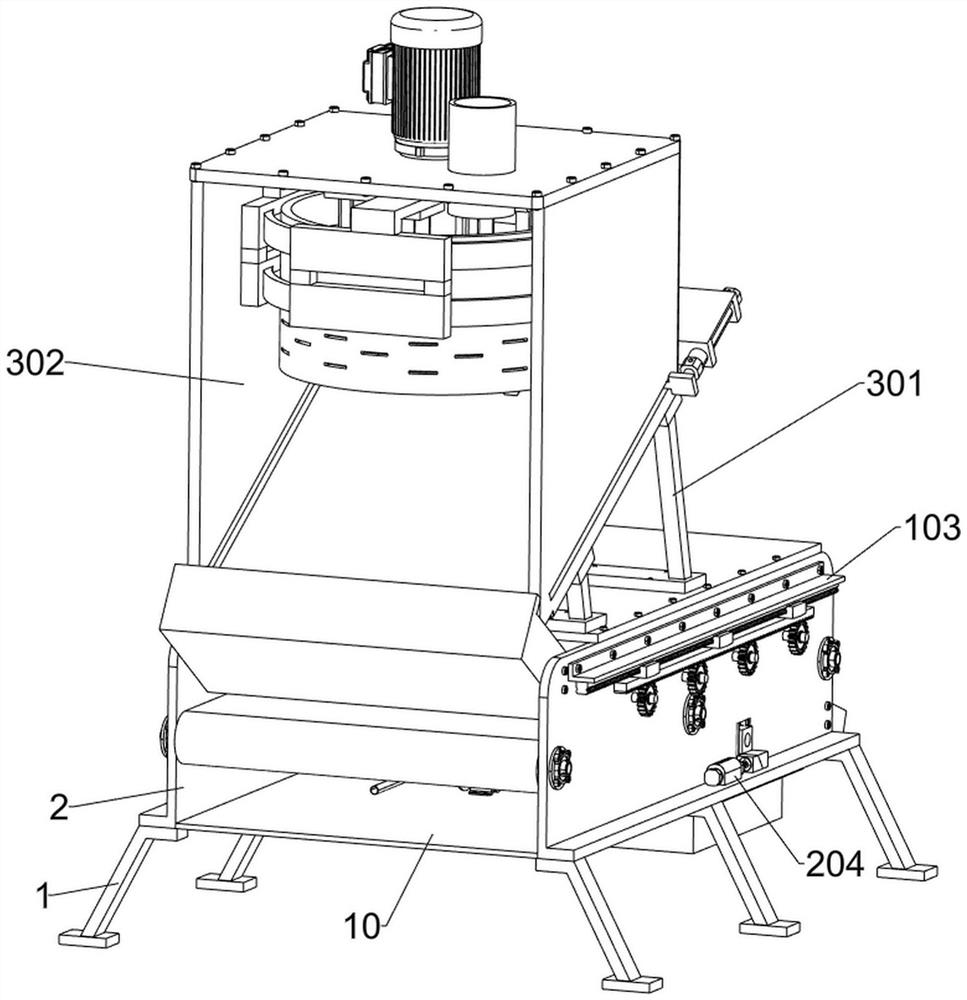

[0052] On the basis of Example 1, such as figure 1 and Figure 6-8 As shown, the screening system includes a support frame 301, an installation box 302, a side plate 303, a top plate 304, a limit block 305, a first fixed plate 306, a separation rod 307, a screening box 308, an annular plate 309, a second servo Motor 3010, connecting shaft 3011, second fixed plate 3012, second electric push rod 3013, push plate 3014 and separation teeth 3015; two support frames 301 are connected by bolts on the upper surface of cover plate 5, and the right support frame 301 is higher than The support frame 301 on the left; the upper part of the two support frames 301 is fixedly connected with the installation box 302; the left part of the installation box 302 is bolted to the side plate 303; A limit block 305; a limit block 305 is affixed to the right part of the side plate 303; four limit blocks 305 are in the same horizontal plane, and are evenly distributed in the circumferential direction;...

Embodiment 3

[0058] On the basis of Example 2, such as figure 1 , Figure 4-5 and Figure 9 , as shown, the discrete system includes a bulk plate 101, a spur gear 102, a third mounting plate 103, an electric slide rail 104, an electric slider 105 and a rack 106; the middle parts of the two first mounting plates 2 are rotationally connected with Four bulk material plates 101; each of the four bulk material plates 101 fronts is fixedly connected with a flat gear 102; the front side of the first mounting plate 2 in the front is welded with a third mounting plate 103; the bottom of the third mounting plate 103 is bolted to a Electric slide rail 104; three electric sliders 105 are fixedly connected to the electric slide rail 104; racks 106 are fixedly connected to the three electric sliders 105; four spur gears 102 are all engaged with the racks 106.

[0059] A plurality of leakage holes are opened on the bulk material plate 101, and a quarter spherical discrete block is welded above each lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com