Rolling method of sulfur-containing free-cutting stainless steel wire rod

A stainless steel plate and easy-cutting technology, applied in metal rolling, manufacturing tools, furnaces, etc., can solve the problems that no clear improvement measures are given, affecting the product qualification rate and yield rate, etc., so as to shorten the production process and save solid Dissolution treatment link, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

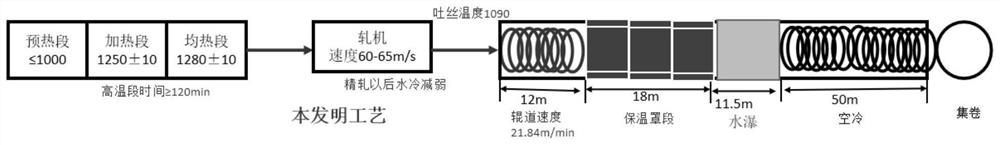

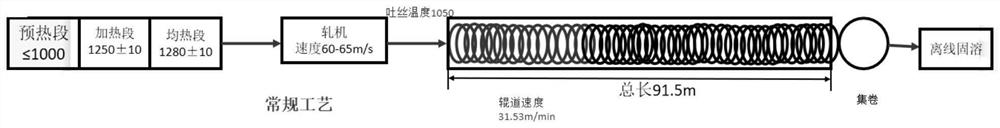

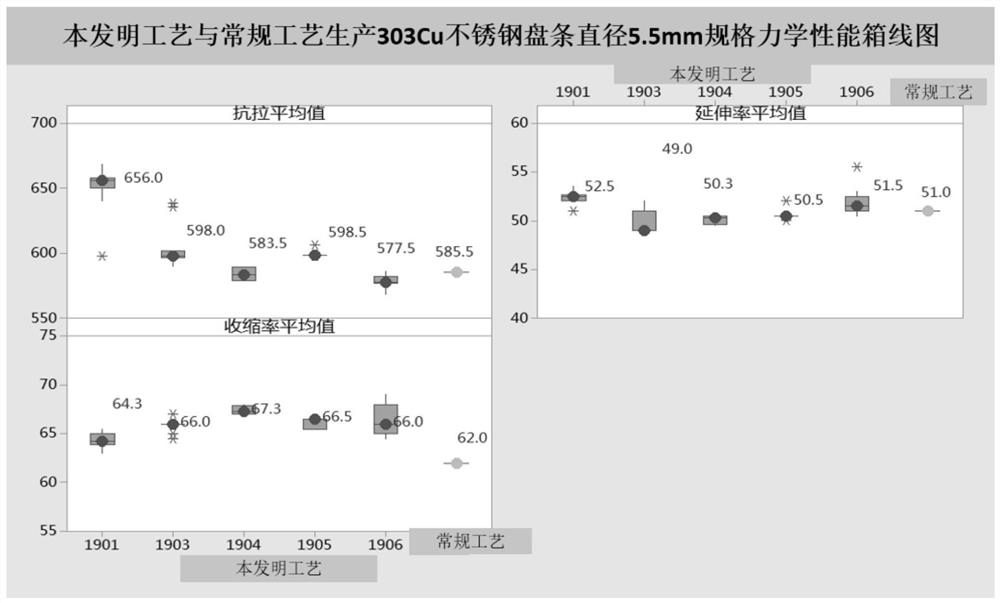

[0040] Apply a kind of rolling method of technology provided by the invention to produce 303Cu stainless steel wire rod, comprising the following steps:

[0041] Step 1. Formulate the heating furnace process according to the characteristics of the steel grade, and the high temperature section is 15 minutes longer than the conventional process;

[0042] Step 2. Reduce the speed of the roller table after spinning from 32m / min to 21m / min, so that the wire rod can be further accumulated compared with the conventional process and reduce the loss of heat;

[0043] Step 3: After spinning, cover the roller table with a heat preservation cover to reduce heat loss and realize the heat preservation effect of offline solid solution;

[0044] Step 4: Add a water explosion device at the outlet of the insulation cover to realize the water quenching effect of offline solid solution;

[0045]Step 5. Collect volumes and roll off the assembly line according to the conventional process.

[0046...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com