Express box

A technology of rotating rods and bottom plates, applied in the field of express boxes, can solve the problems of time-consuming, laborious, deformation, and difficult to disassemble, and achieve the effect of increasing the transportation volume and reducing the space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

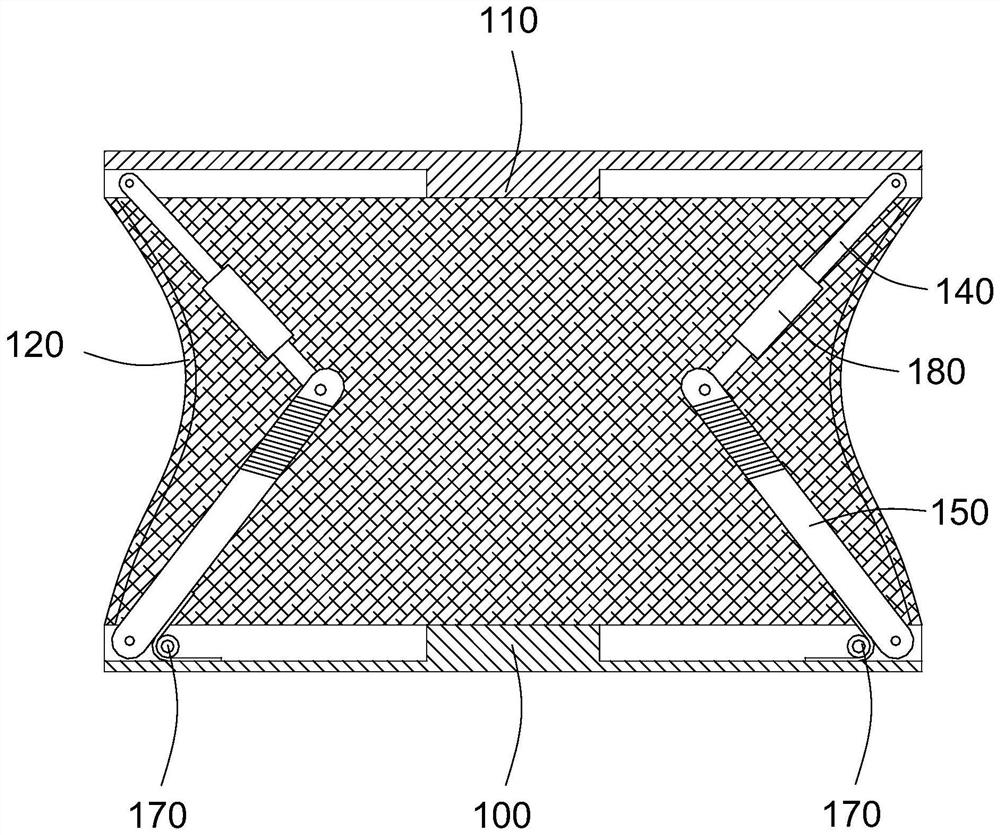

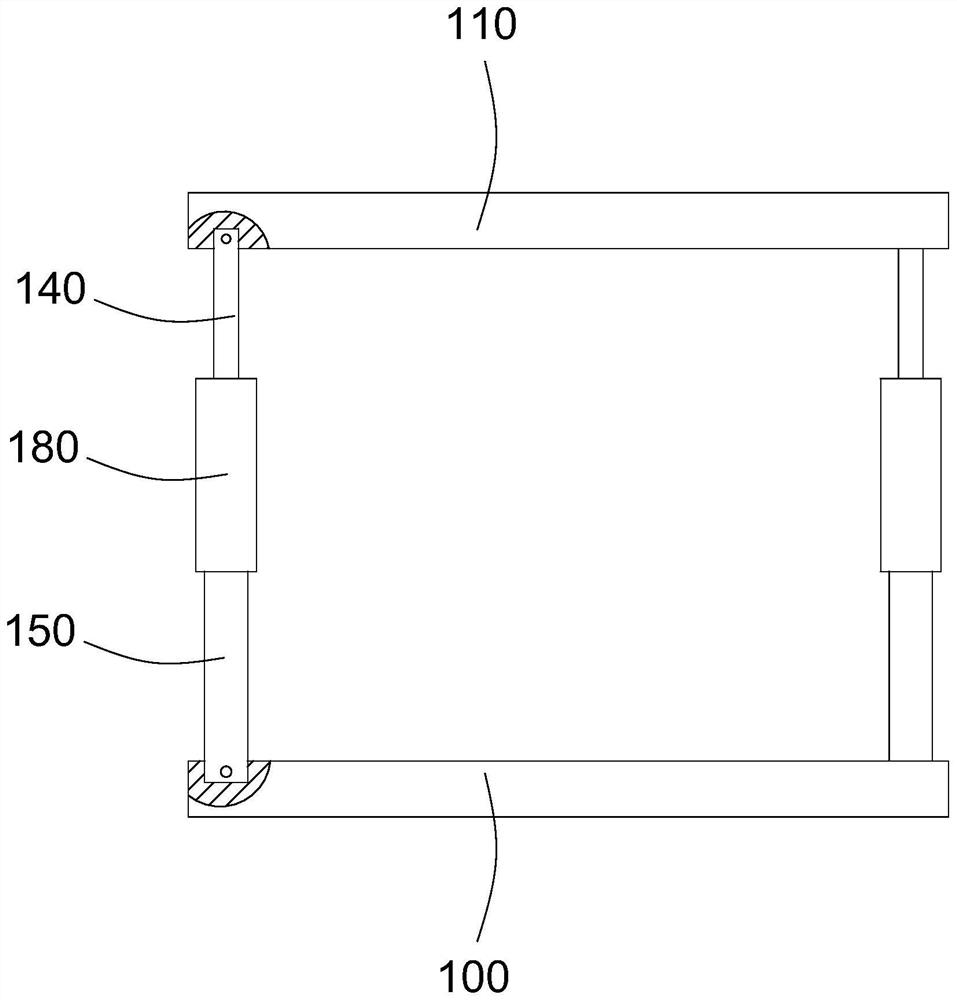

[0030] Please refer to Figure 1 to Figure 5 , the present embodiment provides a courier box, which includes a folding assembly, a protective cover 120, and a bottom plate 100 and a top plate 110 respectively connected to both sides of the protective cover 120, and the bottom plate 100 and the top plate 110 are respectively hinged to the two ends of the folding assembly.

[0031] In this embodiment, both the bottom plate 100 and the top plate 110 are made of TPU material. TPU has excellent properties of high tension, high tensile force, toughness and aging resistance, and is a mature environmental protection material. At present, TPU materials have been widely used in medical and health care, electronic appliances, industry and sports, etc. It has high strength, good toughness, wear resistance, cold resistance, oil resistance, water resistance, aging resistance, and weather resistance that other plastic materials cannot match. At the same time, it also has many excellent funct...

Embodiment 2

[0035] Please refer to figure 1 , figure 2 , Figure 6 , Figure 7 , the present embodiment proposes based on the technical solution of embodiment 1: the second rotating rod 150 is composed of a pair of symmetrically arranged support columns 160, the support columns 160 include a