Abdominal pad processing device and processing technology thereof

A processing device and abdominal pad technology, which is applied to clothing collection devices, textiles, papermaking, sewing equipment, etc., can solve the problems of skewed cutting edges, irregular stacking, and low hemming efficiency, and achieve simple processing steps, The effect of shortening the interval time and increasing the production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

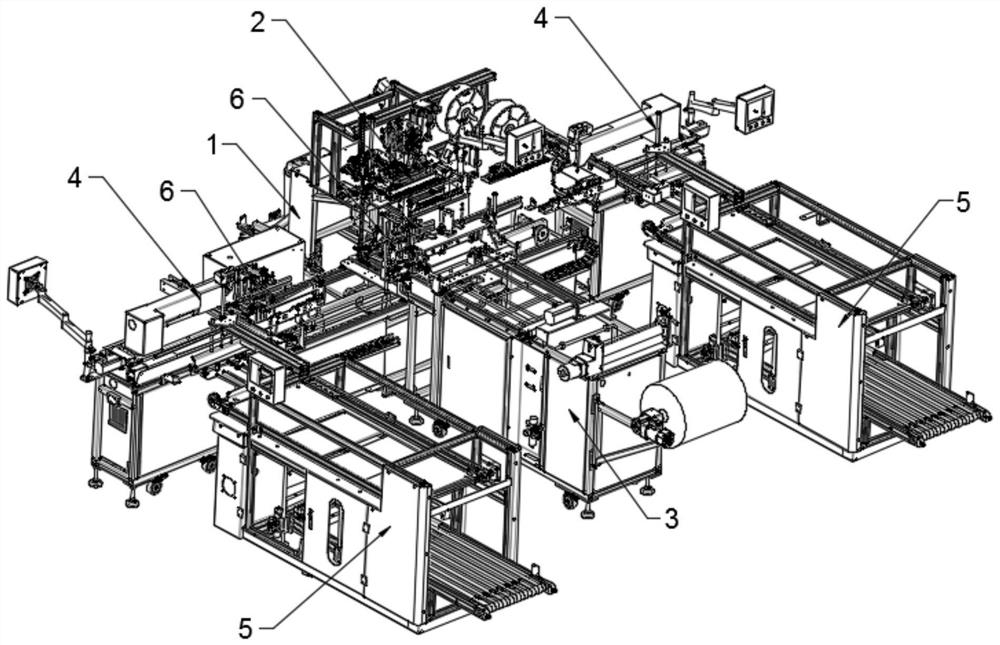

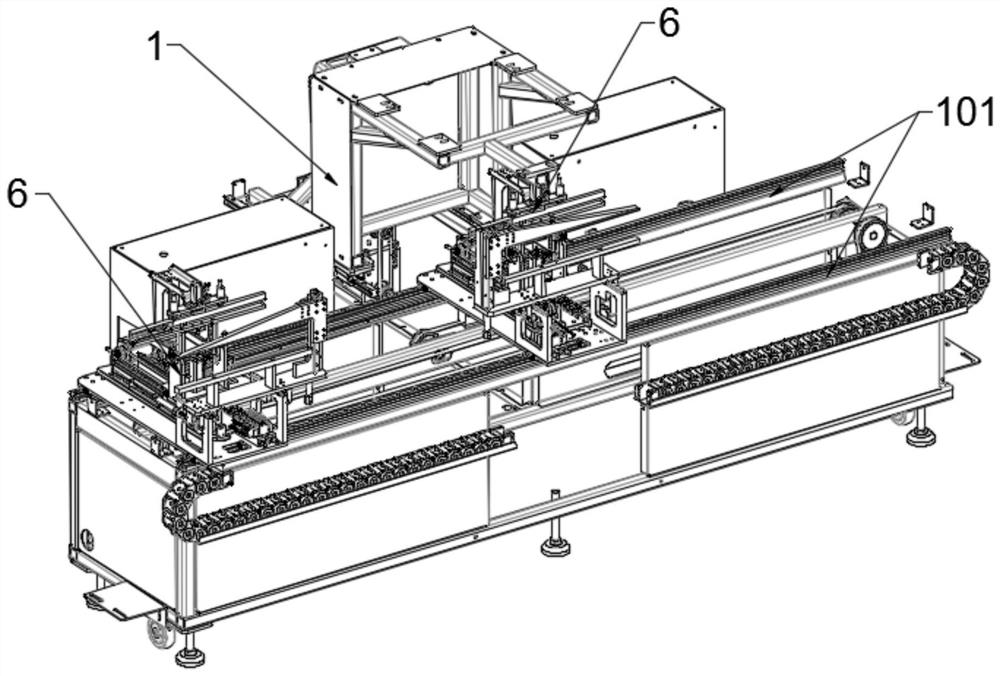

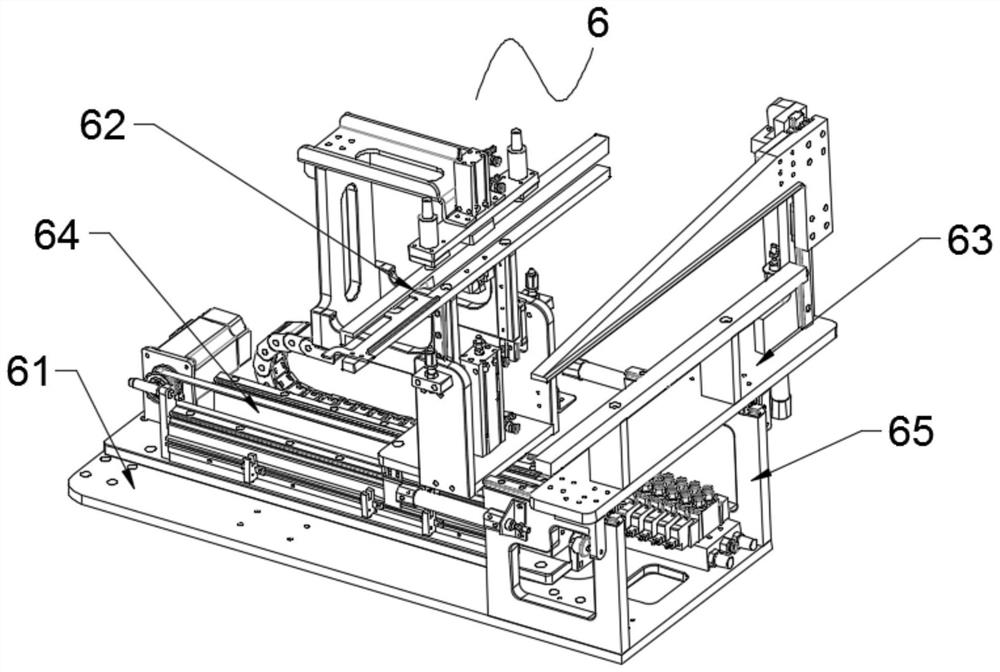

[0054] refer to figure 1 As shown, this embodiment provides an abdominal pad processing device, including a main processing chassis 1, a label feeding processing mechanism 2, a gauze feeding mechanism 3, a sewing mechanism 4 and a receiving mechanism 5; The mechanism 2 is used to weld the cotton cloth and the barium sheet to form the label, the gauze feeding mechanism 3 is used to feed the gauze and fold it in half to form the body of the abdominal pad, and the sewing mechanism 4 is used to sew the body of the abdominal pad and the label to sew the body. Made into a belly pad. The top of the main processing chassis 1 is fixedly provided with a tape feeding and processing mechanism 2, a processing induction guide rail 101 is fixedly installed on the main processing base frame 1, and two sets of transfer components 6 are slidably arranged on the processing induction guide rail 1; the sewing mechanism 4 Two are provided and are respectively arranged at both ends of the main proc...

Embodiment 2

[0080] The present embodiment discloses an abdominal pad processing technology, which adopts the device of Embodiment 1 for processing and use, and includes the following steps:

[0081] Step 1: The gauze is fed into the first transfer component 6 through the gauze feeding mechanism 3, and the gauze is folded by the gauze feeding structure 3 and then clamped and fixed by the transfer component 6 to form the main body of the abdominal pad, and the gauze is The cutting knife of the feeding mechanism 3 cuts the gauze;

[0082] Step 2: The cotton cloth and the barium sheet are processed by the tape feeding processing mechanism 2 and welded together to form a tape. The mobile manipulator of the tape feeding processing mechanism 2 transfers the tape to the transfer component 6 and attaches it to the abdominal pad. After the main body is combined, it is clamped and fixed;

[0083] Step 3: The first transfer component 6 moves along the processing induction guide rail to transfer the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com