Additive and subtractive double-station synchronous machining method and device for spiral pipe type components

A technology of simultaneous processing, adding and subtracting materials, applied in additive processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced transmission and processing accuracy, increased maintenance costs, low processing efficiency, etc., to shorten the processing process. and production cycle, saving man-hours and energy consumption, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

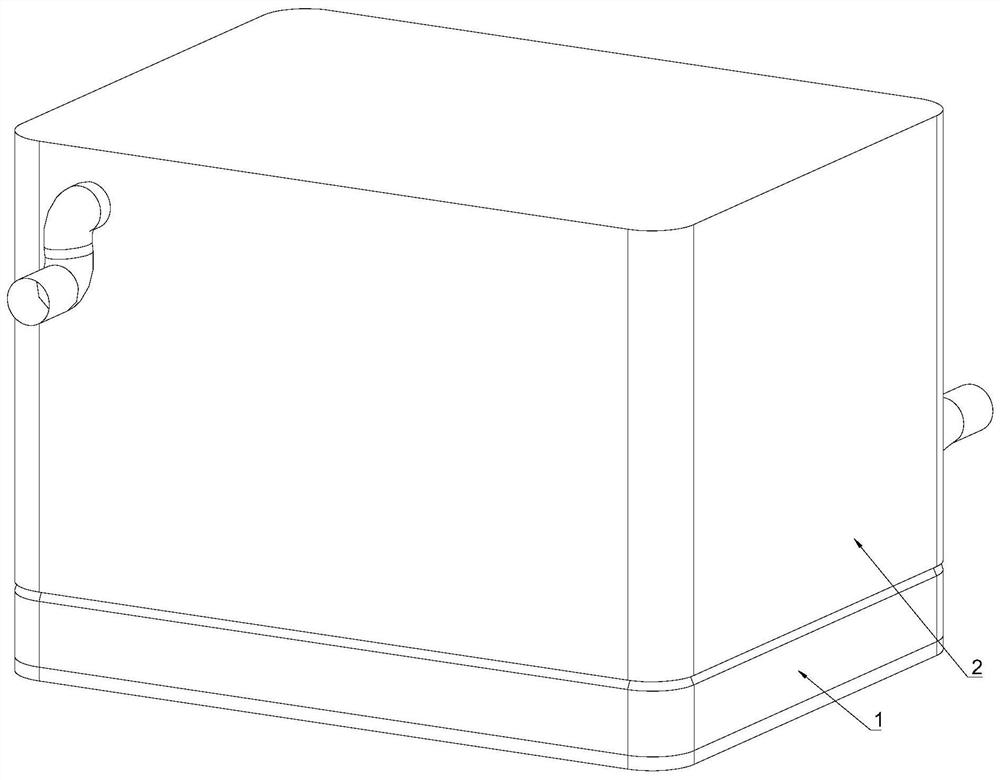

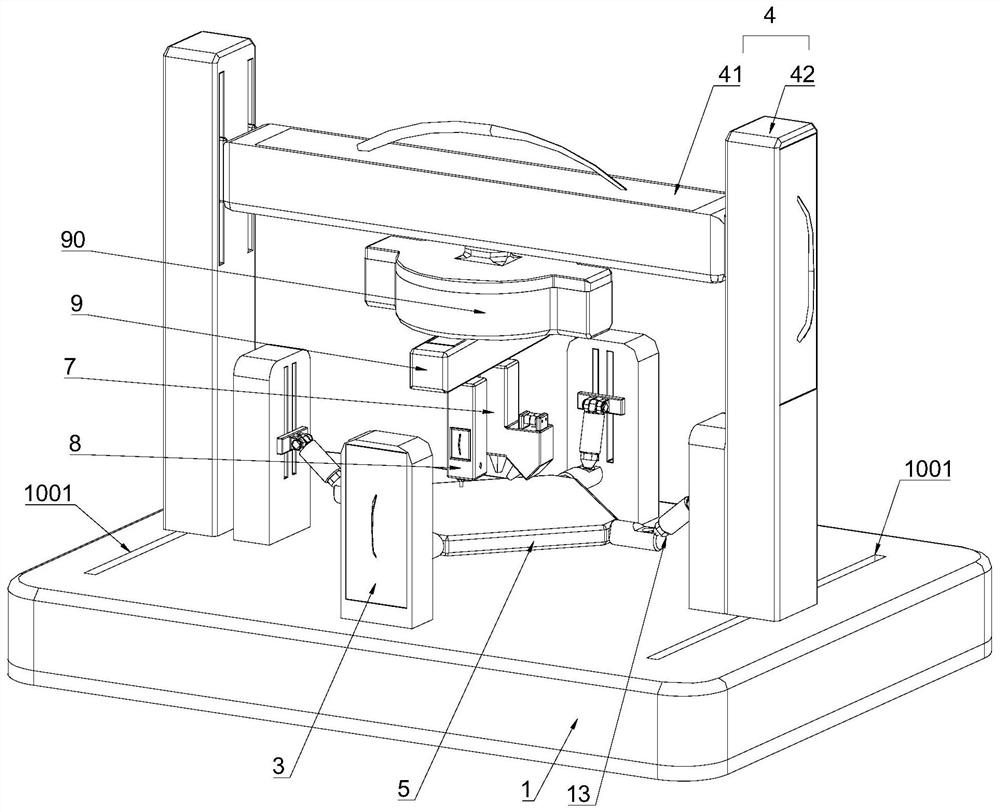

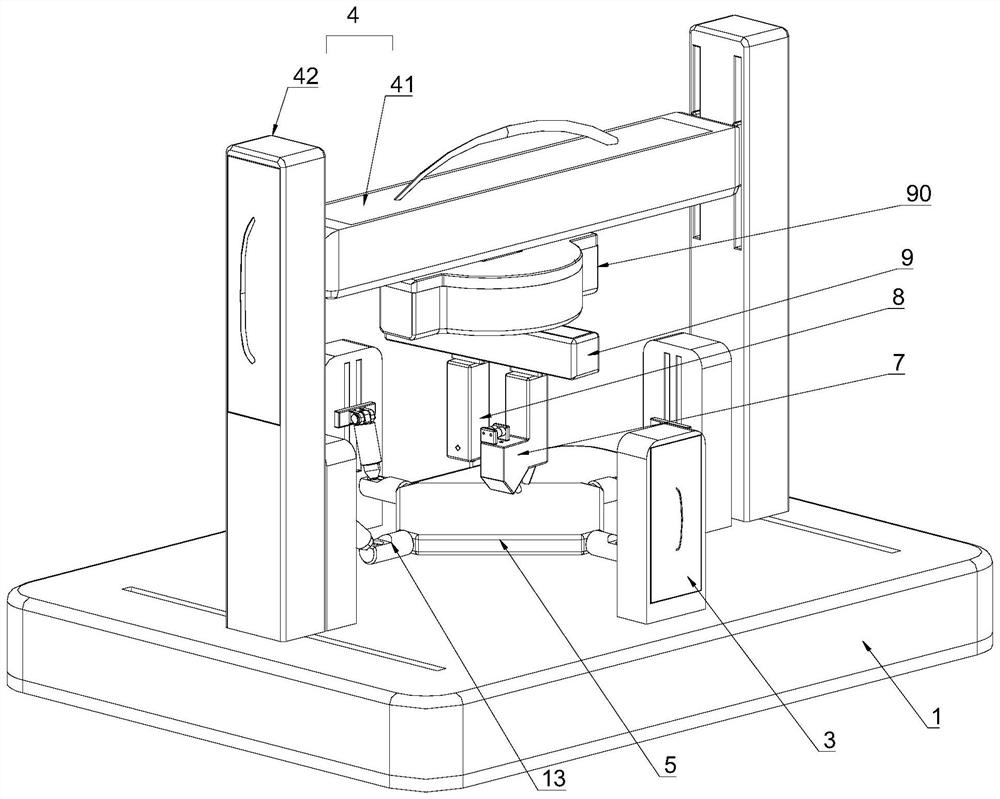

[0069] like Figures 1 to 27 As shown, a dual-station synchronous processing device for adding and subtracting materials of spiral tube components includes a fixed base 1, a first column 3, a gantry crane 4, a workbench 5, a rotating beam 90, a linkage beam 9, and a first connecting piece 13. The material addition module 7, the grinding and cutting module 8; the gantry crane 4 includes a gantry crane beam 41 and a gantry crane column 42, the gantry crane beam 41 is located above the workbench 5, and the gantry crane column 42 is located at both ends of the gantry crane beam 41 and fixed on the fixed base 1; The gantry crane beam 41 is provided with a first driving mechanism 43, and the rotating beam 90 moves horizontally relative to the gantry crane beam 41 driven by the first driving mechanism 43; the linkage beam 9 is arranged below the rotating beam 90, and the rotating beam 90 is provided with a second The driving mechanism 6, the second driving mechanism 6 is used to driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com