rotating part 161 and a support part 162 with a semicircular cross section, and the bottom plate 100 A mounting hole matching with the rotating part 161 is provided on the top, and a rotating hole 163 matching with the rotating shaft 130 is provided on the support part 162 .

[0036]In this embodiment, the second rotating rod 150 is composed of two symmetrically arranged supporting columns 160. The supporting columns 160 include a rotating part 161 and a supporting part 162 with a semicircular cross section. The rotating part 161 is arranged on the arc. One side wall is provided with a receiving groove on the base plate 100, and mounting holes are provided on the opposite side walls of the receivi...

Embodiment 3

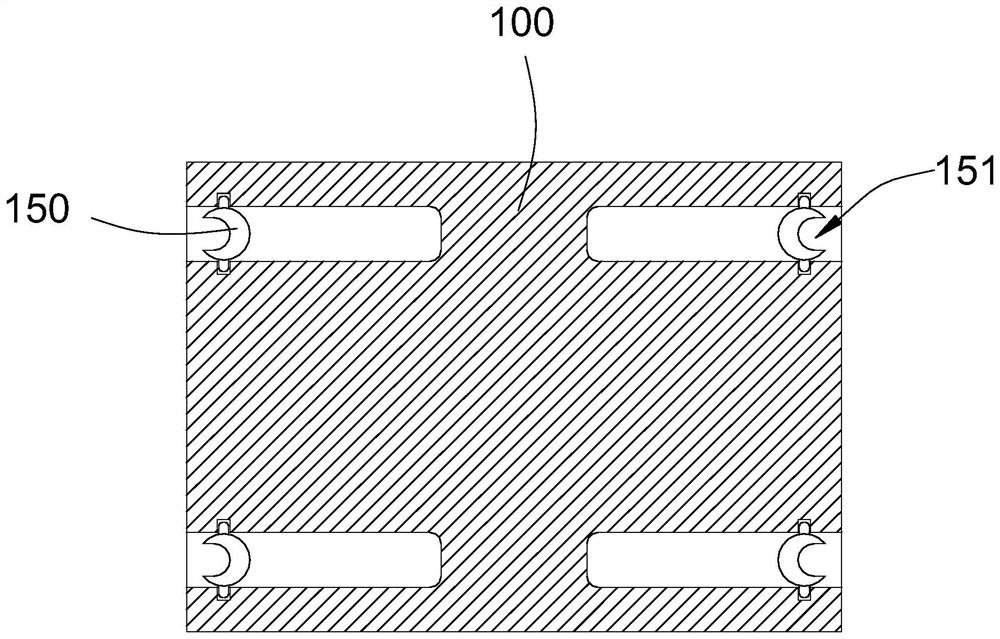

[0039] Please refer to image 3 , Figure 4 , this embodiment proposes based on the technical solution of Embodiment 1: the second rotating rod 150 is provided with a receiving groove 151 for hiding the first rotating rod 140, and the opening of the receiving groove 151 faces the side away from the inside of the box body.

[0040] In this embodiment, the second rotating rod 150 is cylindrical, and a semicircular receiving groove 151 is defined along the axial direction of the second rotating rod 150 , and the opening of the receiving groove 151 faces the side away from the inside of the box body. When rotating and storing, the first rotating rod 140 can be stored in the receiving groove 151, and at the same time, the entire folding assembly is bent into the box body, which not only ensures the aesthetics of the entire express box, but also further reduces the volume of the express box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com