Method, device and system for on-line measurement of flue gas flow velocity of kiln smoke exhaust pipeline

A technology of flue gas flow rate and exhaust pipes, which is applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve the problems that the flue gas flow rate of kiln exhaust pipes cannot be measured online and affects the efficiency of heat recovery systems, etc., to achieve reduction Reduce energy consumption, improve accuracy, and improve recycling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

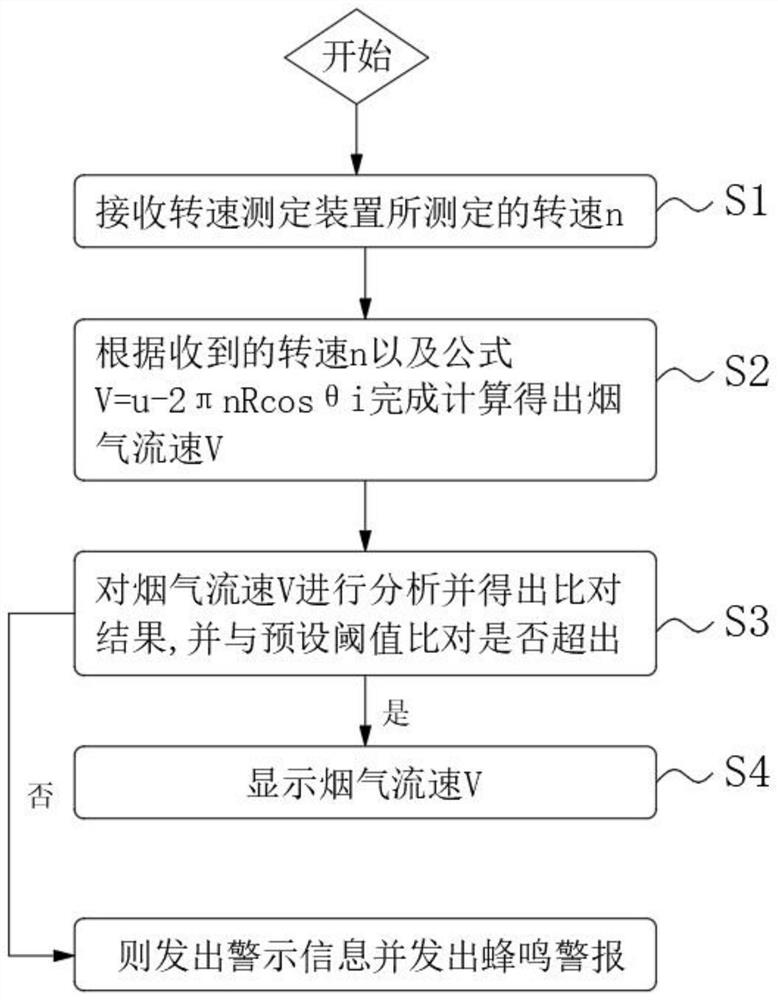

[0053] Please refer to Figure 1-3 , the present embodiment shows an online method for measuring the flue gas flow rate of a kiln exhaust pipe, comprising the following steps:

[0054] Step S1, receiving the rotational speed n measured by the rotational speed measuring device, the rotational speed n is recorded by the rotational speed sensor within the time period every 3-5 minutes, and measured once every 5-10 minutes;

[0055] Step S2, calculate the flue gas flow rate V according to the received rotational speed n, and send it to the terminal. The flue gas flow rate V is obtained according to the calculation formula:

[0056] V=u-2πnRcosθi;

[0057] In the formula, u is assumed to be a constant value of the flue gas flow rate in the flue, n is the rotational speed of the smoke cup, R is the radius from the smoke cup to the rotation axis, and iθ is the intersection angle between the smoke and the normal direction inside the smoke cup;

[0058] Step S3: Analyze the smoke flo...

Embodiment 2

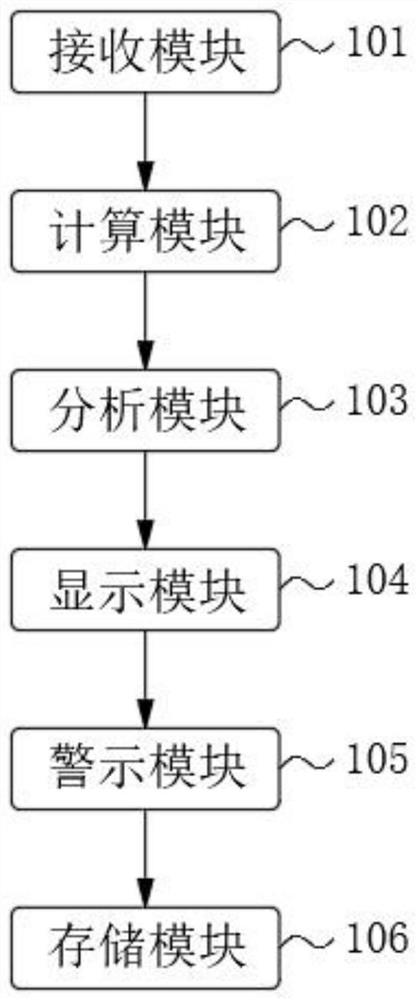

[0075] Please refer to Figure 1-4 , the present embodiment shows an online method for measuring the flue gas flow rate of a kiln exhaust pipe, comprising the following steps:

[0076] Step S1, receiving the rotational speed n measured by the rotational speed measuring device, the rotational speed n is recorded by the rotational speed sensor within the time period every 3-5 minutes, and measured once every 5-10 minutes;

[0077] Step S2, calculate the flue gas flow rate V according to the received rotational speed n, and send it to the terminal. The flue gas flow rate V is obtained according to the calculation formula:

[0078] V=u-2πnRcosθi;

[0079] In the formula, u is assumed to be a constant value of the flue gas flow rate in the flue, n is the rotational speed of the cup, R is the radius from the cup to the rotation axis, and iθ is the angle between the smoke and the normal direction inside the cup;

[0080] Step S3, analyzing the flue gas flow rate V and obtaining the...

Embodiment 3

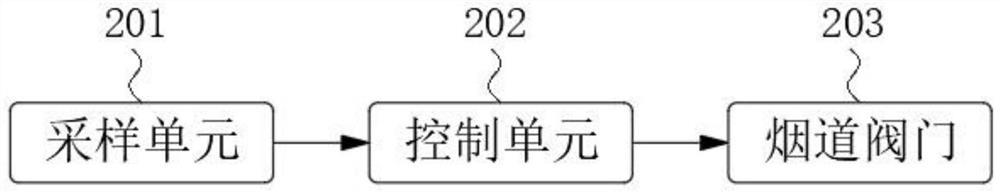

[0101] Please refer to Figure 5-8 , this embodiment shows a rotating speed measuring device used in the flue of a kiln, including position measuring points set in the flue 20, the number of position measuring points is set to four, and the four position measuring points are respectively set in the flue On the four endpoints of the rectangular boundary formed in the duct 20, the measuring point is used to install the rotational speed measuring device, and the measuring point is set on the vertical section in the flue 20;

[0102] The rotating speed measurement device includes a sampling smoke inlet housing 2011 fixed on the measuring point, a rotating shaft 2012 is installed in the sampling smoke inlet housing 2011, and a plurality of equidistantly distributed blades 2014 are arranged on the outer surface of the rotating shaft 2012 , a tobacco cup 2015 is provided on the leaf plate 2014;

[0103] The rotational speed measuring device further includes a rotational speed sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com