Rubber composition for shoe sole, application of rubber composition, vulcanized rubber, and preparation method and application of vulcanized rubber

A rubber composition and a technology for the composition, applied in the rubber field, can solve the problems of low rubber strength and poor flexural resistance, and achieve the effects of high rubber strength and good flexural resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

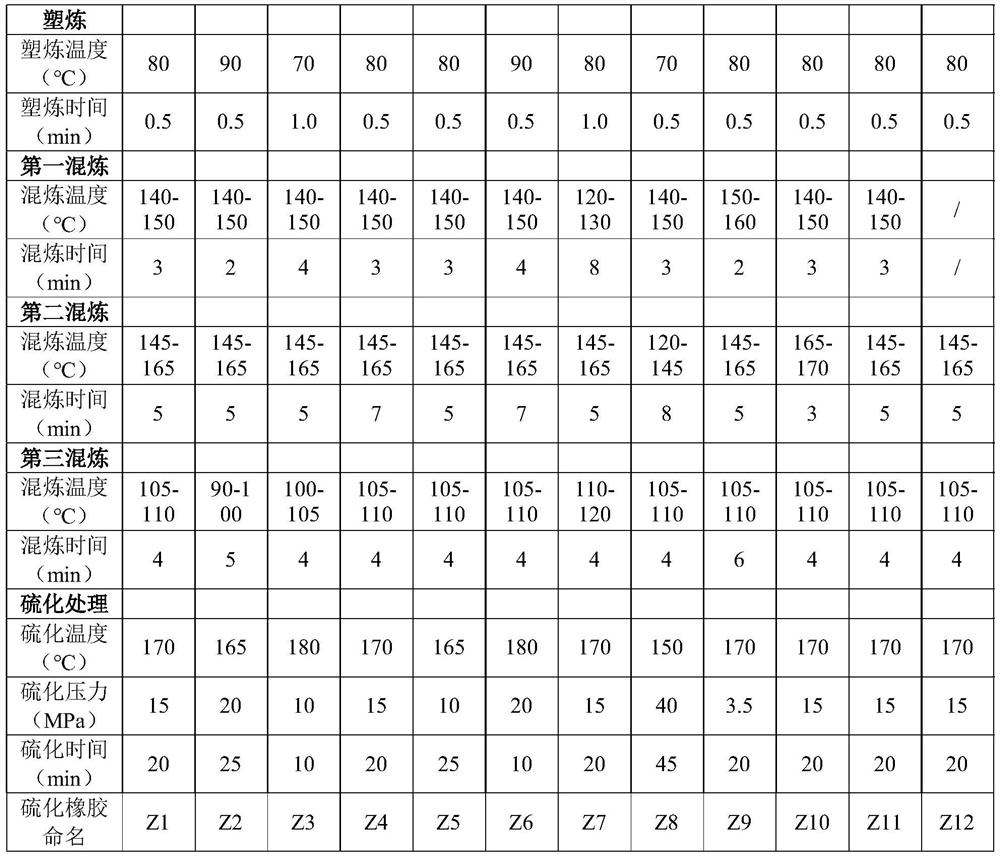

[0085] Preparation Example 1: Preparation of Vulcanized Rubber

[0086] First mixing:

[0087] Put the main rubber into the internal mixer, set the rotational speed of the internal mixer to 80rpm, and set the mastication temperature of the internal mixer to perform mastication to obtain the masticated rubber. Then, white carbon black, additives and surface modifiers are added into the internal mixer, the mixing temperature of the internal mixer is set, and the first mixing is performed with the masticated rubber to obtain the first mixed rubber.

[0088] Second mixing:

[0089] Lift the top pin of the internal mixer for the first mixing, carry out the second mixing with zinc methacrylate, hydrogenated terpene resin, activator, anti-aging agent, softener and the first mixing rubber, and deglue, Stand for 4h to obtain the second rubber compound.

[0090] The third mixing:

[0091] Put the aforementioned second compounded rubber in the internal mixer for mastication, set the ...

preparation example 12

[0095] Second mixing:

[0096] Put the main rubber into the internal mixer, set the rotational speed of the internal mixer to 80rpm, and set the mastication temperature of the internal mixer to perform mastication to obtain the masticated rubber. Then add white carbon black, additives, surface modifiers, zinc methacrylate, hydrogenated terpene resins, activators, anti-aging agents and softeners into the internal mixer, set the mixing temperature of the internal mixer, and plasticize The rubber is subjected to the second mixing to obtain the second mixed rubber.

[0097] The third mixing:

[0098] Put the aforementioned second compounded rubber in the internal mixer for mastication, set the speed of the internal mixer to 80rpm, and the initial plasticating temperature of the internal mixer to 40°C, after the second compounded rubber is masticated for 1min, add The vulcanizing agent and auxiliary crosslinking agent are mixed for the third time to obtain the final compound rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com