Preparation method of high-strength corrosion-resistant high-toughness Al-Mg-Zn-Ag (-Cu) aluminum alloy

An aluminum alloy and corrosion-resistant technology, applied in the field of non-ferrous metal preparation, can solve the problems of reducing the intergranular corrosion resistance of the alloy, amplifying the PLC effect of the alloy, and complicating the alloy manufacturing, so as to improve the elongation, strength and intergranular corrosion resistance. , the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Melt and cast according to the 1# alloy composition in Table 1; the ingot is heated from room temperature to 410°C with the furnace at a rate of 30°C / h, kept at 8h, and then raised to 470°C at 30°C / h, kept at room temperature for 24h, and then cooled to room temperature ;After homogenizing annealing, surface milling and hot rolling, the hot rolling start temperature is 420°C, the total reduction is >90%, and the thickness after rolling is 6mm; the hot rolled plate is cold rolled, and the 6mm hot rolled plate is first cold rolled to 5mm, then recrystallized and annealed at 365°C for 75min, and then cold-rolled to 2.5mm; the cold-rolled sheet was solution treated in an air furnace at 475°C / 30min, then rapidly quenched in water at 25°C, and then 90°C / 26h+140°C / 20h double-stage aging treatment. According to "GB / T228.1-2010", samples were taken from the aged plate for tensile test, and the test results are shown in Table 2.

