Hydrocracking method for producing aviation kerosene

A technology of hydrocracking and jet fuel, which is applied in the field of oil refining, can solve the problems of limited application fields, and achieve the effect of simple process, low operating cost and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

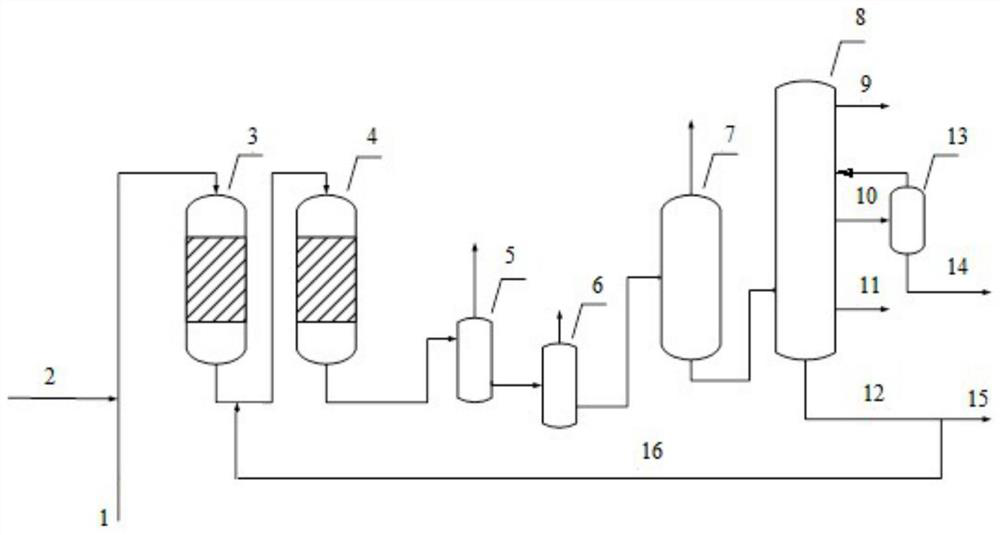

Method used

Image

Examples

Embodiment 1

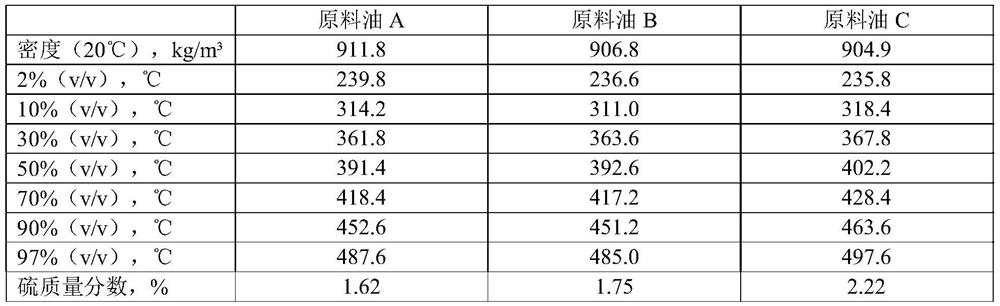

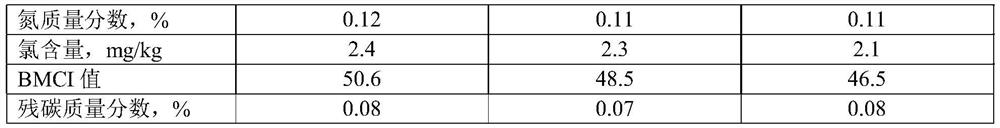

[0075] The raw material oil A shown in Table 1 and hydrogen are introduced into the hydrofinishing reaction zone containing the hydrofinishing catalyst, the hydrocracking catalyst and the post-refining catalyst hydrocracking reaction zone to react, and the reaction conditions are as shown in Table 2; Then the reaction effluent of the hydrocracking reaction zone is introduced into a high-pressure separator and a low-pressure separator successively for gas-liquid separation to obtain a liquid phase product, and the liquid phase product is successively introduced into a hydrogen sulfide stripping tower and a fractionating tower, Carry out fractionation in fractionating tower, obtain naphtha fraction, kerosene fraction, diesel oil fraction and tail oil fraction (the cut point of described naphtha fraction and described kerosene fraction is 155 ℃; The cut point of described kerosene fraction and described diesel oil fraction The cut point is 250°C; the cut point of the diesel fracti...

Embodiment 2

[0077] The raw material oil A shown in Table 1 was used, and the process was carried out in the same manner as in Example 1, except that the process conditions were changed as shown in Table 2, and the tail oil recycling ratio was 64.3% by weight. The yields of product naphtha fraction, product diesel fraction and tail oil product are shown in Table 3, and the properties of jet fuel products are shown in Table 4.

Embodiment 3

[0081] The raw material oil B shown in Table 1 was used, and the process was carried out in the same manner as in Example 1, except that the process conditions were changed as shown in Table 2, and the tail oil recycling ratio was 32.4% by weight. The yields of product naphtha fraction, product diesel fraction and tail oil product are shown in Table 3, and the properties of aviation fuel products are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com