Device for cross-line automatic logistics transfer of chopped products

A kind of animal and equipment technology, applied in the direction of conveyor objects, transportation and packaging, mechanical conveyors, etc., can solve the problems of high work intensity of employees, poor product appearance, overturning of raw silk trolleys, etc., to reduce safety hazards and automatic logistics transfer The equipment is stable and the effect of avoiding the rollover of the trolley

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

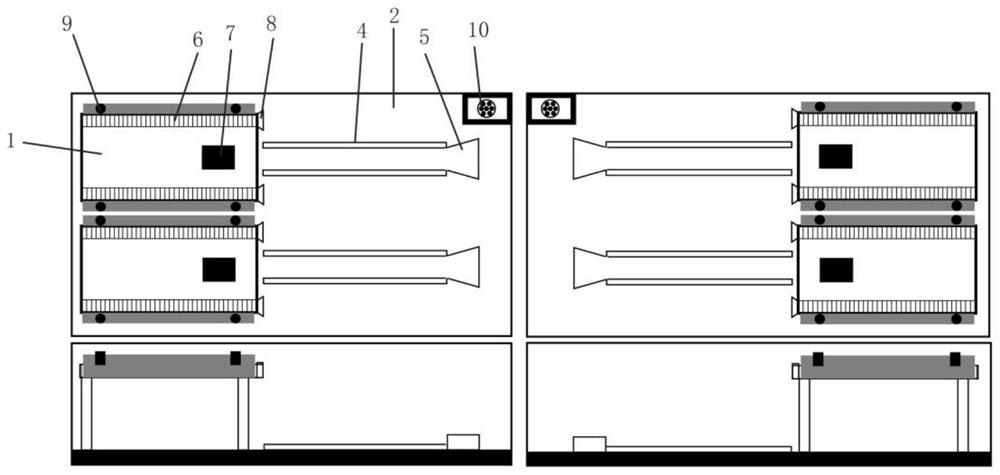

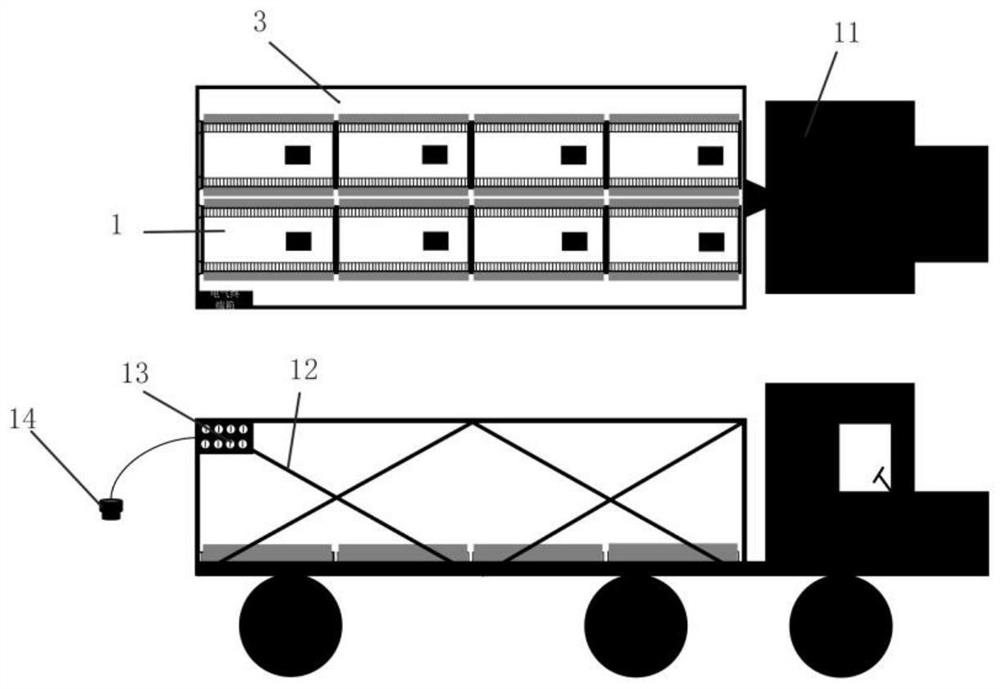

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0024] see Figure 1-2 .

[0025] The invention discloses a cross-line automatic logistics transfer equipment for chopped products, including a yarn loading / unloading system and an automatic logistics transfer equipment. The yarn loading / unloading system is composed of a plurality of independent raw silk trolleys 1 and a transfer platform 2 Each transfer platform is provided with a raw silk trolley transmission device; the transfer platform 2 is arranged in the bearing area 3 of the automatic logistics transfer equipment, and the transfer platform 2 is provided with a raw silk trolley sorting and guiding device.

[0026] The sorting and guiding device of the raw silk trolley is an automatic material transfer docking guide rail 4, and the raw silk trolley 1 is transported to the transfer platform 2 through the automatic material transfer docking guide rail.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com