Intelligent pressure regulating pump station

An intelligent, pumping station technology that can be used in pumps, pump components, pump devices, etc., to solve problems such as component wetting, component damage, and water waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

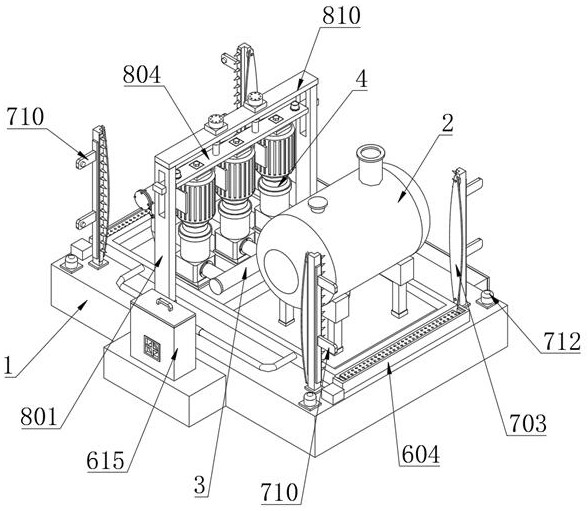

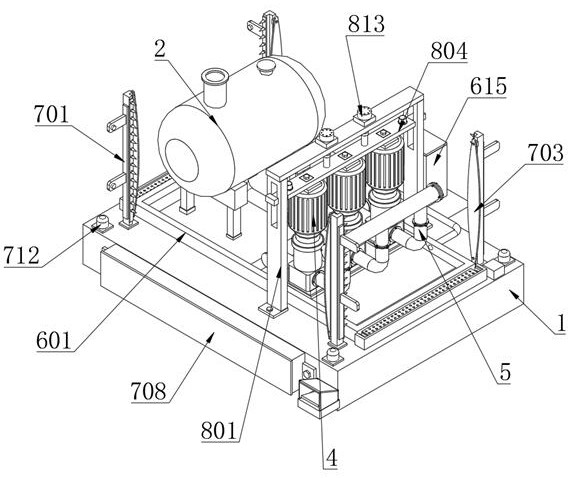

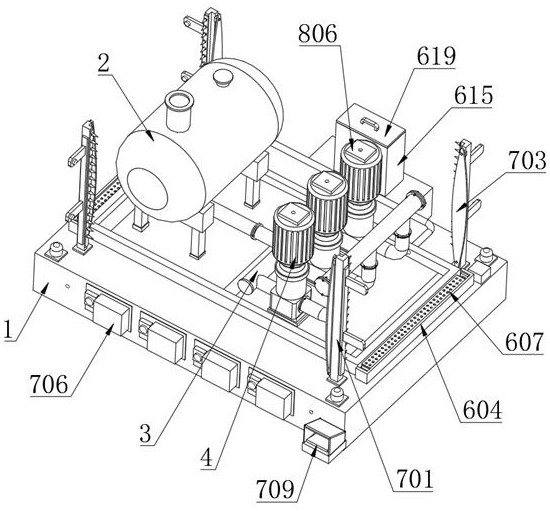

[0037] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, an intelligent pressure regulating pump station, including a base 1, a steady flow tank 2 is fixedly installed on one end of the top of the base 1, and a water delivery pipe is fixedly connected to the bottom end of the base 1 3. The top of the base 1 is located on one side of the steady flow tank 2, and the water pump 4 is fixedly installed equidistantly. The number of the water pump 4 is three. A drainage pipe 5 is connected, and the top of the base 1 is located at the position below the steady flow tank 2 and the water pump 4. A convenient water leakage detection mechanism 6 is provided to monitor the water leakage of the water pump 4 and the pipeline, and the leaked water is absorbed by the expansive soil block 610. Make its volume increase, and the extrusion block 611 touches the contact sensor 612, and the water leakage situation can be fed back in time;

[0038] The conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com