Metal bar surface anti-rust oil smearing device

A metal bar, anti-rust oil technology, applied in the device, coating and other directions of coating liquid on the surface, can solve the problems of dripping on the ground, rust on the surface of the bar, slow efficiency, etc., to reduce consumption, dismantle Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

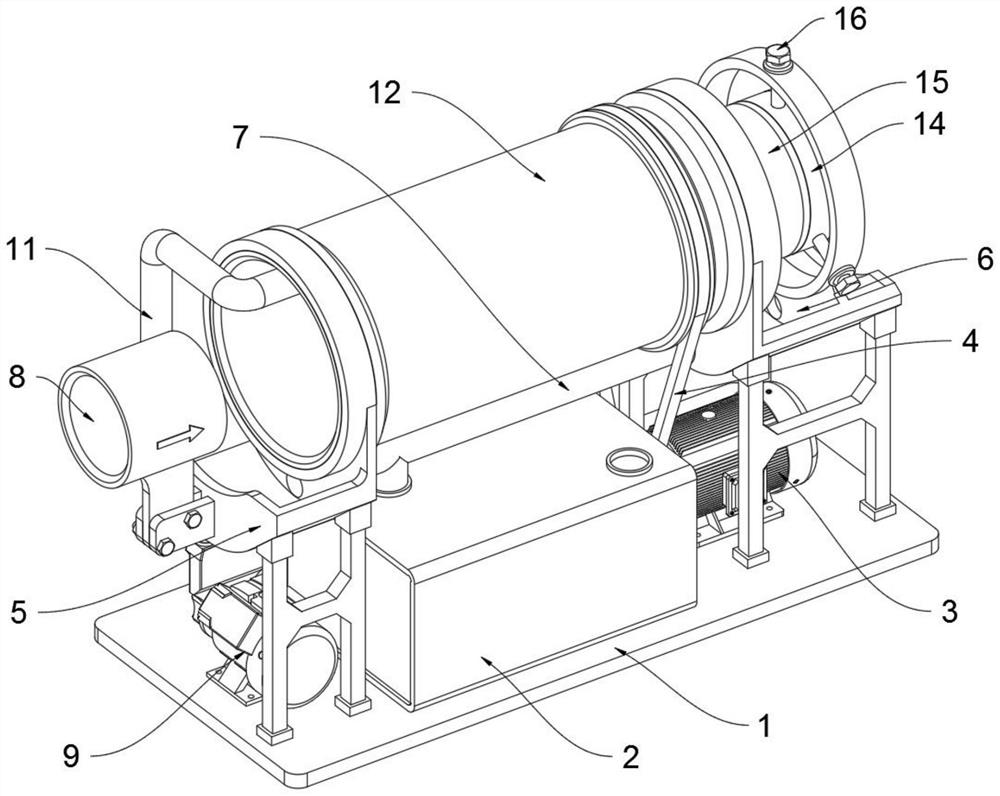

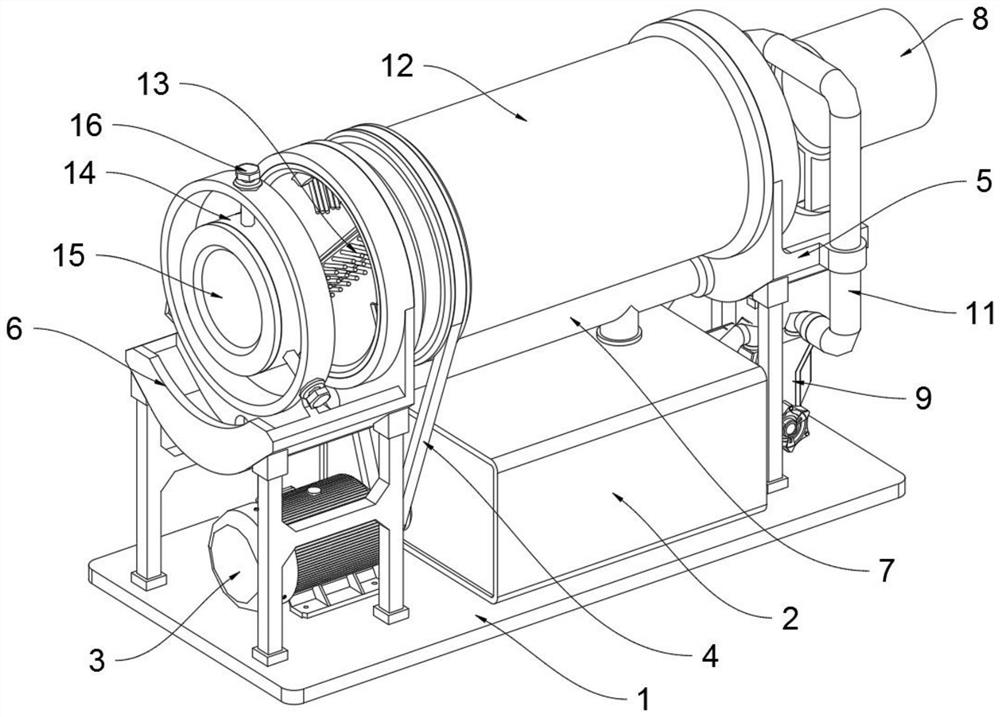

[0044] as attached figure 1 to attach Figure 7 Shown:

[0045] The present invention provides a device for applying anti-rust oil on the surface of metal bars, which includes a base 1, a front oil collection tank 5, a rear oil collection tank 6, a collection pipe 7, a guide support pipe 8 and a drum 12;

