Oil displacement type slickwater well washing blockage removal construction method

A construction method and slick water technology, which can be used in flushing wellbore, earthwork drilling, wellbore/well components, etc., can solve problems such as secondary pollution of formations, reduce pollution damage, solve secondary pollution, and improve oil well production and the effect of oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

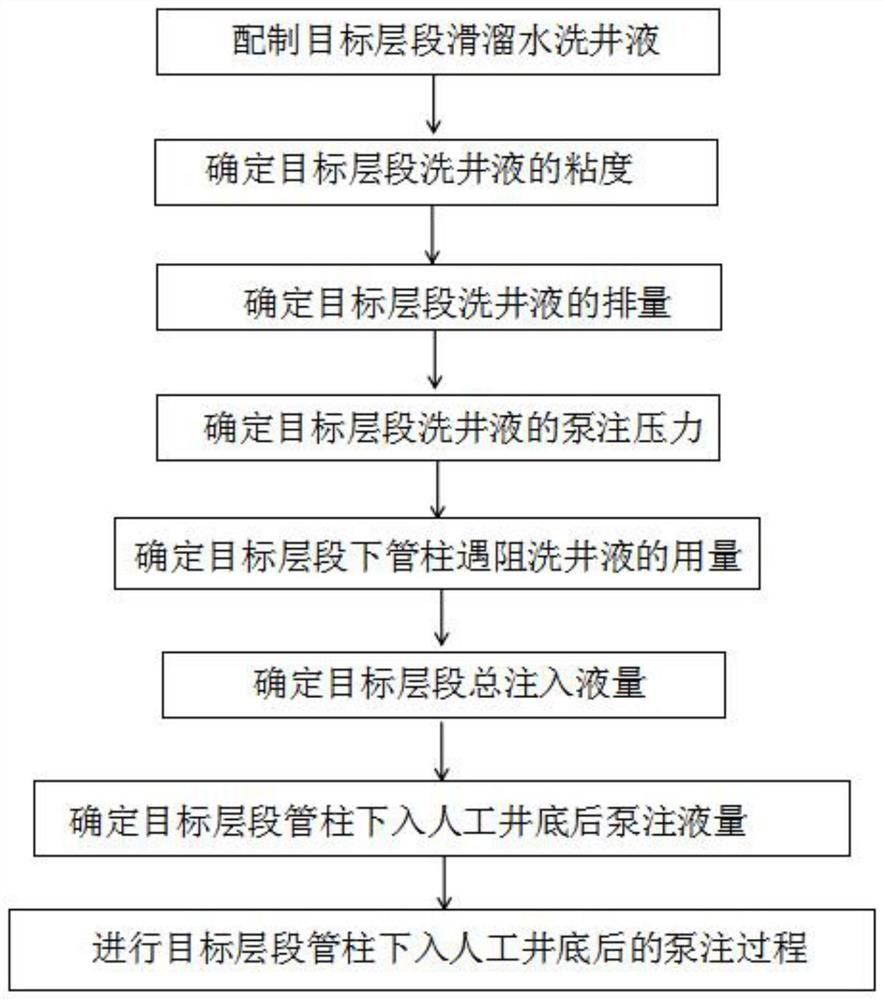

[0028] The oil displacement type slick water washing well plugging removal construction method of the present invention, refer to figure 1 , including the following steps:

[0029] Step 1, determine the formulation of the slick water washing fluid in the target interval; specifically:

[0030] The composition and proportion of the well flushing fluid are: 0.1% drag reducer + 0.2% multifunctional additive + 0.05% bactericide + 0.5% HE-BIO biological oil displacement agent + 99.15% water.

[0031] Among them, the role of JHFR-2 drag reducer is mainly to prevent the transition from laminar flow to turbulent flow or to reduce the degree of turbulent flow. It is characterized by self-reflux, no residue, and is an environmentally friendly and low-damage nano-slippery water system.

[0032] JHFD-2 multifunctional additive has anti-swelling effect....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com