Embodiment 2

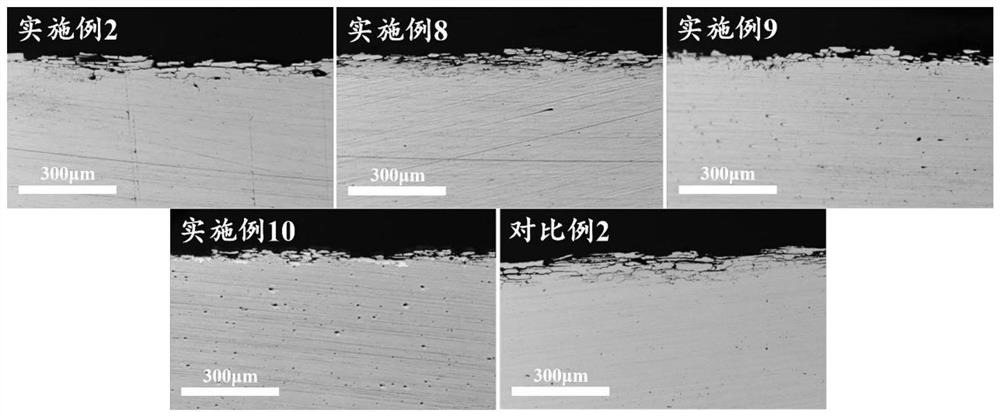

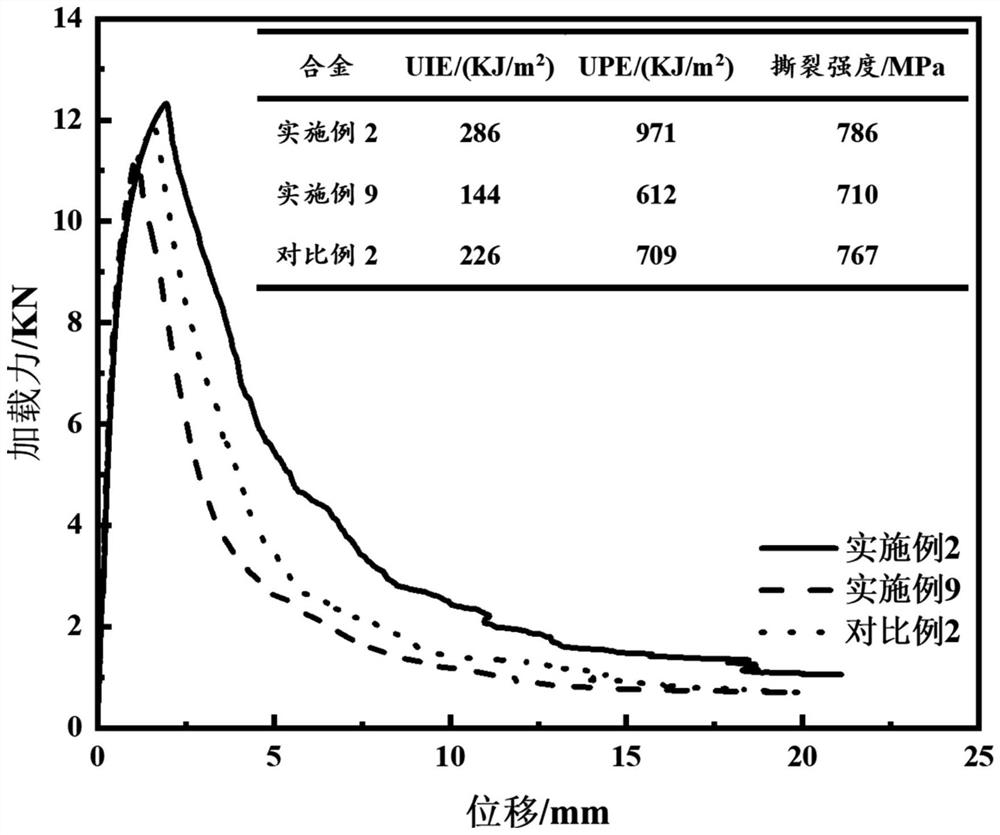

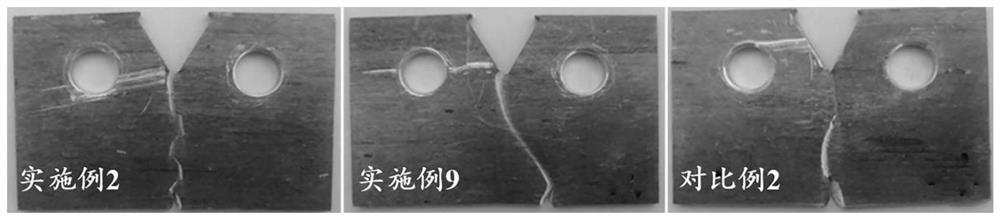

[0040] Melting and casting according to the 2# alloy composition in Table 1; the ingot was heated from room temperature to 420°C with the furnace at a rate of 30°C / h, kept at 8h, and then raised to 470°C at 30°C / h, kept at room temperature for 24h, and then cooled to room temperature ;After homogenizing annealing, surface milling and hot rolling, the hot rolling start temperature is 430°C, the total reduction is >90%, and the thickness after rolling is 6mm; the hot rolled plate is cold rolled, and the 6mm hot rolled plate is first cold rolled to 5mm, then recrystallized and annealed at 375°C for 75min, and then cold-rolled to 2.5mm; the cold-rolled sheet was solution treated in an air furnace at 480°C / 20min, then rapidly quenched in water at 25°C, and then 90°C / 24h+140°C / 18h double-stage aging treatment. According to "GB / T228.1-2010" and "ASTM B871", samples were taken from the aged plate for tensile and tear tests respectively, and the intergranular Corrosion experiment, re...

Embodiment 3

[0042] Melting and casting according to the 3# alloy composition in Table 1; the ingot is heated from room temperature to 420°C with the furnace at a rate of 30°C / h, kept at 8h, and then raised to 470°C at 30°C / h, kept at room temperature for 24h, and then cooled to room temperature ;After homogenizing annealing, surface milling and hot rolling, the hot rolling start temperature is 430°C, the total reduction is >90%, and the thickness after rolling is 6mm; the hot rolled plate is cold rolled, and the 6mm hot rolled plate is first cold rolled to 5mm, then recrystallized and annealed at 375°C for 75min, and then cold-rolled to 2.5mm; the cold-rolled sheet was solution treated in an air furnace at 480°C / 20min, then rapidly quenched in water at 25°C, and then 90°C / 24h+140°C / 18h double-stage aging treatment. According to "GB / T228.1-2010", samples were taken from the aged plate for tensile test, and the test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com