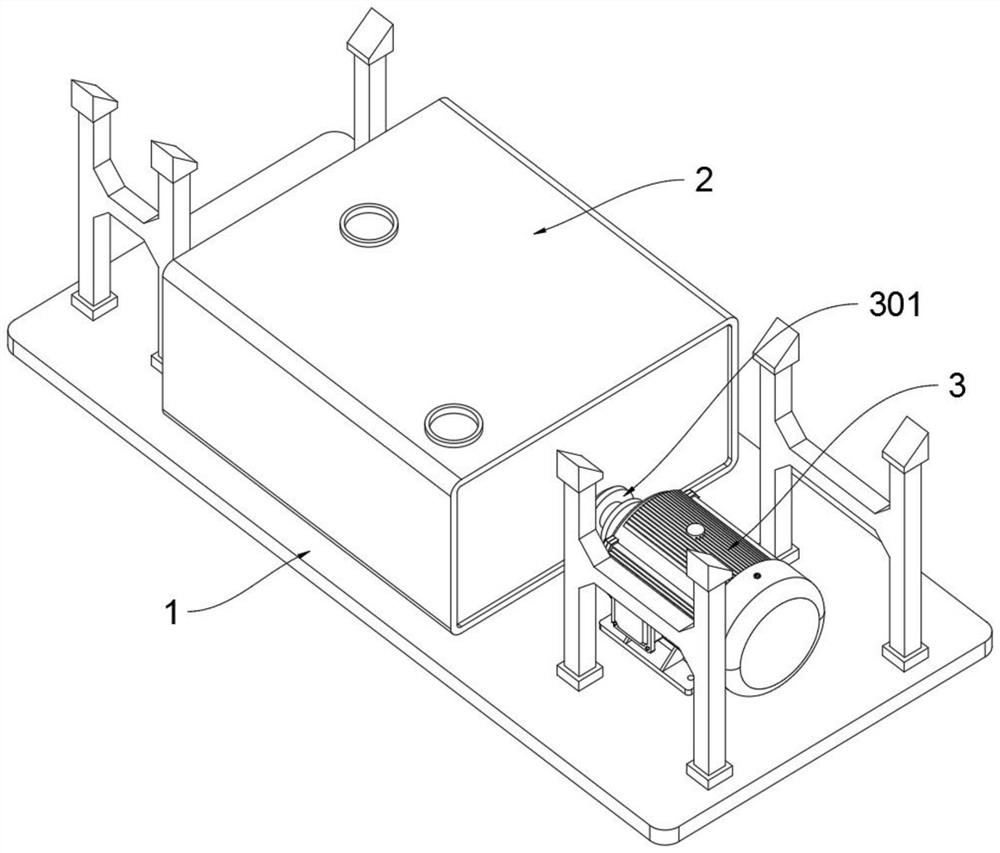

[0046] An oil tank 2 is installed on the top of the base 1, and an oil supply assembly is installed on the front end of the top of the base 1;

[0047] The front oil sump 5 is installed on the top of the front end of the base 1, and the front oil sump 5 is connected to the top of the oil supply assembly;

[0048] The rear oil collection tank 6 is installed on the top of the rear end of the base 1, and the rear oil collection tank 6 is connected with the scraper assembly through bolts 16;

[0049] The collection pipe 7 is connected to the top of the fuel tank 2;

[0050] The guide support pipe 8 is installed at the front end of the front oil sump 5;

[0051] The inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com