Method and device for synchronously machining complex curved surface in additive and subtractive double-station mode

A technology of simultaneous processing and complex curved surfaces, applied in additive processing, solid material additive processing, processing and manufacturing, etc., to achieve the effect of shortening the processing process, facilitating handling and movement, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

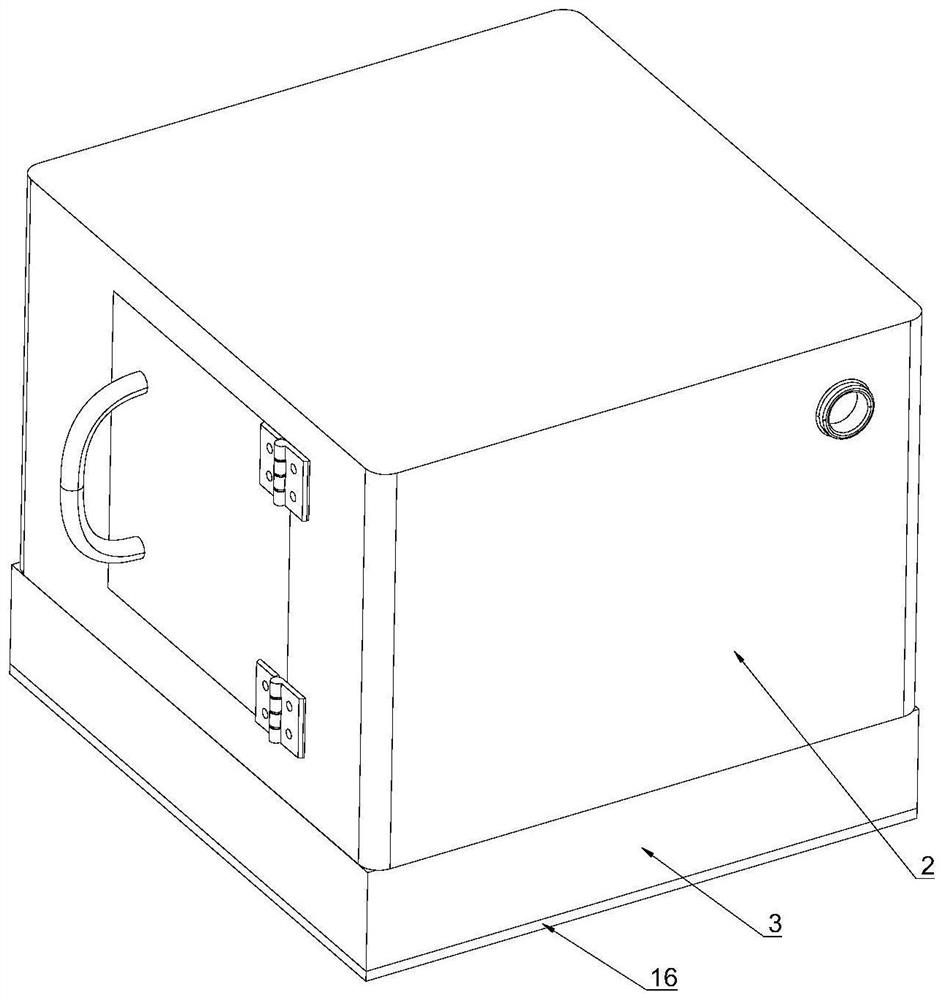

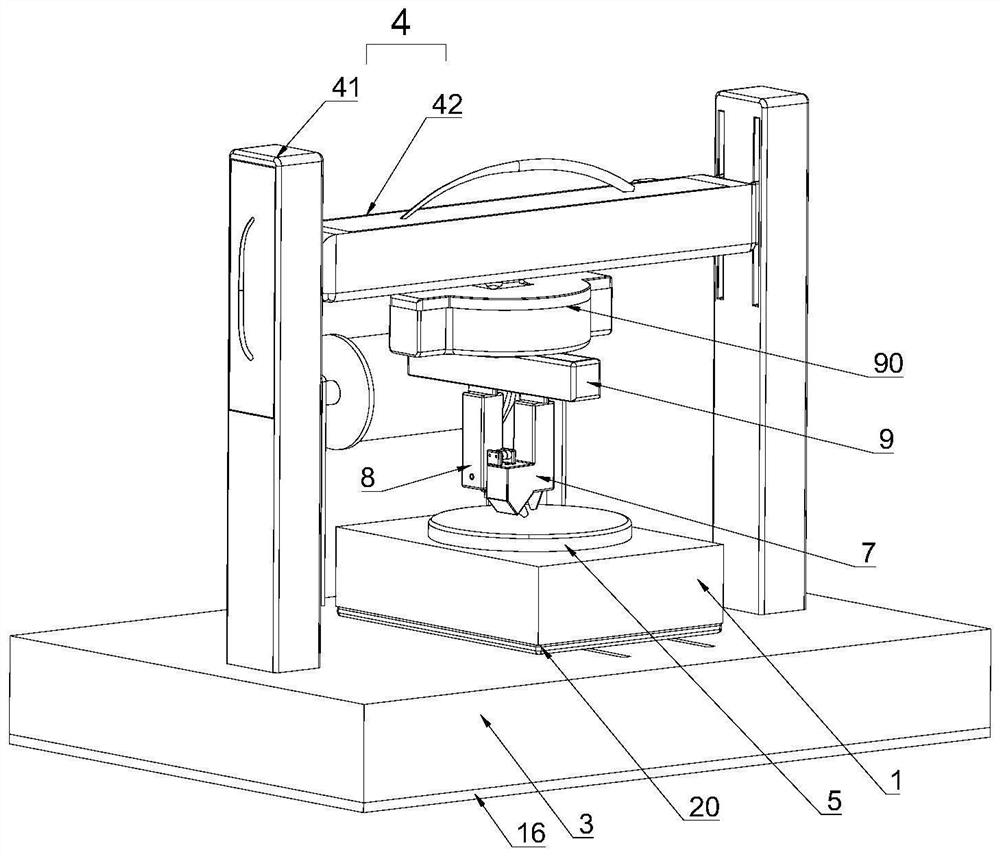

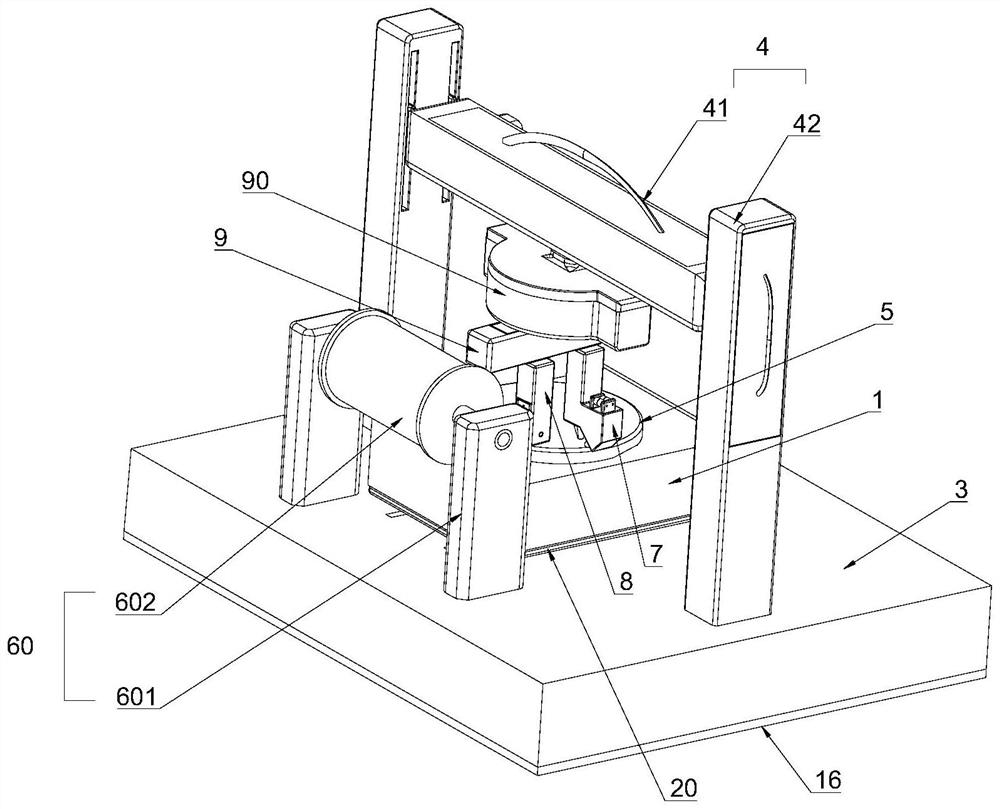

[0077] Such as Figures 1 to 30As shown, a device of the present invention for synchronously processing complex curved surfaces with dual stations for adding and subtracting materials includes a gantry crane 4, a material adding module 7, a grinding and cutting material module 8, and a composite working platform. The composite working platform includes a rotating platform assembly and a translation platform Assemblies, the rotary platform assembly includes a first base 1, a second rotary drive mechanism 11 and a rotary table 5, the rotary table 5 is installed on the first base 1, and the second rotary drive mechanism 11 is used to drive the rotary table 5 relative to The first base 1 rotates; the translation platform assembly includes a second base 3, a translation drive mechanism 6 and a translation workbench 20, the translation workbench 20 is installed above the second base 3, and the translation drive mechanism 6 is used to drive the translation workbench 20 relative to Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com